2026 Best Stainless Steel Solenoid Valve Options for Your Needs?

As industries evolve, the demand for reliable components like the stainless steel solenoid valve grows. According to a recent report by the Global Valve Market Research Institute, the stainless steel valve market is projected to reach $4.5 billion by 2026, highlighting its essential role in fluid control systems. Experts emphasize the need for durability and efficiency in these systems. "Choosing the right solenoid valve can drastically improve operational efficiency," says Dr. John Stevens, a leading expert in fluid dynamics.

In today's market, not all stainless steel solenoid valves are created equal. While some brands boast high performance, others may fall short. The journey to find the best valve requires careful consideration and analysis. Many buyers overlook the importance of specifications, leading to costly mistakes and inefficiencies in operations.

It's vital to understand the technicalities involved in selecting a stainless steel solenoid valve. Quality assurance is not just an option; it's a necessity. Manufacturers must ensure their products meet stringent quality standards. A lack of attention to detail can result in failures that disrupt production. The quest for the ideal solenoid valve is ongoing, fueled by constant technological advancements and changing industry needs. This dynamic landscape presents both challenges and opportunities for those in the market.

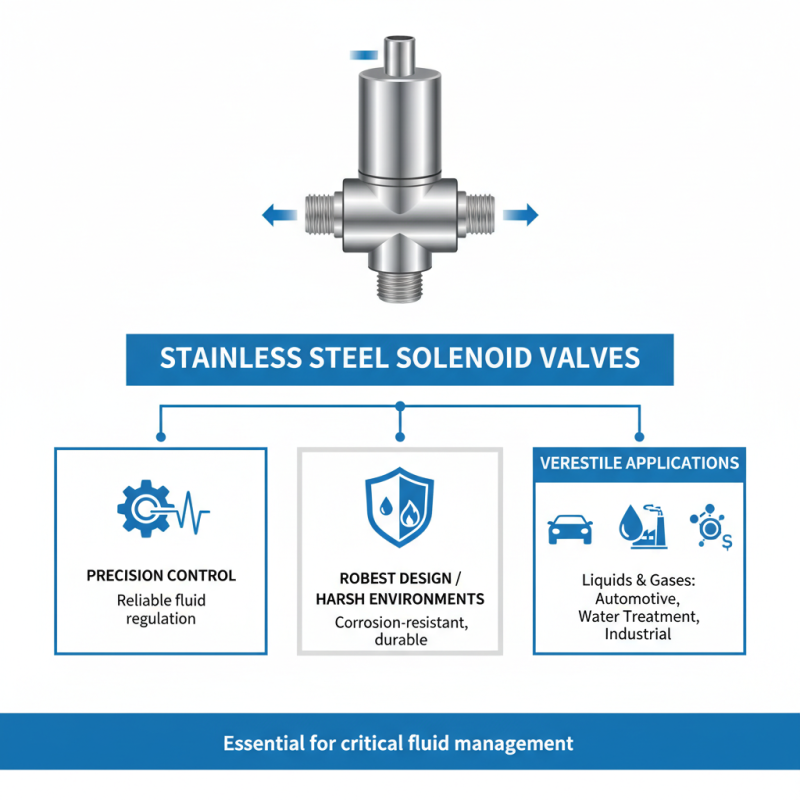

2026 Overview of Stainless Steel Solenoid Valve Types and Applications

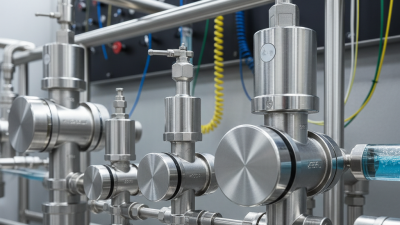

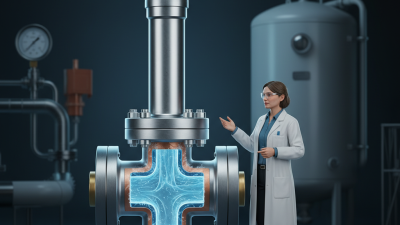

Stainless steel solenoid valves are essential in various industries. They control fluid flow with precision and reliability. Their robust design makes them ideal for harsh environments. Applications range from automotive systems to water treatment facilities. They can handle both liquids and gases, which increases their versatility.

Different types of stainless steel solenoid valves exist. Normally closed valves prevent flow when not energized. Alternatively, normally open valves allow flow unless activated. This distinction is crucial for specific applications. Many engineers struggle with choosing the right type for their needs. Understanding the operating environment is often overlooked.

Furthermore, maintenance can be a challenge. Regular inspections are critical to ensure optimal performance. Corrosion, despite stainless steel's durability, can still be an issue. Users sometimes neglect this aspect, leading to failures. Reflecting on these factors enhances long-term functionality and reliability.

Key Factors Influencing the Selection of Stainless Steel Solenoid Valves

When selecting stainless steel solenoid valves, several key factors come into play. The first aspect to consider is the valve's pressure rating. Different applications require specific pressure tolerances. It's crucial to assess the pressure needs of your system before making a decision. A mismatched valve can lead to leaks or failures.

Another important factor is the coil specifications. The coil voltage and power ratings must align with your application. For instance, high frequencies may require special coils. It’s easy to overlook this detail, but ignoring it can result in inefficiencies. Also, assess the valve’s response time. Rapid response is vital in many processes, particularly in automation.

Material compatibility is essential as well. Stainless steel offers corrosion resistance, but not all grades are suitable for every medium. Knowing the chemicals involved in your system is necessary. Sometimes, a standard choice may not withstand certain conditions. Keep in mind that cost can also influence your choice. It's tempting to select the cheapest option, yet quality should never be sacrificed. Overall, making the right choice requires careful consideration of these factors.

Industry Standards and Certifications for Stainless Steel Solenoid Valves

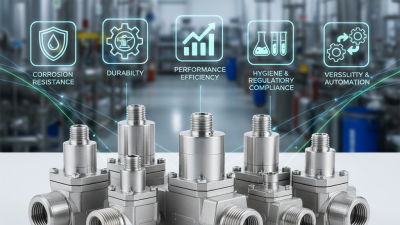

When selecting stainless steel solenoid valves, industry standards and certifications play a crucial role. These valves must meet specific guidelines to ensure reliability and safety in various applications. Common certifications include ISO, CE, and UL. Each shows that the valve has undergone rigorous testing. These validations highlight the importance of quality and performance.

Different sectors like pharmaceuticals and food processing have stringent requirements. For instance, valves used in these industries need to be corrosion-resistant and easy to clean. The materials and design must comply with hygienic standards. Not every supplier meets these requirements, so it's vital to research.

However, not all valves labeled as compliant are created equal. Some might meet minimum standards but lack durability. Users may find themselves needing replacements sooner than expected. It’s essential to balance cost with quality. Sometimes, the cheapest option isn't the best long-term investment. Familiarizing yourself with testing reports and user reviews can prevent future headaches.

Comparative Analysis of Leading Manufacturers in 2026 Stainless Steel Valves

In 2026, the market for stainless steel solenoid valves continues to grow, driven by demand across various industries. Recent reports indicate that the global solenoid valve market is projected to reach $5 billion by 2027. This growth reflects the increasing adoption of automation in sectors like manufacturing and HVAC. Stainless steel valves offer durability and resistance to corrosion, making them a favored choice.

A comparative analysis of leading manufacturers reveals varying approaches. Some companies emphasize cutting-edge technology to enhance performance. Others focus on cost-effectiveness, often compromising on material quality. Data from industry studies show that 40% of users prioritize long-term reliability over initial costs. It’s a balance that manufacturers must navigate.

The challenge lies in achieving optimal design and functionality. A significant portion of solenoid valves in use today does not meet industry standards. Insufficient quality control can lead to failures in critical applications. This highlights the need for ongoing evaluation and improvement. Many consumers are unaware of how this affects operational efficiency. Selecting the right manufacturer requires careful consideration of performance, cost, and reliability.

2026 Best Stainless Steel Solenoid Valve Options for Your Needs

| Model | Size (inches) | Pressure Rating (psi) | Temperature Range (°F) | Flow Rate (GPM) | Actuation Type |

|---|---|---|---|---|---|

| SV-101 | 1/2 | 150 | -10 to 180 | 10 | Electric |

| SV-102 | 3/4 | 200 | -4 to 195 | 15 | Pneumatic |

| SV-103 | 1 | 250 | 0 to 180 | 20 | Electric |

| SV-104 | 1 1/4 | 300 | -10 to 200 | 25 | Pneumatic |

| SV-105 | 1 1/2 | 150 | -20 to 180 | 30 | Electric |

Cost-Benefit Analysis of Stainless Steel Versus Other Valve Materials

When assessing the cost-benefit analysis of stainless steel solenoid valves versus other materials, several factors come into play. Stainless steel is known for its exceptional durability and resistance to corrosion. This makes it an ideal choice for various industrial applications. However, it often comes with a higher price tag compared to alternatives.

Materials like plastic or brass can be significantly cheaper. They may work well but lack the robustness of stainless steel. Over time, cheaper options may lead to frequent replacements. This can increase long-term costs. Stainless steel valves, despite their initial investment, often require less maintenance and offer better performance.

It's essential to evaluate the specific needs of your system. Consider factors like pressure levels, temperature, and chemical exposure. What works for one application may not suit another. Be mindful of the environment. A robust choice may endure longer, but in some cases, less expensive options might suffice. The decision should balance upfront costs with long-term reliability.

Cost-Benefit Analysis of Stainless Steel Solenoid Valves vs. Other Valve Materials

Related Posts

-

Top Tips for Choosing and Maintaining Stainless Steel Solenoid Valves

-

Top 5 Benefits of Using Stainless Steel Solenoid Valves in Industry

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

-

What is a Cryogenic Valve and How Does it Work?

-

Understanding the Importance of Relief Valves in Modern Industrial Applications