2026 Top Vacuum Relief Valve Innovations and Their Applications?

In the rapidly evolving world of industrial applications, the vacuum relief valve plays a crucial role. This essential component ensures safety and efficiency in various systems. With increased innovation on the horizon, 2026 promises exciting developments in vacuum relief valves.

These devices help prevent vacuum conditions that could lead to equipment failure. Modern designs incorporate advanced materials and technologies. A shift towards automation and smart systems brings new functionalities. However, despite these innovations, challenges remain. Not all vacuum relief valves are created equal. Some may not meet the demands of every specific application.

As industries push for greater efficiency and sustainability, vacuum relief valves must adapt. Understanding the new innovations allows for better applications and improved systems. What features will define the next generation of vacuum relief valves? Addressing these questions leads to deeper insights into their future.

2026 Innovations in Vacuum Relief Valve Technology

The year 2026 promises significant advancements in vacuum relief valve technology. Innovations are emerging to enhance safety and efficiency in various applications. These valves play a crucial role in preventing vacuum conditions that can jeopardize equipment integrity. Smart technology is now integrated into these valves, providing real-time monitoring. This improvement helps detect pressure changes quickly.

Some designs now feature advanced materials that withstand extreme conditions. This innovation leads to more durable and reliable valves. However, the application of these materials requires thorough testing. Some valves may still experience unexpected failures under specific circumstances. Thus, continuous research is necessary to refine their reliability.

Further, user-friendly interfaces are being developed for ease of control. This is a significant step toward better usability. Operators often struggle with complex systems. Innovations aim to simplify these challenges. Still, not all designs achieve this balance between functionality and simplicity. It's essential to reflect on user experiences to guide future improvements. Understanding the practical implications of these innovations will drive further progress in vacuum relief valve technology.

Key Features of Next-Generation Vacuum Relief Valves

Next-generation vacuum relief valves are transforming various industries. These innovations focus on improving safety and efficiency. According to a recent industry report, the global market for vacuum relief valves is expected to reach $600 million by 2026. This highlights the growing demand and importance of advanced technologies in this sector.

Key features include enhanced response times and adjustable pressure settings. The valves are now equipped with better materials, minimizing wear and tear. Some models also offer integrated sensors for real-time monitoring. These advancements can lead to reduced downtime and maintenance costs. Recent tests show that modern valves can improve system reliability by up to 30%.

Despite these improvements, challenges remain. Not all industries have adapted to these innovations. Smaller operations may still rely on outdated technology. This transition poses risks, as older valves may fail under varying conditions. The need for proper training in new technologies cannot be overstated. As industries continue to evolve, the focus must shift towards educating personnel on these advancements for optimal performance.

2026 Top Vacuum Relief Valve Innovations and Their Applications - Key Features of Next-Generation Vacuum Relief Valves

| Innovation | Key Features | Applications | Materials Used | Temperature Range |

|---|---|---|---|---|

| Smart Pressure Relief System | Real-time monitoring, automated adjustments | Chemical processing, food preservation | Stainless steel, PTFE | -40 to 150°C |

| Biochemical Safety Valve | Leak-proof design, anti-corrosive materials | Pharmaceuticals, biotech labs | Hastelloy, glass-lined | -20 to 120°C |

| Energy-Efficient Vacuum Valves | Low power consumption, improved sealing | HVAC systems, solar energy systems | Aluminum, rubber | -30 to 100°C |

| Advanced Sensor Technology | Integrated sensors for pressure and flow | Oil and gas, waste management | Titanium alloys, polymers | -50 to 200°C |

| Quick-Release Vacuum Valves | Rapid closure mechanisms, user-friendly | Manufacturing, packaging | Nylon, stainless steel | 0 to 80°C |

Applications of Vacuum Relief Valves in Various Industries

Vacuum relief valves are essential in various industries, ensuring safety and efficiency. These valves help prevent vacuum conditions that can lead to catastrophic failures. According to a 2022 report by Global Market Insights, the vacuum relief valve market is projected to reach $3.5 billion by 2027, highlighting their increasing importance.

In the pharmaceutical industry, these valves are crucial for protecting sensitive equipment. They prevent collapse during processes like filling and packaging. Without proper vacuum relief, products may become contaminated or unusable. Data from the International Society for Pharmaceutical Engineering indicates that proper valve installation can reduce downtime by up to 25%. Such improvements indicate a need to focus on the integrity of these systems.

Similarly, in the food processing sector, vacuum relief valves play a vital role. They ensure that containers remain intact during sterilization processes. Research shows that improper usage can lead to food spoilage or waste. A study by the Food and Drug Administration noted that nearly 15% of recalls are related to packaging failures. This data points to an ongoing issue: companies must reassess their valve systems to prevent losses and ensure safety.

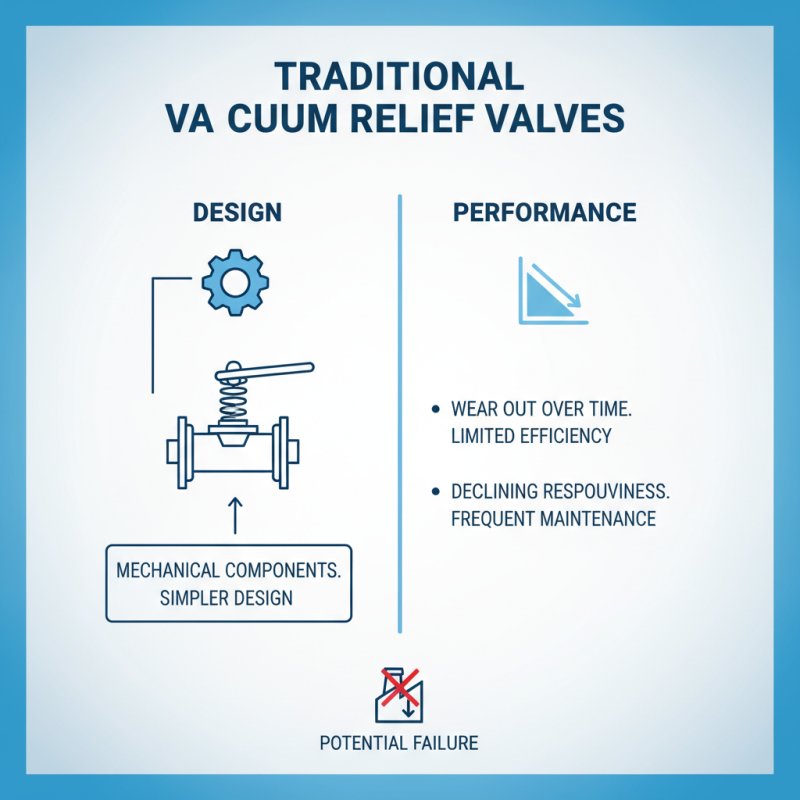

Comparative Analysis of Traditional vs. Innovative Valves

Innovations in vacuum relief valves are changing the landscape of various industries. Traditional vacuum relief valves often rely on mechanical components. These components can wear out, leading to potential failure. Their design is usually simpler, but this can limit efficiency and responsiveness. Over time, the performance of these traditional valves can decline, requiring frequent inspections and maintenance.

In contrast, innovative vacuum relief valves incorporate advanced materials and sensor technology. These new designs offer improved reliability and faster response times. For instance, some innovative valves operate using smart technology that can automatically adjust to pressure changes. This results in enhanced safety and operational efficiency. However, these technologies are not without flaws. Integration into existing systems can be challenging. Maintenance may require specialized knowledge, which is a drawback for some users.

Ultimately, the choice between traditional and innovative vacuum relief valves depends on specific applications and user needs. While innovative options present exciting capabilities, they also bring new complexities. Understanding these trade-offs is crucial for making an informed decision. Users must weigh the benefits against potential operational hurdles.

Future Trends in Vacuum Relief Valve Development and Use

As the demand for efficient vacuum systems increases, innovations in vacuum relief valves are emerging. These valves play a crucial role in protecting equipment from damage caused by vacuum pressure. In 2026, we can expect innovations that enhance their operational efficiency. New materials may improve durability while reducing maintenance needs. Advanced designs can allow for quicker response times when pressure changes occur, preventing potential hazards.

Future trends indicate a shift towards automation and smart technology integration. Sensors embedded within valves can provide real-time data on system performance. This data can help in predictive maintenance, reducing unexpected downtimes. However, the integration of technology raises questions about reliability. Will these systems be robust enough for demanding environments? Some may argue that excessive reliance on automation can lead to oversight in manual checks.

Additionally, the increasing focus on sustainability may drive the development of eco-friendly materials. Current designs often utilize metals that have significant environmental footprints. Exploring biodegradable options could revolutionize the industry. However, transitioning to such materials also presents challenges. The durability and effectiveness of new materials must be verified. Balancing innovation with practical application is crucial for future success.

2026 Top Vacuum Relief Valve Innovations and Their Applications

This chart displays the projected advancements and their applications in vacuum relief valve technology by 2026. The data includes the innovation types and their expected prevalence in various industries.

Related Posts

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

2026 Best Stainless Steel Solenoid Valve Options for Your Needs?

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

2026 How to Choose the Right Solenoid Valve for Your Application?

-

10 Essential Tips for Choosing the Right High Pressure Valve