Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

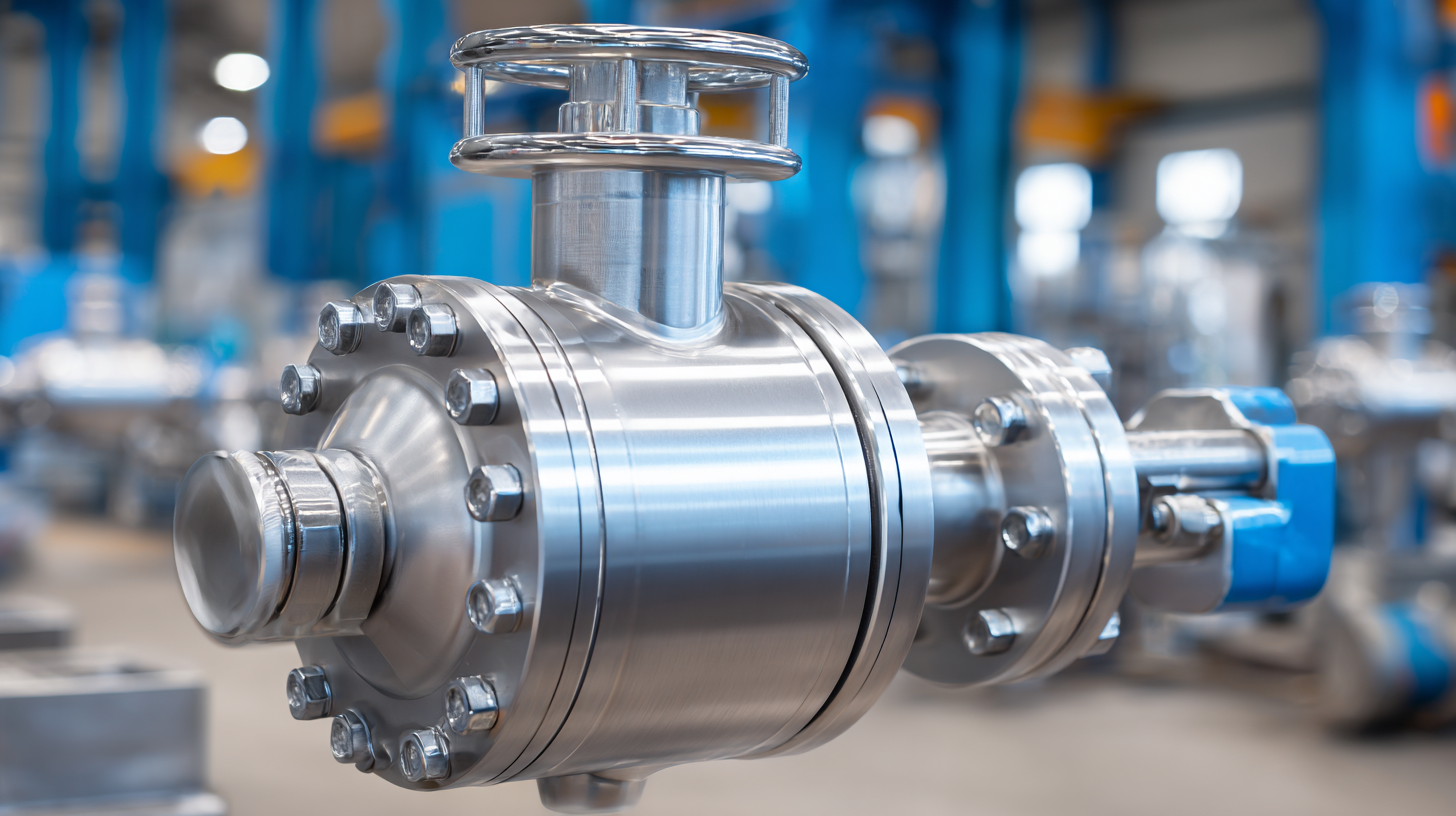

In the realm of plumbing solutions, the importance of selecting the right valve cannot be understated, and stainless ball valves have emerged as a favorite among industry professionals. According to a recent report by Freedonia Group, the demand for stainless steel valves is expected to grow at an annual rate of 6.4% through 2025, driven by the increasing need for durable and reliable plumbing components. Stainless ball valves are particularly valued for their robustness, corrosion resistance, and ability to maintain a tight seal under high-pressure conditions. These advantages make stainless ball valves an essential choice for various applications, from residential plumbing to industrial systems.

As we delve deeper into the benefits of stainless ball valves, it becomes clear that they not only enhance the efficiency and longevity of plumbing systems but also provide cost-effective solutions that align with modern sustainability goals.

Benefits of Stainless Ball Valves in Plumbing: A Comprehensive Overview

Choosing stainless ball valves for plumbing applications offers numerous benefits that are crucial for both residential and commercial settings. One standout advantage is their resistance to corrosion. According to the Corrosion Engineering Report (2022), stainless steel valves exhibit a minimum lifecycle that can extend up to 30 years when properly maintained, far outlasting traditional brass or PVC options that may weaken over time. This durability not only assures longevity but also significantly reduces the frequency and cost of replacements, making them a cost-effective solution in the long run.

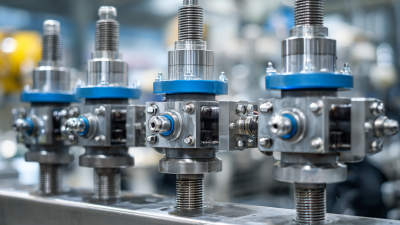

Moreover, stainless ball valves provide excellent flow control and minimal pressure drop in pipelines. The American Society of Mechanical Engineers (ASME) indicates that stainless ball valves have a lower torque requirement, allowing for quicker operation and reduced wear on associated equipment. This efficiency can lead to less energy consumption in pumping systems, further enhancing overall system performance.

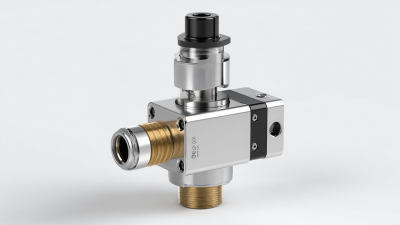

**Tip:** When selecting stainless ball valves, ensure they have a dual sealing mechanism to further minimize leaks. This feature is especially crucial in high-pressure applications. Also, consider the valve size carefully; an oversized valve may create a risk of cavitation, which can damage the valve and system over time.

| Benefit | Description | Applications | Material Properties |

|---|---|---|---|

| Corrosion Resistance | Stainless steel valves resist rust and corrosion, leading to longer service life. | Water Supply, Chemical Transport | Commonly made from 304 or 316 grade stainless steel. |

| Durability | Withstands high pressure and temperature fluctuations. | Heating Systems, Industrial Applications | High tensile strength and impact resistance. |

| Ease of Operation | Quick 90-degree turn to open or close, providing fast flow control. | Residential and Commercial Plumbing | Smooth ball mechanism ensures minimal torque requirements. |

| Low Maintenance | Self-sealing design reduces leaks with lower maintenance needs. | Waste Management Systems | Sealed seats minimize wear and degradation over time. |

| Versatility | Applicable in a wide range of media, including gases and liquids. | Food Processing, Pharmaceutical Industries | Compatible with various pressure and temperature specifications. |

Durability Comparison: Stainless Ball Valves vs. Traditional Valves in Plumbing

Stainless ball valves have emerged as a preferred choice in plumbing applications due to their outstanding durability compared to traditional valve materials. While older valve types made from brass or plastic may serve their purpose, they are often susceptible to corrosion and wear over time, leading to leaks and costly repairs.

In contrast, stainless steel ball valves offer superior resistance to corrosion, pressure, and temperature fluctuations, ensuring a longer lifespan and reliable performance. This durability support aligns with recent data forecasting that the North America residential ball valves market will hit USD 652.2 million by 2035, largely driven by increasing residential construction demand.

Moreover, as plumbing systems become increasingly sophisticated, the demand for high-quality valves continues to rise. Stainless ball valves not only provide the durability needed to maintain system integrity but also contribute to overall efficiency in water management. Reports indicate that advancements in valve technology, including the introduction of ceramic core ball valves, are further enhancing the reliability and performance of plumbing components.

As the global plumbing sector expands, understanding the benefits of choosing stainless ball valves over traditional options becomes crucial for homeowners and builders alike, ensuring they invest in solutions that offer both longevity and effectiveness.

Corrosion Resistance: Industry Statistics on Stainless Steel Performance

Stainless steel ball valves are increasingly recognized for their exceptional corrosion resistance, a crucial factor for plumbing systems exposed to harsh environments. According to market forecasts, the stainless steel seamless pipes market is expected to grow from USD 3.37 billion in 2024 to USD 5.15 billion by 2030, representing a compound annual growth rate (CAGR) of 5.8%. This growth underscores the rising demand for durable and reliable materials in plumbing applications, particularly in industries where corrosion can significantly impact performance and longevity.

Industry statistics reveal that stainless steel, known for its resistance to rust and chemical degradation, outperforms other materials in various corrosive settings. This is especially relevant for plumbing systems, where exposure to water and other elements can lead to rapid material degradation. Reports indicate that the global stainless steel market will continue to thrive, driven by its applications across diverse sectors such as construction, automotive, and oil and gas. As industries continue to prioritize reliability and maintenance reduction, the choice of stainless steel ball valves is likely to become even more prominent in plumbing design and application.

Flow Efficiency: How Stainless Ball Valves Optimize Water Flow in Plumbing Systems

Stainless ball valves have become a go-to choice for plumbing systems, primarily due to their exceptional flow efficiency. These valves can maintain a straight-through flow path, minimizing turbulence and pressure loss, which is crucial for optimizing water flow in various applications. Recent studies indicate that the design of ball valves allows for a significantly lower pressure drop compared to traditional gate valves, making them ideal for both residential and industrial plumbing setups. For instance, the Thomas Industry Overview highlights that properly functioning valves can increase system efficiency by up to 30%, contributing to greater overall energy savings.

Moreover, the hydrodynamic characteristics of stainless ball valves ensure a robust and consistent flow rate. Unlike gate valves, which can experience flow separation and turbulence, ball valves offer smooth transitions that reduce the likelihood of cavitation and improve the longevity of the plumbing system. According to experimental investigations, the streamlined design correlates directly with enhanced flow rates, allowing for better performance in high-demand environments. As a result, selecting stainless ball valves not only supports optimal water flow but also plays a key role in the reliability and sustainability of plumbing systems.

Cost-Effectiveness: Long-Term Savings with Stainless Ball Valves in Plumbing Applications

When considering plumbing solutions, stainless ball valves present a compelling case for cost-effectiveness. Unlike traditional valves, stainless ball valves are designed for durability and longevity, which reduces the frequency of replacements and repairs. Their resistance to corrosion and wear ensures that they maintain optimal performance even in challenging environments, leading to lower long-term maintenance costs. This makes them an ideal choice for both residential and industrial plumbing applications, where the initial investment can yield significant savings over time.

The increasing demand for high-quality plumbing components is reflected in market trends, particularly in residential construction. With the uptick in new builds and renovations, the preference for stainless ball valves is on the rise. Their ability to facilitate efficient fluid control not only enhances system performance but also aligns with the growing focus on sustainability in plumbing practices. As more businesses and homeowners recognize the long-term financial benefits, the shift towards stainless ball valves becomes increasingly evident, marking them as an essential component for future plumbing projects.

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

Related Posts

-

Understanding the Importance of Control Valves in Modern Industrial Applications

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency