Top 5 Benefits of Using Stainless Steel Solenoid Valves in Industry

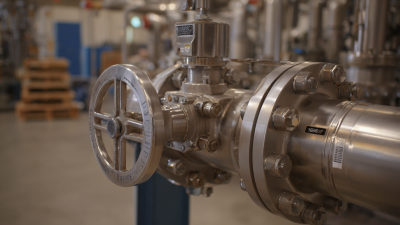

The use of stainless steel solenoid valves in various industrial applications has increasingly gained traction due to their superior corrosion resistance, durability, and performance efficiency. According to a recent market study by Grand View Research, the global solenoid valve market is expected to reach USD 4.9 billion by 2025, exhibiting a compound annual growth rate (CAGR) of 5.2%. Stainless steel solenoid valves play a crucial role in this growth, driven by their ability to withstand harsh environments while maintaining reliability in critical operations.

Moreover, data from industry reports indicate that stainless steel solenoid valves are preferred in sectors such as oil and gas, chemical processing, and food and beverage due to their ability to meet stringent regulatory standards for durability and hygiene. The versatility of these valves allows them to handle a wide range of fluids and gases, which further solidifies their position as a vital component in automated systems. As industries continue to prioritize efficiency and sustainability, the benefits of incorporating stainless steel solenoid valves into their operations are becoming increasingly evident, making them an essential investment for future growth.

Benefits of Corrosion Resistance in Stainless Steel Solenoid Valves

Stainless steel solenoid valves are increasingly recognized for their exceptional corrosion resistance, making them a vital component in various industrial applications. This intrinsic quality allows these valves to function reliably in environments where exposure to moisture, chemicals, and harsh elements is common. The ability of stainless steel to resist rust and degradation significantly prolongs the lifespan of solenoid valves, thereby reducing maintenance costs and minimizing unplanned production downtime.

In industries such as oil and gas, food processing, and pharmaceuticals, the impact of corrosion can be detrimental. Corrosion not only weakens the structural integrity of valves but also poses serious safety risks and compromises product quality. Stainless steel solenoid valves mitigate these risks effectively, maintaining performance under pressure and in extreme temperatures. The smooth surface finish of stainless steel also helps prevent the buildup of contaminants, ensuring a clean flow through the system. This reliable performance reinforces the importance of using corrosion-resistant materials in critical applications, underscoring the advantage of stainless steel solenoid valves in maintaining operational efficiency and safety standards.

Enhanced Durability and Longevity of Industrial Applications

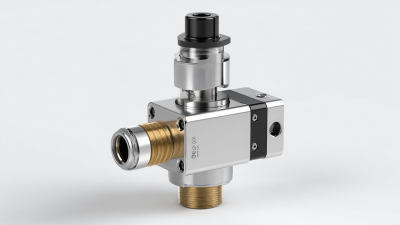

Stainless steel solenoid valves are increasingly favored in industrial applications due to their enhanced durability and longevity. One of the primary advantages of utilizing stainless steel in valve construction is its resistance to corrosion and rust. In environments where exposure to moisture, chemicals, or extreme temperatures is common, traditional materials may degrade rapidly, leading to costly replacements and downtime. The robust nature of stainless steel ensures that these valves can withstand harsh conditions, maintaining operational integrity over extended periods.

Moreover, the longevity of stainless steel solenoid valves directly contributes to reduced maintenance costs and improved efficiency in industrial operations. The ability to function reliably without frequent repairs translates to less disruption in workflow and a significant reduction in operational costs. Industries that require precision and reliability, such as manufacturing and chemical processing, benefit considerably as they can count on stainless steel valves to perform consistently without compromising safety or effectiveness. With such resilient materials, businesses can enhance their overall productivity by eliminating the challenges linked to valve failure and replacement.

Improved Hygiene Standards in Fluid Control Systems

In modern industrial applications, maintaining high hygiene standards within fluid control systems is paramount, particularly in sectors such as food and beverage, pharmaceuticals, and healthcare. Stainless steel solenoid valves are increasingly recognized for their ability to enhance these hygiene standards effectively. With their non-porous surfaces and resistance to corrosion, stainless steel materials significantly reduce the risk of contamination, ensuring that substances flowing through the valves remain uncontaminated and pure.

According to a report by the International Association for Food Protection, up to 70% of foodborne illnesses can be traced back to inadequate hygienic practices in processing environments. Stainless steel solenoid valves, by minimizing bacteria adhesion and simplifying cleaning procedures, play a critical role in mitigating these risks. Furthermore, their ability to withstand high-temperature sterilization processes makes them ideal for use in sterile environments where hygiene is critical. A study from the European Commission indicated that facilities employing such valves saw a 30% reduction in contamination rates, underscoring their effectiveness in maintaining stringent hygiene protocols.

The longevity and durability of stainless steel solenoid valves also contribute to sustained cleanliness in industrial systems. Unlike plastic or other materials that may degrade over time and harbor contaminants, stainless steel valves maintain their integrity, requiring less frequent replacements. This not only helps in reducing downtime and maintenance costs but also supports ongoing compliance with hygiene regulations, as noted in the recent report by the World Health Organization, which emphasizes the need for robust and reliable components in maintaining the quality and safety of industrial processes.

Top 5 Benefits of Using Stainless Steel Solenoid Valves in Industry - Improved Hygiene Standards in Fluid Control Systems

| Benefit | Description | Industry Applications |

|---|---|---|

| Enhanced Corrosion Resistance | Stainless steel provides significant resistance to rust and corrosion, ensuring longevity and reliability in harsh environments. | Food and Beverage, Pharmaceutical |

| Improved Hygiene | The non-porous surface of stainless steel makes it easier to clean and sterilize, reducing the risk of contamination. | Medical Equipment, Water Treatment |

| Higher Temperature Tolerance | Stainless steel valves can withstand higher temperatures compared to other materials, allowing for versatile applications. | Oil and Gas, Chemical Processing |

| Durability and Strength | These valves are built to endure high pressures and impacts, leading to a reduction in maintenance and replacement costs. | Manufacturing, Construction |

| Wide Chemical Compatibility | Stainless steel is compatible with a range of chemicals, making it suitable for various fluid control systems. | Pharmaceutical, Waste Management |

Versatility and Adaptability Across Various Industries

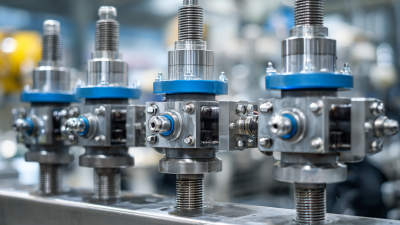

Stainless steel solenoid valves are increasingly recognized for their exceptional versatility and adaptability, making them indispensable in various industrial applications. Their corrosion resistance allows them to thrive in harsh environments, such as chemical processing plants and wastewater treatment facilities. This durability ensures reliable performance over an extended lifespan, helping industries reduce downtime and maintenance costs. Furthermore, stainless steel valves can handle a wide range of fluids, including aggressive chemicals and high-temperature substances, highlighting their broad application spectrum.

Additionally, the compatibility of stainless steel solenoid valves with multiple control systems enhances their adaptability. They can be seamlessly integrated into automated systems, making them suitable for industries such as manufacturing, food processing, and pharmaceuticals. This integration capability allows for more efficient operations and precision in fluid control, which is critical in ensuring consistent product quality. As industries strive for increased efficiency and sustainability, the ability of stainless steel solenoid valves to function effectively across diverse settings positions them as a top choice for engineers and project managers alike.

Cost-Effectiveness and Maintenance Advantages of Stainless Steel Valves

Stainless steel solenoid valves are increasingly recognized in various industrial applications for their cost-effectiveness and low maintenance requirements. According to a report by Research and Markets, the global solenoid valve market is projected to reach USD 2.6 billion by 2025, driven by the increasing demand for efficiency in automation processes. The durability of stainless steel against corrosion and wear makes these valves a reliable choice, particularly in industries such as chemical processing and wastewater management, where exposure to harsh environments is a significant concern.

The maintenance advantages of stainless steel solenoid valves stem largely from their robust construction. A study by the International Journal of Advanced Manufacturing Technology highlights that stainless steel valves can significantly reduce downtime due to fewer maintenance cycles, with a lifespan estimated to be five to ten years longer compared to traditional materials. This not only lowers operational costs but also enhances productivity, as systems remain operational for extended periods without the need for frequent repairs or replacements. In environments where efficiency is paramount, the selection of stainless steel solenoid valves can provide both economic and operational benefits, ensuring that industries maintain their competitive edge while managing costs effectively.

Related Posts

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

Top 10 Essential Valve Tags for Efficient Industrial Safety Management

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs