10 Best Control Valves for Optimal Process Management?

Control valves are essential in various industries, managing fluid flow with precision. According to a recent report by MarketsandMarkets, the global control valve market is projected to reach $14.0 billion by 2025. This growth reflects the increasing demand for optimized process management in sectors like oil & gas, water treatment, and chemical manufacturing.

In these industries, control valves ensure efficient operation. They help maintain the desired pressure, flow rate, and temperature. However, not all control valves are created equal. Choosing the right type can be challenging, as each application demands specific characteristics. A poorly chosen control valve can lead to inefficiencies and increased operational costs. An estimated 25% of industrial energy consumption stems from poorly managed fluid systems, underscoring the importance of proper selection.

Investing in high-quality control valves can enhance reliability and performance. However, companies must remain vigilant about maintenance and potential failures. Regular evaluations are crucial for optimizing performance. The right control valve contributes to increased efficiency and reduced downtime, but the path to optimal selection is not always straightforward.

Overview of Control Valves and Their Importance in Process Management

Control valves play a critical role in process management. They regulate fluid flow, ensuring systems operate efficiently. A well-functioning valve responds quickly to changes in demand. This responsiveness is crucial for maintaining optimal conditions in various industries. They manage pressure and temperature, which directly influence production quality.

However, not all control valves are equally effective. Some may lag in performance, leading to inefficiencies. This can result in inconsistent product output. In industries like pharmaceuticals, precision is vital. A slight error in flow control can affect batch consistency. There’s a need for constant evaluation of valve performance.

Design and material selection are also key considerations. A valve that fits perfectly in one system might fail in another. It’s essential to assess compatibility with the fluid being controlled. Maintenance routines should be established to prevent wear and tear. Neglecting these aspects can lead to costly downtimes. Ultimately, understanding the role of control valves can lead to enhanced process management.

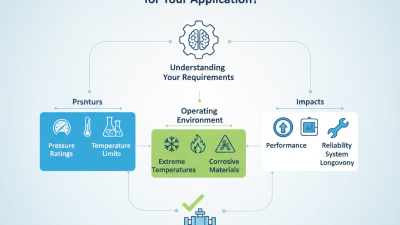

Criteria for Selecting the Best Control Valves for Various Applications

When selecting control valves, industry professionals face numerous challenges. One key factor is the application type. For instance, high-pressure systems may require robust materials that can withstand extreme conditions. According to a 2023 report by the Flow Control Association, materials like stainless steel and exotic alloys are often recommended for these applications.

Sizing is another critical criterion. Poorly sized valves can lead to inefficiencies and increase operational costs. A study from the International Society of Automation indicates that improper sizing can reduce flow efficiency by up to 30%. Valve sizing should consider factors like flow rate and pressure drop to minimize operational issues.

Lastly, consider the control method. Electric or pneumatic actuators may suit different applications better. The choice affects response time and energy consumption. Data from the American Society of Mechanical Engineers highlights that electric actuators can improve precision in certain processes, while pneumatic options may remain vital for larger systems. Such technical nuances reveal the complexity involved in control valve selection.

Top 10 Control Valves: Features and Benefits for Optimal Performance

When selecting control valves, it's crucial to consider their features and benefits. Control valves regulate fluid flow, pressure, and temperature in various processes. The right valve can enhance efficiency and improve system performance. Key features include the ability to withstand high pressures and temperatures. Some valves offer quick response times, which are vital in dynamic processes.

Additionally, the integration of advanced materials can lead to longer lifespans. Valves made from corrosion-resistant materials handle harsh environments better. However, not all control valves are universally applicable. Some may be too sensitive for certain applications, leading to over-responses. Others might fail to provide adequate precision, impacting overall process management.

Choosing the best control valve often requires a balance between features and specific application needs. It's essential to assess system requirements thoroughly. Ultimately, careful evaluation and selection processes can prevent costly mistakes and operational inefficiencies. However, there's always room for improvement in decision-making. Adjusting criteria based on practical experiences might yield better outcomes.

Comparative Analysis of Leading Control Valve Brands and Models

Selecting the right control valve is crucial for process management. Various brands offer different functionalities. Each model varies in design and performance metrics. Features like pressure rating, size, and response time matter. It’s essential to analyze these aspects closely.

**Tip:** When evaluating control valves, prioritize your specific needs. Understand the fluid dynamics in your system. This understanding will help ensure optimal performance. Many overlook the importance of flow characteristics. A valve’s ability to handle varying flow rates impacts your process.

Not all control valves suit every application. Some may have limited adjustability. Others might struggle under extreme conditions. Evaluate the pros and cons of each model thoroughly. Consider factors such as maintenance needs and installation challenges. Skipping this step can lead to inefficiencies down the line.

**Tip:** Regularly review your valve performance. Are they meeting expectations? This practice can reveal hidden issues and improve reliability. Remember, even the most expensive valves can fail without proper oversight. Stay proactive to avoid unexpected downtimes.

Performance Comparison of Control Valves

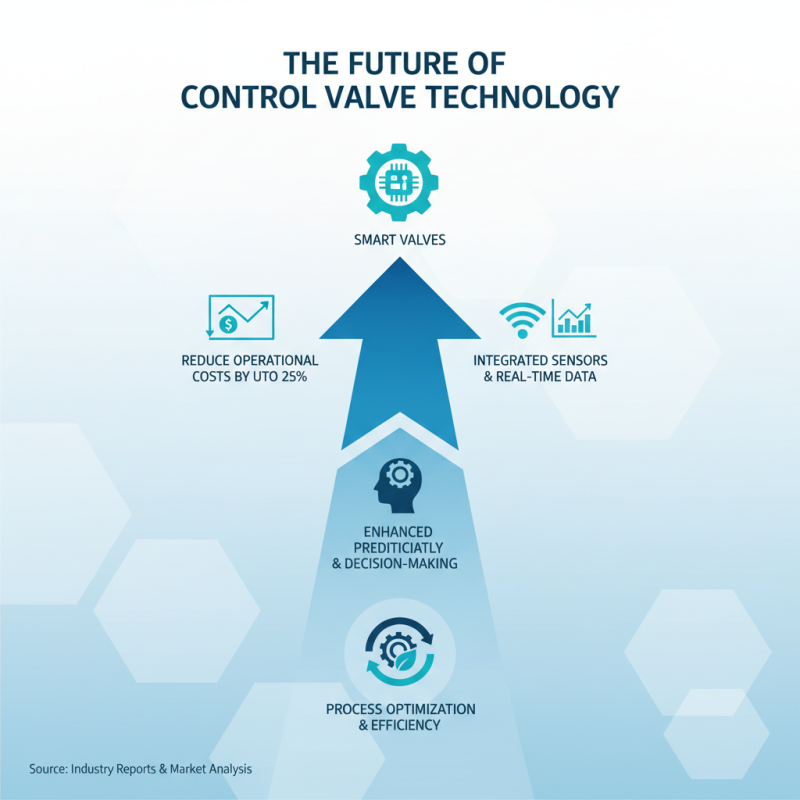

Future Trends in Control Valve Technology and Process Optimization

The future of control valve technology is evolving rapidly. Industry reports indicate that advancements in smart technologies are driving efficiencies. For instance, a recent market analysis shows that smart valves can reduce operational costs by up to 25%. These advancements include integrated sensors that provide real-time data. Such features enhance the predictability of system behavior, enabling better decision-making for process optimization.

Moreover, the Internet of Things (IoT) is significantly influencing control valve design. By connecting valves to cloud platforms, operators can monitor performance remotely. This allows for proactive maintenance, preventing unexpected downtimes. Reports indicate that companies leveraging IoT-based solutions have seen a 30% increase in uptime. Yet, challenges remain. Many organizations struggle with legacy systems that cannot easily integrate with new technologies. Transitioning to new systems can be complex and costly.

There is also a growing emphasis on sustainability in valve design. The industry is increasingly focusing on eco-friendly materials and energy-efficient designs. However, not all companies prioritize sustainable practices, raising a big question about accountability. As sustainability becomes a key factor, those lagging behind risk obsolescence in a competitive market. Adapting to these trends is crucial for future success and improved process management.

Related Posts

-

Understanding the Importance of Control Valves in Modern Industrial Applications

-

How to Choose the Right Control Valve for Your Industrial Applications

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

Why a Safety Valve is Essential for Industrial Equipment in 2026

-

How to Choose the Right Safety Valve for Your Application?

-

2026 How to Choose the Right Solenoid Valve for Your Application?