Best Cryogenic Check Valves for Essential Applications in Cold Environments

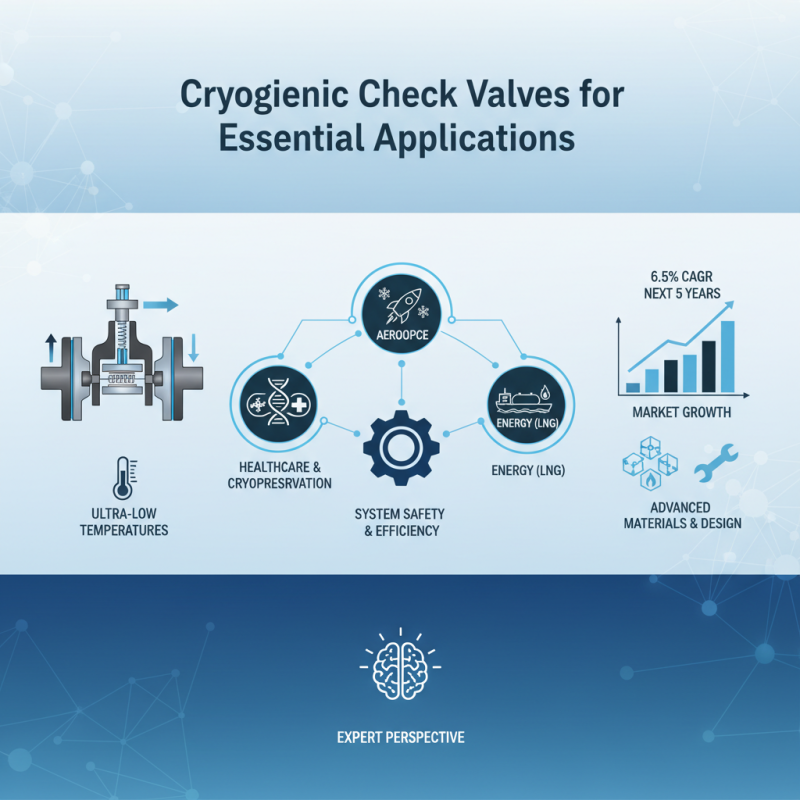

In the field of cryogenic engineering, the significance of reliable components cannot be overstated, particularly when it comes to cryogenic check valves. These valves play a crucial role in preventing backflow in pipelines carrying gases and liquids at ultra-low temperatures, ensuring system safety and efficiency. According to a recent report by the International Journal of Mechanical Engineering, the demand for cryogenic check valves is projected to grow at a CAGR of 6.5% over the next five years, driven by advancements in the aerospace, healthcare, and energy sectors.

Industry expert Dr. Emily Carter, a recognized authority on cryogenic systems, emphasizes the importance of selecting the right materials and designs for these valves, stating, "The reliability of a cryogenic check valve is paramount; even minor failures can compromise entire systems in environments where every degree matters." This perspective highlights the demands placed on engineers and designers to ensure that cryogenic check valves can withstand extreme conditions while maintaining optimal performance.

As applications in cold environments expand—from liquefied natural gas (LNG) transportation to cryopreservation technologies—the need for high-quality cryogenic check valves becomes increasingly critical. A thorough understanding of their operational parameters, material components, and recent innovations in valve technology will aid industry professionals in selecting the best solutions for essential applications.

Overview of Cryogenic Check Valves and Their Importance

Cryogenic check valves are vital components used across various industries that require the handling of supercooled fluids, such as liquefied natural gas (LNG) and liquid nitrogen. These valves are designed to prevent backflow, ensuring that the systems operate efficiently and safely under extreme temperatures. According to a report by Markets and Markets, the cryogenic valve market is projected to reach USD 5.85 billion by 2026, driven by the increasing demand for renewable energy and the expansion of LNG infrastructure. The reliability of cryogenic check valves ensures not only optimal performance but also minimizes the risks of leaks and potential hazards in equipment and pipelines.

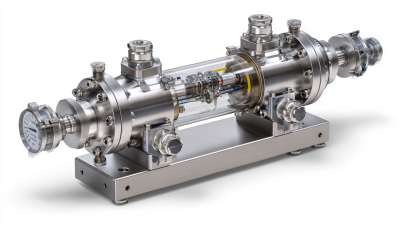

In cold environments, the performance of these valves is critical. Traditional valve designs often struggle to function properly at cryogenic temperatures, leading to potential operational failures. The unique engineering of modern cryogenic check valves, which often includes features such as enhanced sealing materials and specialized body designs, allows them to withstand temperatures as low as -196°C. According to the Cryogenic Society of America, maintaining system integrity under such conditions can prevent catastrophic failures, thus emphasizing the importance of investing in high-quality cryogenic check valves for reliable operations. These advancements ultimately contribute to the safety and efficiency of essential applications within the energy sector, aerospace, and other cold temperature operations.

Key Features to Consider in Cryogenic Check Valves

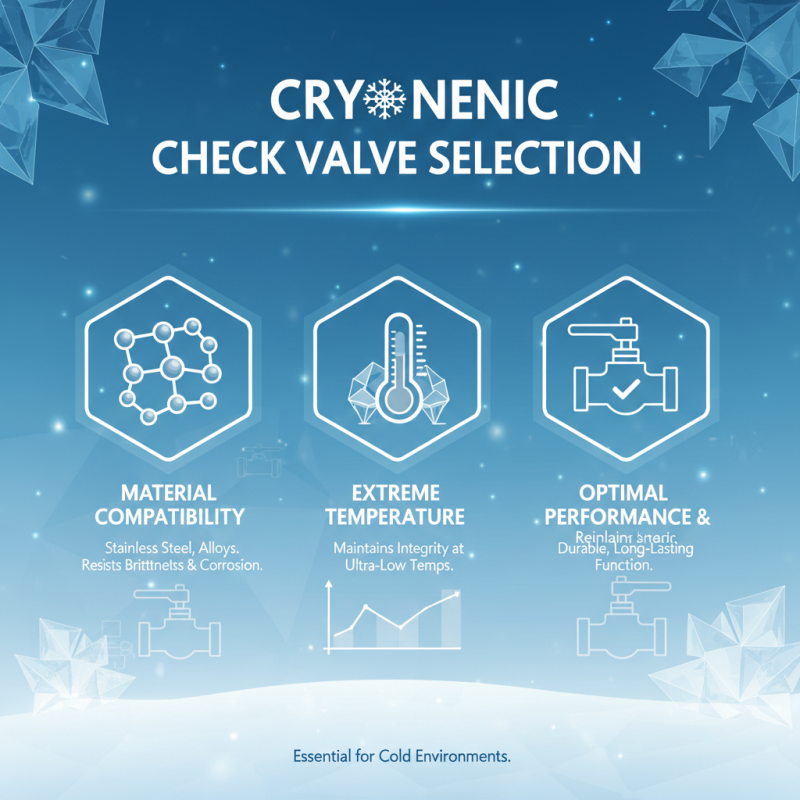

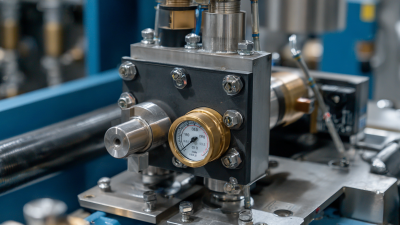

When selecting cryogenic check valves for essential applications in cold environments, several key features must be considered to ensure optimal performance and reliability. First and foremost, material compatibility is crucial. Cryogenic conditions require materials that can withstand extreme low temperatures without becoming brittle or compromising structural integrity. Stainless steel and certain alloys are commonly preferred for their durability and resistance to corrosion, which is vital in maintaining valve functionality over time.

Another important factor is the valve design itself. A valve that is specifically engineered for cryogenic applications tends to have a streamlined flow path to minimize turbulence and pressure drop. Additionally, the sealing mechanism should be robust enough to handle the thermal stresses associated with rapid temperature changes. Features like self-cleaning designs or low-maintenance seals can greatly enhance the longevity and efficiency of the valve, reducing the need for frequent replacements or repairs.

Moreover, it is essential to consider the operational aspects such as the valve's response time and opening pressure. A quick-response check valve can prevent backflow efficiently, safeguarding critical systems that rely on continuous flow. Furthermore, the ability to operate under varying pressure ranges ensures that the valve remains effective across different operational scenarios. These features collectively contribute to the overall reliability and effectiveness of cryogenic check valves in demanding applications.

Top Brands and Products for Cryogenic Check Valves

When selecting cryogenic check valves for essential applications in cold environments,

it's crucial to consider the reliability and performance of various products. These valves are designed to operate efficiently

at extremely low temperatures, preventing backflow in systems that handle liquefied gases. Leading manufacturers innovate continually,

focusing on materials and designs that withstand the challenges posed by cryogenic conditions while ensuring

durability and safety.

Top brands emphasize the importance of quality in their product offerings, introducing valves that utilize advanced sealing technologies

and precision engineering. Many cryogenic check valves feature specialized designs, such as swing and spring-loaded configurations,

to accommodate diverse operational requirements. Furthermore, these products often undergo rigorous testing to meet industry standards,

ensuring they function optimally in the coldest environments. By investing in

well-reviewed and tested options, users can enhance system reliability

and performance in sectors like aerospace, liquefied natural gas, and medical applications.

Applications and Industries Utilizing Cryogenic Check Valves

Cryogenic check valves play a crucial role in various industries that operate in extremely low-temperature environments. One of the primary applications of these valves is in the aerospace sector, where they are utilized to manage cryogenic fuels such as liquid oxygen and hydrogen. These fuels require precise control to ensure safe handling and efficient propulsion systems in spacecraft. The ability to prevent backflow in these demanding conditions is essential, as it contributes to the overall safety and performance of rocket systems.

Another significant application of cryogenic check valves is in the medical and pharmaceutical industries, particularly in the storage and transport of cryogenic gases and liquids. For instance, these valves are used in systems that handle liquid nitrogen, which is vital for preserving biological samples and maintaining the efficacy of certain medications. The integrity of these systems is paramount, as any leakage could compromise the samples or lead to adverse effects in manufacturing processes. As technology advances, the demand for reliable cryogenic check valves continues to grow, highlighting their importance across various critical applications.

Best Cryogenic Check Valves for Essential Applications in Cold Environments

| Application | Industry | Temperature Range (°C) | Material | Pressure Rating |

|---|---|---|---|---|

| Cryogenic Liquefaction | Gas & Oil | -196 to 0 | Stainless Steel | 150 psi |

| LNG Transfer | Energy | -162 to -30 | Cryogenically Treated Steel | 300 psi |

| Helium Recovery | Aerospace | -270 to -50 | Inconel | 200 psi |

| Cryogenic Storage | Medical | -196 to -80 | Brass | 100 psi |

| Cryogenic Cooling Systems | Semiconductor | -150 to -60 | Aluminum | 250 psi |

Maintenance and Best Practices for Cryogenic Check Valves

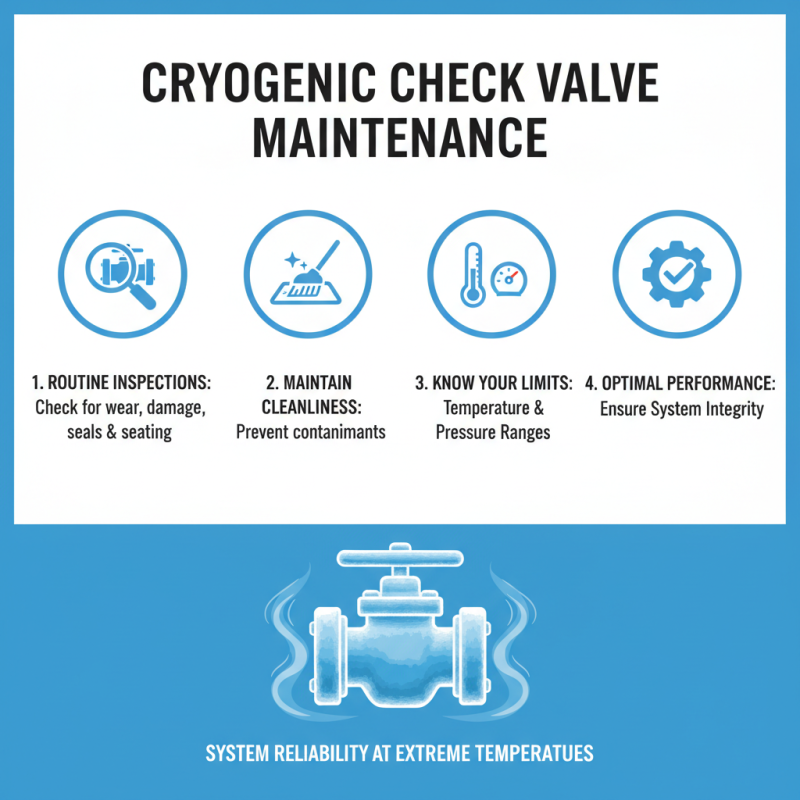

Cryogenic check valves play a crucial role in maintaining the integrity of systems operating in extremely low-temperature environments. To ensure optimal performance, routine maintenance is essential. Regular inspections should focus on checking for signs of wear or damage, particularly in seals and seating surfaces. Contaminants can compromise the valve's function, so keeping the surrounding area clean is vital. Additionally, understanding the specific temperature ranges and pressure limits of your valves can help prevent operational failures.

**Tips: Ensure you perform regular visual inspections and keep a maintenance log. This practice helps in identifying patterns or recurring issues that need attention.**

In terms of best practices, one should always ensure that the valves are installed in accordance with the manufacturer’s guidelines, paying particular attention to orientation and sealing methods. Using proper tools during installation can prevent accidental damage. Consider implementing a proactive maintenance schedule based on the valve’s usage and environmental conditions. This not only extends the lifespan of the valve but also enhances reliability during critical operations.

**Tips: When replacing seals or other parts, opt for components that are rated for cryogenic applications to maintain performance standards.**

Related Posts

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

-

How to Choose the Right Cryogenic Valves for Your Applications

-

Top 10 Hydrogen Valves for Optimal Performance and Safety in Applications

-

How to Choose the Right Air Valve for Your Pneumatic System Needs

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data