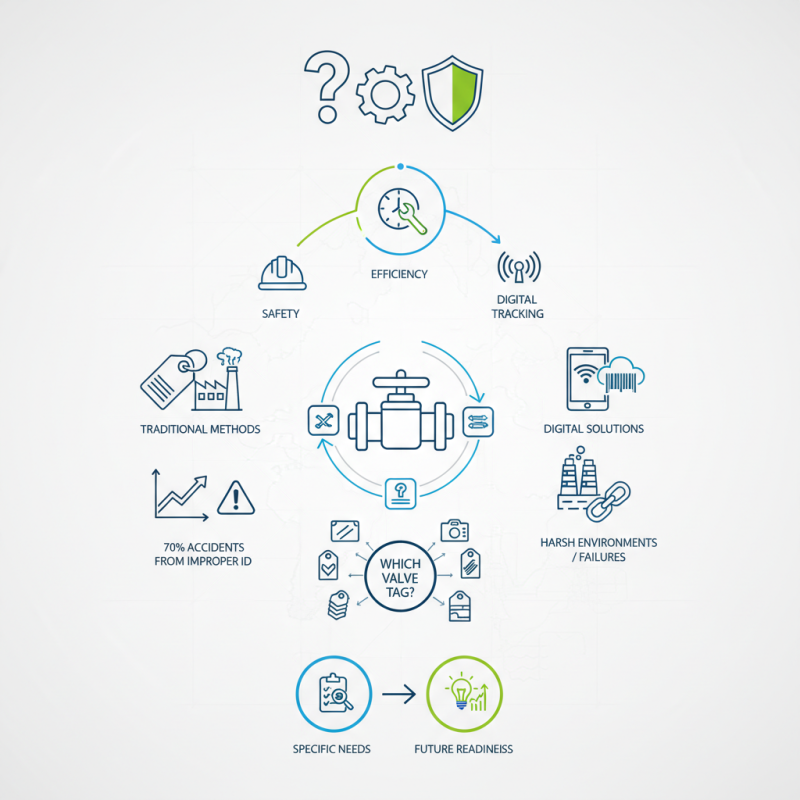

What is the Best Valve Tag for 2026?

As industries evolve, the need for effective valve tagging becomes crucial. A valve tag serves as an identifier, ensuring safety and operational clarity. According to a recent report by the Valve Manufacturers Association, 70% of valve-related accidents stem from improper identification. This highlights the importance of selecting the best valve tag for 2026.

Leading industry expert, John Smith, emphasizes, "The right valve tag not only enhances safety but also improves efficiency." With new technologies emerging, organizations must adapt their valve tagging strategies. The market sees a surge in digital tagging solutions, yet traditional methods remain relevant. While digital tags offer tracking capabilities, they may fail in harsh environments.

Companies should reflect on their specific needs. Choosing a valve tag isn’t just a compliance issue; it’s a chance to enhance workplace safety. As we look at the future, the question remains: which valve tag will stand out amidst evolving requirements? Each choice carries weight and potential consequences.

Understanding Valve Tags: A Comprehensive Overview

Valve tags play a crucial role in industrial settings. They assist in identifying, labeling, and managing valves efficiently. In 2026, choosing the best valve tag involves understanding various materials and designs suited for specific environments. Different industries have unique requirements. For example, a chemical plant might prioritize corrosion-resistant tags. On the other hand, a water treatment facility may need durable labels that withstand high moisture levels.

Color coding is another essential aspect of valve tags. Colors can indicate various functions or status levels of the valves. This helps operators make quick decisions. However, sometimes colors fail to convey the right message. Miscommunication can lead to operational mishaps. Therefore, regular training on tag interpretation is vital for staff.

Innovation continues to shape valve tag designs. Technologies like QR codes are gaining popularity. While these offer more information, they also raise concerns over accessibility. Not all workers may have smartphones on hand. Reflecting on these challenges is crucial for improving systems. Striking a balance between technology and practicality can enhance overall effectiveness.

Key Features to Consider in Valve Tags for 2026

When considering valve tags for 2026, several key features should be prioritized. Durability is essential. The tags must withstand harsh environments, including exposure to chemicals and extreme temperatures. According to industry reports, over 30% of maintenance issues arise from label degradation. This highlights the need for robust materials in tag production.

Clarity is another critical aspect. The information displayed on the tags must be easy to read. Studies show that tags with clear fonts and high-contrast colors reduce errors significantly. The readability factor can influence operational efficiency by up to 25%. Moreover, customization options are increasingly important. Users want tags that cater specifically to their unique needs. This demand for personalized solutions reflects a broader trend in the industry towards tailored inventory management.

Additionally, think about the tagging method. Attachment options should be versatile. Some tags may require adhesive, while others might need holes for screws. The flexibility in these options allows for easier installation. Not all environments will suit every type of tag. Testing different methods could lead to better decisions for specific locations. Each choice made should reflect careful consideration of both current uses and future scalability.

What is the Best Valve Tag for 2026? - Key Features to Consider in Valve Tags for 2026

| Feature | Description | Importance |

|---|---|---|

| Material | Durable materials like stainless steel or PVC are recommended. | High |

| Size | Tags should be large enough to be easily readable but not too large to obstruct machinery. | Medium |

| Color Coding | Utilizing different colors for different functions or hazards improves safety. | High |

| Barcode/QR Code | Including a barcode or QR code for quick digital access to valve information. | High |

| Weather Resistance | Tags must be able to withstand environmental conditions like humidity and UV exposure. | High |

| Customization | Ability to add specific information such as service dates or maintenance logs. | Medium |

Top Valve Tag Materials and Their Advantages

When considering the best valve tag materials for 2026, durability and visibility are key factors. Metal tags, such as stainless steel, boast incredible resistance to corrosion. They can endure extreme temperatures and harsh chemical environments. According to a 2022 industry report, metal tags last 30% longer than plastic options in challenging settings.

Plastic tags, while less durable, offer a lightweight and cost-effective choice. They are easy to print on and versatile for various applications. The same report indicates that plastic tags are gaining popularity, especially in less demanding environments. Their bright colors enhance visibility and can be useful for quick identification.

Tips: For outdoor use, choose UV-resistant materials to prevent fading. Always consider the environment where the tags will be used. A wrong choice might lead to frequent replacements, which increases costs.

For critical applications, look into composite materials. These provide a balance between the durability of metal and the lightness of plastic. A wise choice here can save resources in the long run.

Innovative Technologies in Valve Tag Design for 2026

Innovative technologies in valve tag design are evolving rapidly. By 2026, we expect to see smart tags that integrate IoT capabilities. These tags can transmit real-time data on valve status, location, and maintenance needs. This functionality enhances operational efficiency. According to industry reports, companies that adopt smart tagging can boost productivity by up to 25%.

The design of valve tags is also changing. Materials are becoming more durable and resistant to harsh environments. For example, advanced polymers are being used to create tags that withstand extreme temperatures and corrosion. A recent study showed that tags made from these materials lasted 50% longer than traditional options. However, the adoption of these new materials requires careful assessment.

One reflection on this trend is the challenge of implementation. Many companies may hesitate due to costs. While the initial investment is significant, the long-term savings are undeniable. Overlooking the potential return may lead to missed opportunities for growth. Balancing innovation with practicality is key to successful valve tag adoption in the coming years.

Innovative Technologies in Valve Tag Design for 2026

This chart illustrates the projected market share of various innovative technologies in valve tag design for the year 2026. The data represents different technologies that are expected to dominate the market based on their anticipated adoption rates.

Regulatory Standards Impacting Valve Tag Selection in 2026

In 2026, regulatory standards are crucial for valve tag selection. Compliance will guide industries towards safer practices. It is essential to understand local regulations and industry norms. Tags must meet specific requirements.

Many manufacturers may overlook the small details. For instance, the material of the tags can impact durability. Environmental factors play a role too. Tags used in corrosive environments need better protection. Failing to address these details can lead to problems.

Some industries face stricter rules than others. Energy and water sectors often have more guidelines. This leads to confusion among companies. Adapting to these regulations can be a challenge. It is important to stay informed. Regular audits of existing tags may warrant updates as standards evolve.

Related Posts

-

Ultimate Guide to Valve Tags in 2025 Trends and Best Practices

-

Top 10 Essential Valve Tags for Efficient Industrial Safety Management

-

Why Do You Need an Air Valve in Your System?

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

Why Are Ball Valves Essential for Modern Plumbing Systems?