Top Tips for Choosing and Maintaining Stainless Steel Solenoid Valves

When selecting components for fluid control systems, the **stainless steel solenoid valve** stands out as a pivotal choice due to its durability and resistance to corrosion. These valves are ideal for a variety of applications, ranging from industrial machinery to water treatment facilities. Understanding the key factors in selecting the right stainless steel solenoid valve can significantly enhance the performance and reliability of your system.

In this guide, we will delve into essential tips for choosing the appropriate stainless steel solenoid valve, ensuring that it meets your operational needs and withstands environmental challenges. Additionally, we will address maintenance practices that can prolong the lifespan and efficiency of these valves. By adhering to these guidelines, users can optimize the functionality of their fluid control systems and minimize the likelihood of malfunctions, resulting in safer and more efficient operations.

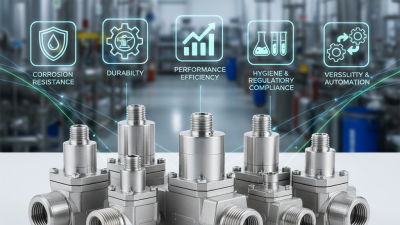

Understanding Stainless Steel Solenoid Valves: Features and Benefits

Stainless steel solenoid valves are essential components in various industrial applications due to their robust construction and reliability in demanding environments. The choice of stainless steel as a material offers significant advantages, particularly resistance to corrosion and the ability to withstand high temperatures. According to a report by MarketsandMarkets, the global solenoid valve market is projected to reach $5.2 billion by 2026, highlighting the increasing demand for durable and efficient solutions across industries such as water treatment, oil and gas, and manufacturing.

One of the most critical features of stainless steel solenoid valves is their excellent sealing capacity, which minimizes leakage and improves overall system efficiency. These valves typically maintain optimal performance even under extreme conditions, making them suitable for aggressive fluids and gases. A study published by the International Journal of Industrial Automation and Control outlines that the use of stainless steel solenoid valves can enhance energy efficiency by up to 20% in fluid control systems, showcasing their role in promoting cost-effective operations.

Moreover, the longevity of stainless steel solenoid valves is noteworthy, as they often exceed the lifespan of conventional materials, leading to reduced maintenance costs over time. The right selection and ongoing maintenance of these valves can optimize their performance, with regular checks on coil integrity and actuator response time recommended for ensuring reliability. With their combination of strength, efficiency, and long-term cost savings, stainless steel solenoid valves clearly represent a smart investment for sectors requiring consistent and dependable flow control solutions.

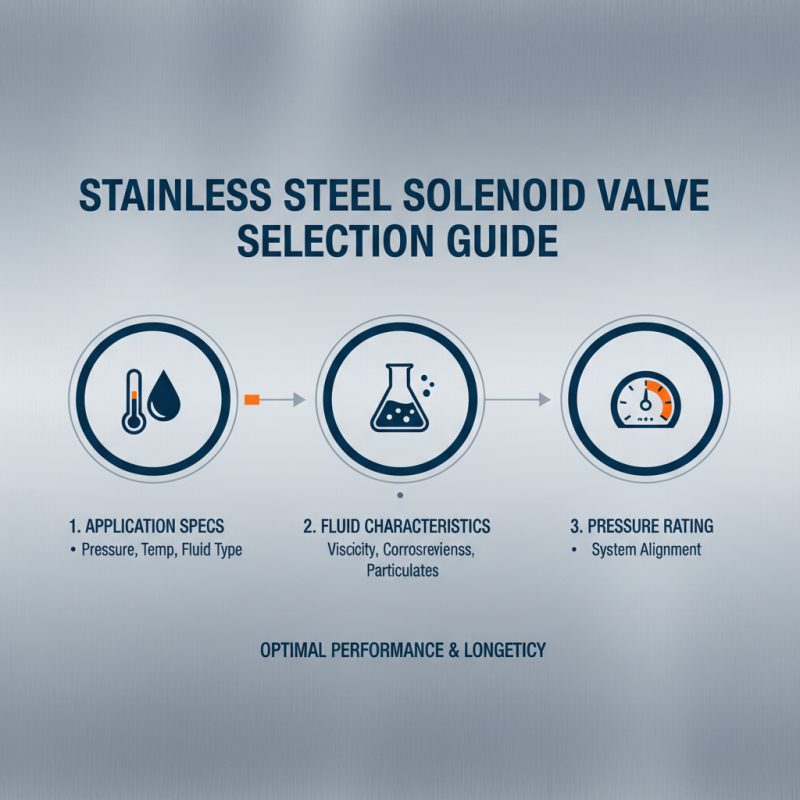

Key Factors to Consider When Selecting a Stainless Steel Solenoid Valve

When selecting a stainless steel solenoid valve, several key factors must be taken into account to ensure optimal performance and longevity. First, consider the specifications of the application, such as pressure, temperature, and the type of fluid being controlled. Understanding the fluid characteristics, including viscosity, corrosiveness, and presence of particulates, is essential, as these factors can significantly impact the valve's operation and lifespan. Additionally, ensure that the valve's pressure rating aligns with the system requirements to avoid potential failures.

Another important consideration is the valve's design and construction quality. Stainless steel solenoid valves should be made from high-quality materials that can withstand environmental and operational stresses. Features such as leakage prevention, response time, and compatibility with automation systems should be thoroughly evaluated. Furthermore, look for valves with easy maintenance requirements and service accessibility, which can reduce downtime and improve overall efficiency. Proper selection based on these critical factors will lead to better system performance and lower maintenance costs in the long run.

Best Practices for Installing Stainless Steel Solenoid Valves Properly

When installing stainless steel solenoid valves, proper positioning and secure mounting are crucial for optimal performance. Begin by selecting an installation location that is easily accessible for maintenance while ensuring it is free from corrosion-causing elements and excessive vibrations. The orientation of the valve should align with its specified operating direction marked on the body; failure to do so may lead to malfunction. It is also important to provide adequate space around the valve to facilitate heat dissipation and to allow for any necessary repairs or adjustments.

Next, ensure that the piping connected to the solenoid valve is properly aligned and supported to prevent unnecessary stress on the valve. Use suitable sealing materials when connecting the valve to avoid leaks. Avoid over-tightening fittings, as this can cause damage to the valve threads and lead to future leaks. After installation, conduct a thorough inspection for leaks and ensure that the valve operates smoothly with the input control signals. Regularly check the solenoid for signs of wear or malfunction to maintain efficiency and extend the lifespan of the valve.

Performance Comparison of Stainless Steel Solenoid Valves

This chart compares the performance metrics of two different stainless steel solenoid valves across several important dimensions, including response time, leak rate, maximum pressure, and operating temperature. This information can assist in making informed decisions when selecting and maintaining solenoid valves.

Routine Maintenance Tips for Prolonging the Life of Solenoid Valves

Routine maintenance of stainless steel solenoid valves is essential to ensure their longevity and optimal performance in various industrial applications. According to a recent industry report by the National Electrical Manufacturers Association (NEMA), proper upkeep can significantly reduce operational downtime and extend the lifespan of solenoid valves by up to 50%. Regular inspections should include checking for leaks, ensuring proper functioning of the coil, and verifying that the valve body is free from corrosion or debris that may impede flow.

Additionally, maintaining an appropriate environment for solenoid valves greatly influences their durability. Factors such as temperature fluctuations, humidity, and exposure to corrosive substances should be monitored. Implementing routine cleaning procedures, such as flushing the valve with suitable fluids and lubricating moving parts, can further enhance performance. A study published in the Journal of Mechanical Engineering highlights that valves subjected to consistent maintenance showed a dramatic reduction in failures, with only 5% of regularly maintained valves experiencing issues compared to 25% in those left unattended.

Overall, adhering to a structured maintenance routine not only preserves the functionality of stainless steel solenoid valves but also contributes to the efficiency of the entire system they operate within. By prioritizing these practices, industries can mitigate risks and ensure seamless operations in demanding environments.

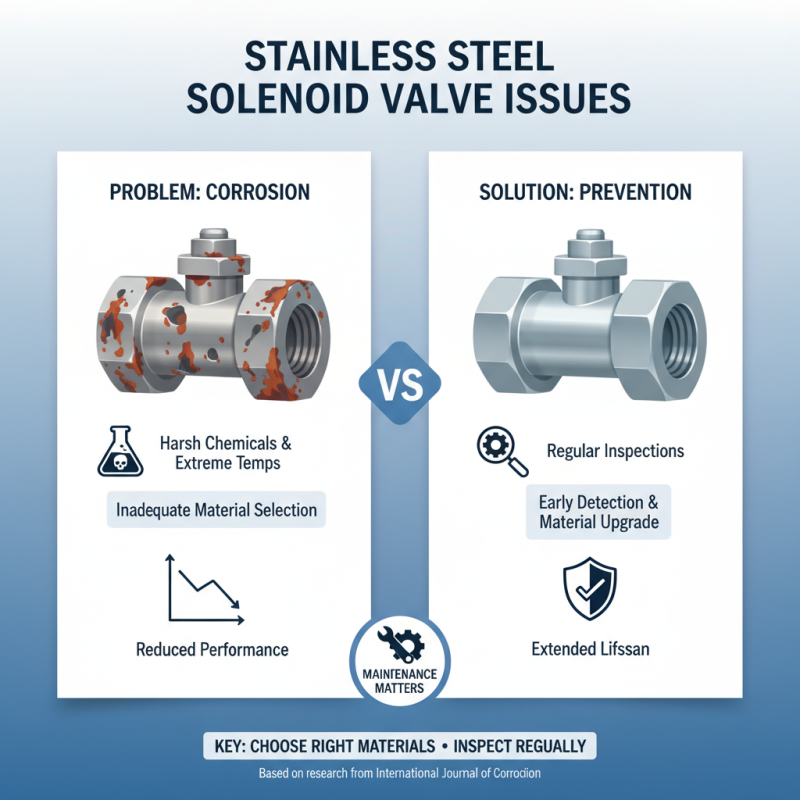

Common Issues and Troubleshooting Techniques for Stainless Steel Valves

When dealing with stainless steel solenoid valves, common issues can arise that hinder performance. One frequent problem is corrosion, which, despite the valves being made from stainless steel, can occur due to inadequate material selection for specific environments. Research from the International Journal of Corrosion indicates that even high-grade stainless steel can corrode when exposed to harsh chemicals or extreme temperatures. Regular inspections are crucial to identify early signs of corrosion and address them before they lead to valve failure.

Another common issue is the accumulation of debris or scale inside the valve, which can obstruct flow and affect functionality. Industry data suggests that routine maintenance, including cleaning and periodic replacing of seals and internal components, can significantly extend the life of solenoid valves. Implementing a preventive maintenance schedule can save industries approximately 30% in potential downtime and repair costs, according to the American Society of Mechanical Engineers.

To maintain optimal operation, consider the following tips: always choose the correct valve for the specific application, as incompatibility can lead to premature failure; promptly address any leaks or unusual sounds, as they can signal imminent problems; and ensure all installation aligns with manufacturer specifications to prevent operational issues. By adhering to these practices, businesses can improve reliability and reduce maintenance costs associated with stainless steel solenoid valves.

Related Posts

-

Top 5 Benefits of Using Stainless Steel Solenoid Valves in Industry

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

Ultimate Guide to Valve Tags in 2025 Trends and Best Practices

-

Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

How to Choose the Right Control Valve for Your Industrial Applications