How to Choose the Right Cryogenic Valves for Your Applications

Choosing the right cryogenic valves for your applications is crucial for ensuring system efficiency, safety, and performance. As industries increasingly utilize cryogenic technologies in fields such as liquefied natural gas (LNG), aerospace, and biomedical sectors, the demand for reliable cryogenic valves has soared. These specialized valves are designed to control the flow of fluids at very low temperatures, and selecting the appropriate type can greatly influence operational success.

When choosing cryogenic valves, it is essential to consider various key factors, including the specific application requirements, the properties of the media being transported, and the operational environment. Different design features, such as valve materials, sealing mechanisms, and actuation types, play a significant role in the performance and longevity of cryogenic valves. It is important to thoroughly assess these factors to avoid costly failures or malfunctions in your systems.

Ultimately, understanding the unique characteristics and applications of cryogenic valves will empower you to make informed decisions that enhance system reliability and operational efficiency. Whether you're involved in the design, installation, or maintenance of cryogenic systems, an informed approach to valve selection is essential for achieving optimal performance and safety standards.

Understanding Cryogenic Valves and Their Importance in Industry

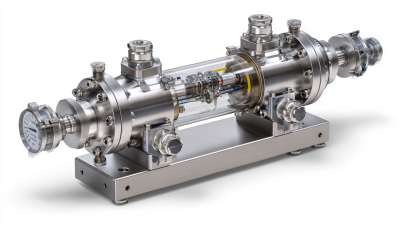

Cryogenic valves are essential components in various industrial applications where gases and liquids are maintained at extremely low temperatures, typically below -150°C. Understanding cryogenic valves and their importance is crucial for anyone involved in industries such as liquefied natural gas (LNG), aerospace, and medical technology. These valves control the flow of cryogenic fluids, ensuring safety and efficiency during operations. Their design and material selection must withstand the challenges posed by low-temperature environments, which can lead to brittleness and failure if not properly addressed.

When selecting cryogenic valves, it’s critical to consider both the materials used and the specific application requirements. Materials such as stainless steel or exotic alloys are often preferred due to their durability and resistance to thermal shocks. Additionally, ensure that the valve type you choose aligns with your process needs—gate valves, globe valves, and ball valves each have distinct characteristics suitable for different applications.

Tips: Always verify the temperature and pressure ratings of the valves to prevent operational failures. It is also advisable to consult with industry experts or engineers who have experience in cryogenic applications to ensure the right choice of valves. Regular maintenance and inspections are vital to extend the lifespan of cryogenic valves and maintain safety standards in your operation.

Key Factors to Consider When Selecting Cryogenic Valves

When selecting cryogenic valves for specific applications, it is crucial to consider several key factors to ensure optimal performance and safety. One of the primary considerations is the valve material. Given the extreme temperatures typical in cryogenic environments, materials such as stainless steel or specific alloys might be necessary to prevent brittleness and maintain structural integrity. A study by the International Cryogenic Engineering Committee emphasizes that using improper materials can lead to catastrophic failures, underlining the importance of selecting compatible materials based on application requirements and service conditions.

Another significant aspect is the type of valve mechanism. Two popular types in cryogenic applications include globe and ball valves, each designed for different flow control scenarios. According to a report by the Cryogenic Society of America, globe valves are often favored for precise flow regulation, whereas ball valves excel in applications requiring quick shut-off capability. Assessing flow requirements and operational pressures will guide users in making an informed choice about which type of valve fits their application best.

**Tips**: Always review the cryogenic system’s specific operating conditions, including temperature and pressure fluctuations, as these factors will inform the selection of valve types and materials. Additionally, consulting with industry standards and guidelines will help ensure compliance and enhance safety measures.

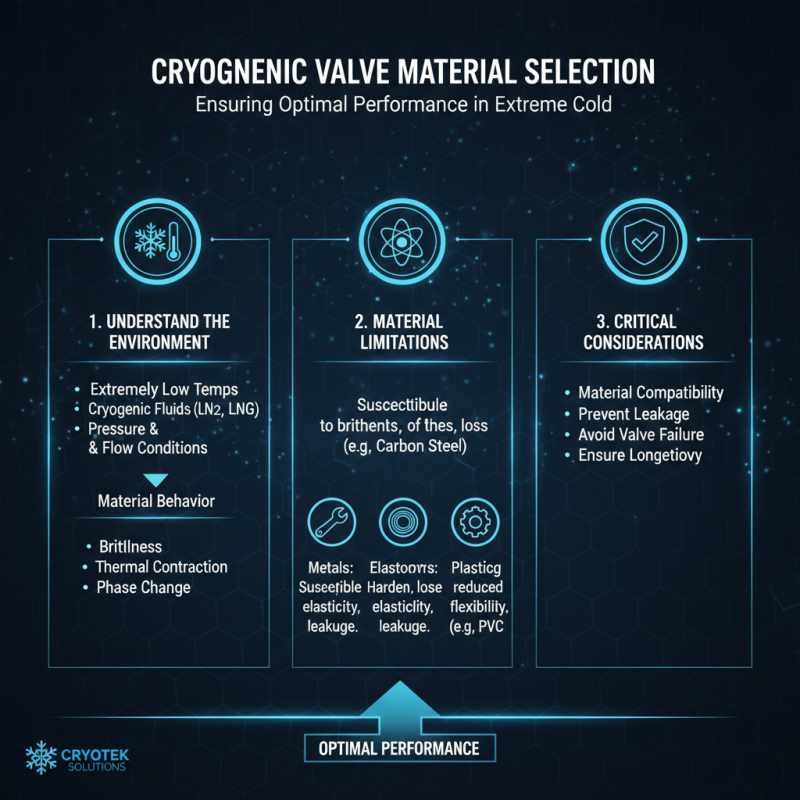

Material Compatibility: Ensuring Optimal Performance at Low Temperatures

When selecting cryogenic valves for specific applications, material compatibility is critical to ensuring optimal performance in extremely low temperatures. The selection process begins with understanding the cryogenic environment in which the valves will operate, as different materials react uniquely under such conditions. Metals, elastomers, and plastics each have their own limitations, and choosing the wrong material can lead to issues such as brittleness, leakage, or failure of the valve.

For example, stainless steel is often a preferred choice for cryogenic valves due to its excellent mechanical properties and resistance to corrosion at low temperatures. However, other materials like brass may not perform adequately as temperatures drop, leading to material degradation. Furthermore, seals and gaskets must also be carefully selected; specific elastomers are designed to maintain flexibility and resilience, ensuring a reliable seal under cryogenic conditions. In conclusion, thorough knowledge of how materials behave in low-temperature environments is essential for making informed decisions about cryogenic valves, ultimately maximizing their performance and reliability in critical applications.

Industry Standards and Certifications for Cryogenic Valve Selection

When selecting cryogenic valves for specific applications, understanding industry standards and certifications is crucial. These guidelines ensure that the valves can operate effectively under extreme low temperatures while maintaining safety and reliability. Standards such as ASTM, ASME, and API provide specifications that address material selection, design, testing, and performance characteristics essential for cryogenic environments. Compliance with these standards guarantees that the valves can withstand the challenges posed by liquefied gases and other cryogenic materials.

Moreover, certifications from recognized organizations enhance the credibility of the valve selection process. For instance, valves that are certified by entities like the American Society of Mechanical Engineers (ASME) or the American Petroleum Institute (API) signify adherence to rigorous testing and quality control procedures. These certifications often reflect the valve's durability, cryogenic performance, and overall suitability for specific industrial applications. When choosing cryogenic valves, it is vital to ensure that they not only meet the relevant industry standards but also hold the necessary certifications to provide assurance of their performance and safety in demanding situations.

How to Choose the Right Cryogenic Valves for Your Applications - Industry Standards and Certifications for Cryogenic Valve Selection

| Valve Type | Material | Temperature Range (°C) | Pressure Rating (bar) | Industry Standards | Certifications |

|---|---|---|---|---|---|

| Ball Valve | Stainless Steel | -196 to 150 | up to 40 | ASME B16.34 | ISO 9001 |

| Gate Valve | Cryogenic Bronze | -196 to 200 | up to 50 | API 600 | CE Marking |

| Globe Valve | Carbon Steel | -196 to 120 | up to 30 | BS 5352 | TUV |

| Check Valve | Ductile Iron | -196 to 180 | up to 25 | API 594 | ABS Approval |

Maintenance and Lifespan: Maximizing Efficiency in Cryogenic Applications

When it comes to cryogenic applications, the maintenance and lifespan of cryogenic valves play a critical role in ensuring operational efficiency and safety. These valves are subjected to extreme temperatures and pressures, necessitating regular inspection and preventive measures to avoid failures that could lead to costly downtimes. A comprehensive maintenance schedule should include routine checks for leaks, proper lubrication of moving parts, and the examination of seals and gaskets to prevent material degradation over time. Special attention should be given to the valve's actuation mechanism, which can be adversely affected by the operational environment.

To maximize the lifespan of cryogenic valves, it’s essential to consider the material compatibility with cryogenic fluids and the specific application requirements. Utilizing valves that are designed for low temperatures and that exhibit excellent resilience against fatigue and wear can significantly extend their operational life. Incorporating remote monitoring technologies can also enhance maintenance practices by providing real-time data on valve performance, allowing for timely interventions before potential failures occur. By investing in proper maintenance and choosing the right materials, organizations can ensure that their cryogenic systems remain efficient and reliable for years to come.

Efficiency of Different Cryogenic Valve Types

This chart illustrates the typical efficiency percentages of various cryogenic valve types used in applications. Understanding these efficiencies can help in selecting the appropriate valve for maximizing performance in cryogenic systems.

Related Posts

-

Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

How to Choose the Right Air Valve for Your Pneumatic System Needs

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025