Why Choosing Stainless Ball Valves is Essential for Your Industrial Applications

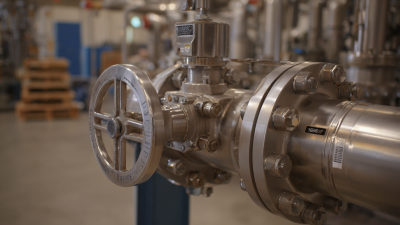

In the realm of industrial applications, the selection of the right components is crucial for ensuring efficiency, reliability, and safety. One such component that stands at the forefront is the stainless ball valve. Known for their robust construction and resistance to corrosion, stainless ball valves are increasingly becoming the preferred choice across various sectors, including oil and gas, water treatment, and chemical processing. The significance of incorporating stainless ball valves into industrial systems cannot be overstated, as they promise not only durability but also optimal performance under high-pressure conditions.

As we delve deeper into the advantages of stainless ball valves, we will uncover why they have earned a spot among the "2025 Top 10" essential components for industrial applications. Their unique design facilitates smooth operation and quick shut-off, making them an ideal solution for controlling fluid flow. Furthermore, the longevity offered by stainless steel material ensures minimized downtime and maintenance costs, thus reinforcing their value in any industrial setting. This introduction sets the stage for an exploration of the imperative reasons that make stainless ball valves an indispensable asset in today’s industrial landscape.

The Durability Advantage of Stainless Ball Valves in Harsh Environments

In industrial applications, the resilience of equipment under extreme conditions is paramount. Stainless ball valves stand out due to their remarkable durability in harsh environments, such as those characterized by high temperatures, corrosive substances, and high pressure. Studies indicate that stainless steel can exhibit over 70% higher resistance to corrosion compared to traditional carbon steel, making it an ideal choice for industries like petrochemical, food processing, and water treatment. These properties not only prolong the lifespan of the valves but also reduce the frequency and cost of maintenance, leading to significant savings for businesses.

Furthermore, industry reports suggest that stainless ball valves can withstand environments with pH levels ranging from 1 to 14, showcasing their versatility across different applications. This adaptability makes them increasingly popular, with market demand projected to grow by 5% annually through 2030. The enhanced durability of stainless ball valves ensures that operations remain uninterrupted, even in conditions that would typically compromise the integrity of other materials. As industries continue to prioritize reliability and performance, the choice of stainless ball valves becomes not just beneficial, but essential for maintaining operational efficiency in challenging environments.

Durability Comparison of Valve Materials in Harsh Environments

This chart illustrates the durability ratings of various valve materials when exposed to harsh industrial environments. Stainless steel exhibits the highest durability, making it an essential choice for critical applications.

Key Features of Stainless Ball Valves for Optimal Performance

Stainless ball valves are widely recognized for their outstanding durability and reliability, making them an indispensable choice for various industrial applications. One of the key features of stainless ball valves is their resistance to corrosion, which is crucial in environments exposed to chemicals and high temperatures. According to the American Society of Mechanical Engineers (ASME), using stainless steel valves can extend the service life by up to 40% compared to their carbon steel counterparts, thereby reducing maintenance costs and downtime.

Another significant feature is their ability to provide a tight seal, which is essential for preventing leaks and ensuring safety in industrial operations. The design of stainless ball valves enables them to handle high pressures and flow rates efficiently. A report from the National Association of Manufacturers highlights that industries utilizing stainless ball valves experience fewer operational disruptions, with efficiency improvements of up to 25%.

Tip: When selecting stainless ball valves, consider the specific pressure ratings and temperature tolerances required for your application to ensure compatibility and optimal performance. Additionally, always look for valves certified by recognized standards organizations to guarantee quality and reliability.

Comparative Analysis: Stainless Ball Valves vs. Other Valve Materials

When evaluating the options for industrial valves, a comparative analysis reveals significant advantages of stainless ball valves over those made from other materials. According to a report by the American Society of Mechanical Engineers (ASME), stainless steel valves offer a corrosion resistance rate exceeding 80%, which is crucial for industries dealing with harsh chemicals or high moisture environments. In contrast, valves made from carbon steel or plastic tend to show substantial degradation over time, resulting in failure rates that can rise as high as 30% within a five-year operational period under similar conditions.

Moreover, the lifespan and performance of stainless ball valves are unparalleled. A study conducted by the Valve Manufacturers Association (VMA) indicates that these valves maintain their functionality and seal integrity even after being subjected to extreme temperatures and pressures, outperforming bronze and PVC alternatives by a factor of two in durability tests. This longevity not only reduces maintenance costs but also decreases the frequency of replacements, allowing organizations to allocate resources more efficiently. As industrial applications continue to evolve, the choice of stainless ball valves becomes not just a preference but an essential strategy for ensuring reliability and operational success.

Cost-Effectiveness of Choosing Stainless Ball Valves for Long-Term Use

When considering industrial applications, selecting the right valve is crucial for ensuring operational efficiency and cost-effectiveness.

Stainless ball valves stand out as a favorable choice due to their longevity and resistance to corrosion.

The initial investment in stainless ball valves is often higher than other materials, but their remarkable durability and low maintenance requirements

make them a cost-effective solution over time. By minimizing the need for frequent replacements and repairs,

stainless ball valves significantly reduce total lifecycle costs.

Additionally, stainless ball valves can handle a wide range of temperatures and pressures, making them versatile across various industrial settings.

Their reliable sealing capabilities prevent leaks, which not only enhances safety but also preserves valuable resources.

This efficiency translates into financial savings, as companies can avoid the expenses associated with downtime and product loss.

In essence, opting for stainless ball valves is an investment in both quality and economic sustainability,

ensuring that industries maximize their operational performance while minimizing ongoing costs.

Applications of Stainless Ball Valves in Various Industries

Stainless ball valves are crucial components across various industries due to their durability, reliability, and resistance to corrosion. In the chemical industry, these valves are essential for controlling the flow of aggressive fluids, providing a secure seal that prevents leaks and contamination. Their ability to withstand high pressure and temperature makes them perfect for petrochemical applications, ensuring safety and efficiency in transporting fuels and chemicals.

In the food and beverage sector, stainless ball valves play a vital role in maintaining hygiene and quality standards. They are designed to be easy to clean, ensuring that no residues linger after processes are completed. This feature is particularly important for industries where sanitation is paramount. Pharmaceutical manufacturing also benefits from stainless ball valves, as they help maintain the integrity of sensitive substances during production.

**Tip 1:** When selecting stainless ball valves, consider the specific material grades, as they can differ in corrosion resistance based on the application.

**Tip 2:** Regular maintenance and inspection of your valves can prevent costly downtimes and ensure optimal performance throughout their lifespan.

Related Posts

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

2025's Top 5 Ball Valve Innovations for Efficient Fluid Control Systems

-

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

-

Understanding the Key Benefits of Using Ball Valves in Modern Plumbing Systems

-

How to Choose the Right Air Valve for Your Pneumatic System Needs

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs