Top 10 Tips for Choosing the Right Check Valve for Your Project

When embarking on a project that involves fluid control systems, selecting the right check valve is crucial to ensuring efficiency and reliability. According to John Smith, a leading expert in the check valve industry, “The right check valve can not only enhance system performance but also significantly reduce maintenance costs.” With various types and specifications available, it can be daunting to pinpoint the most suitable option for a particular application.

Choosing the right check valve involves understanding the specific needs of your project, including factors such as pressure, flow rate, and the nature of the fluid. With numerous configurations and materials to consider, project managers and engineers must equip themselves with the right knowledge to make an informed decision. This guide will provide essential tips that can aid in selecting the ideal check valve, ultimately leading to a more robust and effective system that meets operational demands. By taking the time to evaluate these considerations, you can ensure that your project not only stays on schedule but also performs optimally in the long run.

Understanding Check Valves and Their Applications

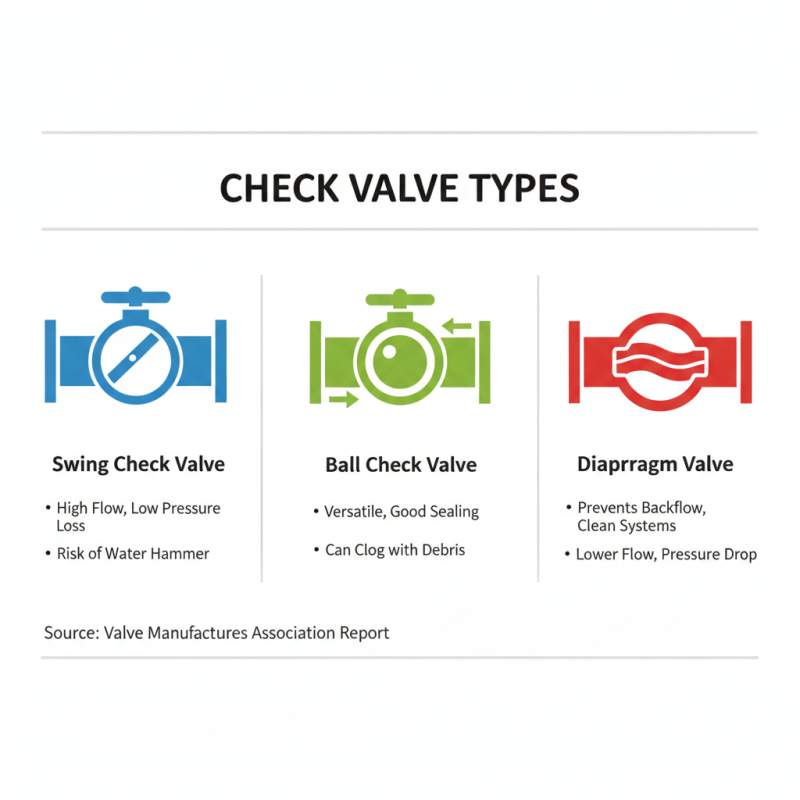

Check valves play a crucial role in various fluid systems by allowing flow in one direction while preventing backflow. They are commonly used in industries such as water management, oil and gas, and manufacturing. According to a report by Markets and Markets, the global check valve market is projected to grow from $3.2 billion in 2020 to $4.1 billion by 2025, driven by the increasing demand for advanced pipeline systems and effective liquid control measures. Understanding the different types of check valves, including swing, ball, and diaphragm, is essential for selecting the right one for your project based on application requirements.

When choosing a check valve, consider the specific application and environmental factors. For instance, a swing check valve is typically used in sewage and wastewater applications due to its ability to handle large volumes of fluids with minimal pressure loss. In contrast, a ball check valve is ideal for high-pressure systems, as it offers a tight seal and robustness. It's crucial to evaluate the material compatibility, as operational conditions can vary widely—NACE International reported that approximately 75% of corrosion failures are attributed to improper material selection.

Additionally, always pay attention to the maintenance needs and accessibility of the valve. Tip: Regular inspection of your check valves can prevent failures, as one study indicated that about 30% of unscheduled maintenance in pipelines is related to valve issues. Opting for valves with easy access for repairs can save time and reduce costs in the long run. Furthermore, consider the size and flow rate requirements to ensure optimal performance and reliability in your system.

Top 10 Check Valve Applications

Key Factors to Consider When Selecting a Check Valve

When selecting a check valve for your project, several key factors must be taken into consideration to ensure optimal performance and safety. One of the primary factors is the type of fluid that will be passing through the valve. Different fluids have varying properties, such as viscosity and temperature, which can affect the choice of materials used in the check valve's construction. It's essential to select a valve that can withstand the chemical composition and temperature range of the fluid to prevent corrosion and ensure longevity.

Flow direction and pressure ratings are also critical considerations. Understanding the specific requirements for flow direction will help determine whether a swing check valve or a lift check valve is more suitable for your application. Additionally, assessing the pressure conditions within the system is vital, as the selected check valve must be able to handle backpressure effectively. Neglecting these factors can lead to valve malfunction or system inefficiency, ultimately affecting project outcomes. Proper evaluation of these elements will guide you in making an informed decision and selecting the right check valve that meets your project's demands.

Top 10 Tips for Choosing the Right Check Valve for Your Project - Key Factors to Consider When Selecting a Check Valve

| Tip Number | Consideration | Description |

|---|---|---|

| 1 | Pressure Rating | Ensure the valve can handle the system's maximum pressure without failure. |

| 2 | Flow Direction | Select a valve that allows for the correct flow direction to prevent backflow. |

| 3 | Material Compatibility | Ensure the valve material is compatible with the fluid to avoid corrosion or contamination. |

| 4 | Size Considerations | Choose the appropriate size to fit the piping system and maintain optimal flow rates. |

| 5 | Type of Check Valve | Understand the different types (e.g., swing, lift) and select the one that suits your application. |

| 6 | Temperature Range | Check that the valve can operate effectively within the temperature limits of your application. |

| 7 | Installation Environment | Consider the environment where the valve will be installed, such as outdoor or hazardous locations. |

| 8 | Maintenance Requirements | Select a valve that requires minimal maintenance to reduce downtime and costs. |

| 9 | Cost Effectiveness | Evaluate the cost in relation to the performance and longevity of the valve. |

| 10 | Compliance and Certifications | Ensure the valve meets industry standards and certifications required for your project. |

Types of Check Valves: Pros and Cons for Your Project

When selecting a check valve for a project, understanding the different types available and their respective pros and cons is essential to ensure optimal performance and reliability. The most common types of check valves include swing check, ball check, and diaphragm check valves, each offering unique advantages that cater to specific applications. According to a report by the Valve Manufacturers Association, swing check valves are widely favored in large pipeline systems due to their ability to handle high flow volumes with minimal pressure loss. However, they can be susceptible to issues like water hammer, which could pose a risk in certain installations.

On the other hand, ball check valves are known for their compact design and effective sealing capabilities, making them ideal for applications requiring a tight closure. A study by the American Society of Mechanical Engineers indicated that ball check valves can significantly reduce the risk of backflow, which enhances system efficiency. However, they may have limitations in high-pressure scenarios compared to swing check valves. Diaphragm check valves, while less common, offer flexibility and are typically used in applications where backflow prevention is critical in intermittent fluid handling, yet their performance can be affected by fluid viscosity and temperature variations. Analyzing these options relative to your specific project requirements will ensure you choose the most suitable check valve type.

Material Selection for Check Valves Based on Fluid Compatibility

When selecting a check valve for your project, material selection is critical to ensure compatibility with the fluid being controlled. Different fluids have unique properties that can affect the performance and longevity of a valve. For instance, if you are dealing with corrosive liquids, materials like stainless steel or specialized plastics may be necessary to prevent degradation and extend service life. Conversely, for non-corrosive, neutral fluids, a variety of materials might be considered without the same level of concern.

One important tip is to understand the nature of the fluid, including its pH level, temperature, and any solid content. This knowledge will guide you toward materials that can withstand potential chemical reactions or physical wear. For example, rubber seals may perform well in some applications but could deteriorate quickly when exposed to certain solvents. Another advice is to consult compatibility charts or guidelines during your selection process, as they provide valuable insights into which materials work best with specific fluids.

Additionally, always consider the operating conditions such as pressure and temperature when choosing the valve material. High pressures might necessitate sturdier materials, while elevated temperatures could mean opting for those that maintain integrity under heat stress. By focusing on fluid compatibility and the specific demands of your application, you can make informed choices that ensure the check valve performs reliably over time.

Size and Installation Requirements for Optimal Valve Performance

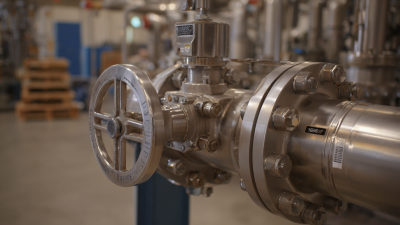

When selecting the right check valve for your project, understanding the size and installation requirements is crucial for ensuring optimal valve performance. The size of the check valve should correspond with the pipeline it will be installed in. A valve too large or too small can lead to inefficiencies, such as increased pressure loss or inadequate flow rates. Measurement of the pipe diameter and ensuring compatibility with the valve is a fundamental first step in the selection process.

Proper installation is equally important. It's essential to consider the orientation of the valve within the system. Most check valves are designed to be installed in a specific direction, and failure to adhere to this can result in malfunction or ineffective sealing. Additionally, the installation environment should be evaluated to determine if the valve requires special considerations such as seismic bracing or alignment tools.

As you assess installation points, remember these tips: ensure there’s sufficient space around the valve for maintenance and inspection, and always account for potential thermal expansion or contraction that might affect the system's pressure. Proper preparation in these areas will promote the longevity and efficiency of your valve in its intended application.

Related Posts

-

Top 10 Check Valve Types for Optimal Flow Control and Industry Applications

-

Top 10 Types of Valves: Unlocking Key Insights for Industrial Efficiency

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

How to Choose the Right Cryogenic Valves for Your Applications

-

Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs