Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

In the rapidly evolving landscape of cryogenic applications, the efficiency and reliability of components such as the cryogenic solenoid valve play a pivotal role in optimizing performance. According to a recent industry report by MarketsandMarkets, the global cryogenic valve market is projected to reach USD 2.1 billion by 2026, growing at a CAGR of 4.5%. This growth underscores the increasing demand for advanced solutions that enhance operational efficiency in numerous sectors, including aerospace, LNG production, and medical applications. Cryogenic solenoid valves are particularly crucial due to their ability to manage the flow of liquefied gases at ultra-low temperatures, ensuring safety and preventing leaks. This article will delve into the intricacies of cryogenic solenoid valves, exploring their applications and analyzing performance data to provide a comprehensive understanding of their significance in modern engineering and manufacturing processes.

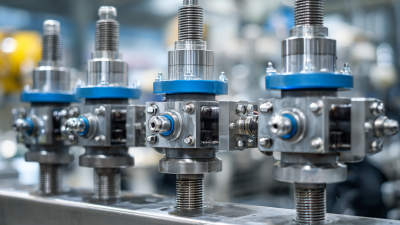

Understanding Cryogenic Solenoid Valves: Key Features and Benefits

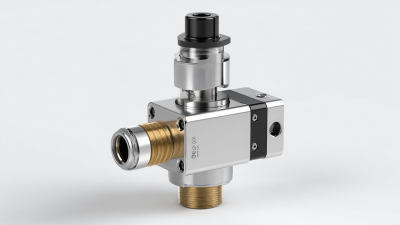

Cryogenic solenoid valves play a critical role in managing the flow of cryogenic fluids, such as liquefied natural gas (LNG) and liquid nitrogen, across various applications. These valves are specifically designed to operate efficiently at extremely low temperatures, often below -150°C, which is essential in industries like aerospace, medical, and energy. According to a report by MarketsandMarkets, the global cryogenic valve market is expected to reach USD 4.6 billion by 2025, highlighting the growing demand for reliable and efficient solutions in handling cryogenic materials.

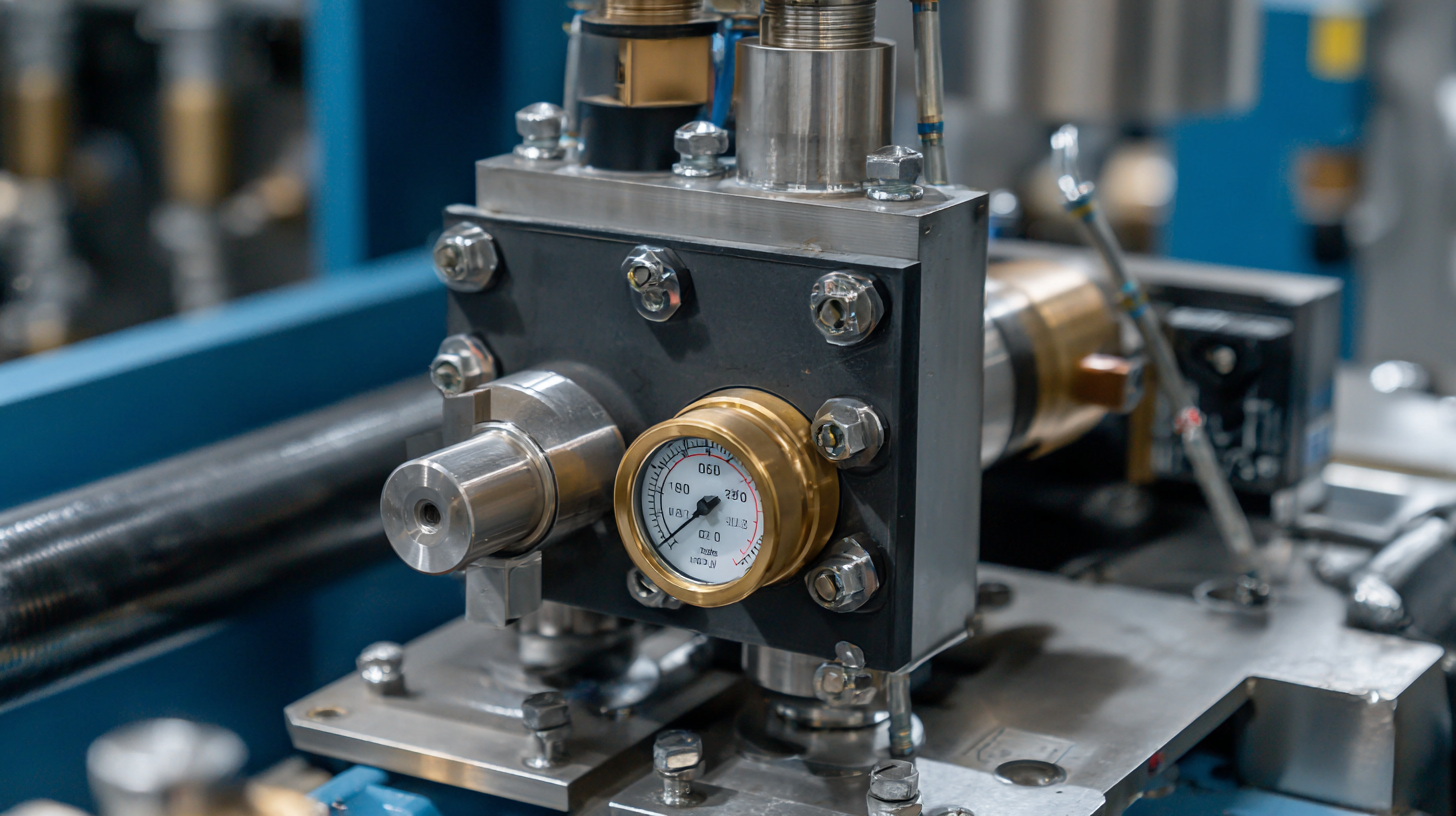

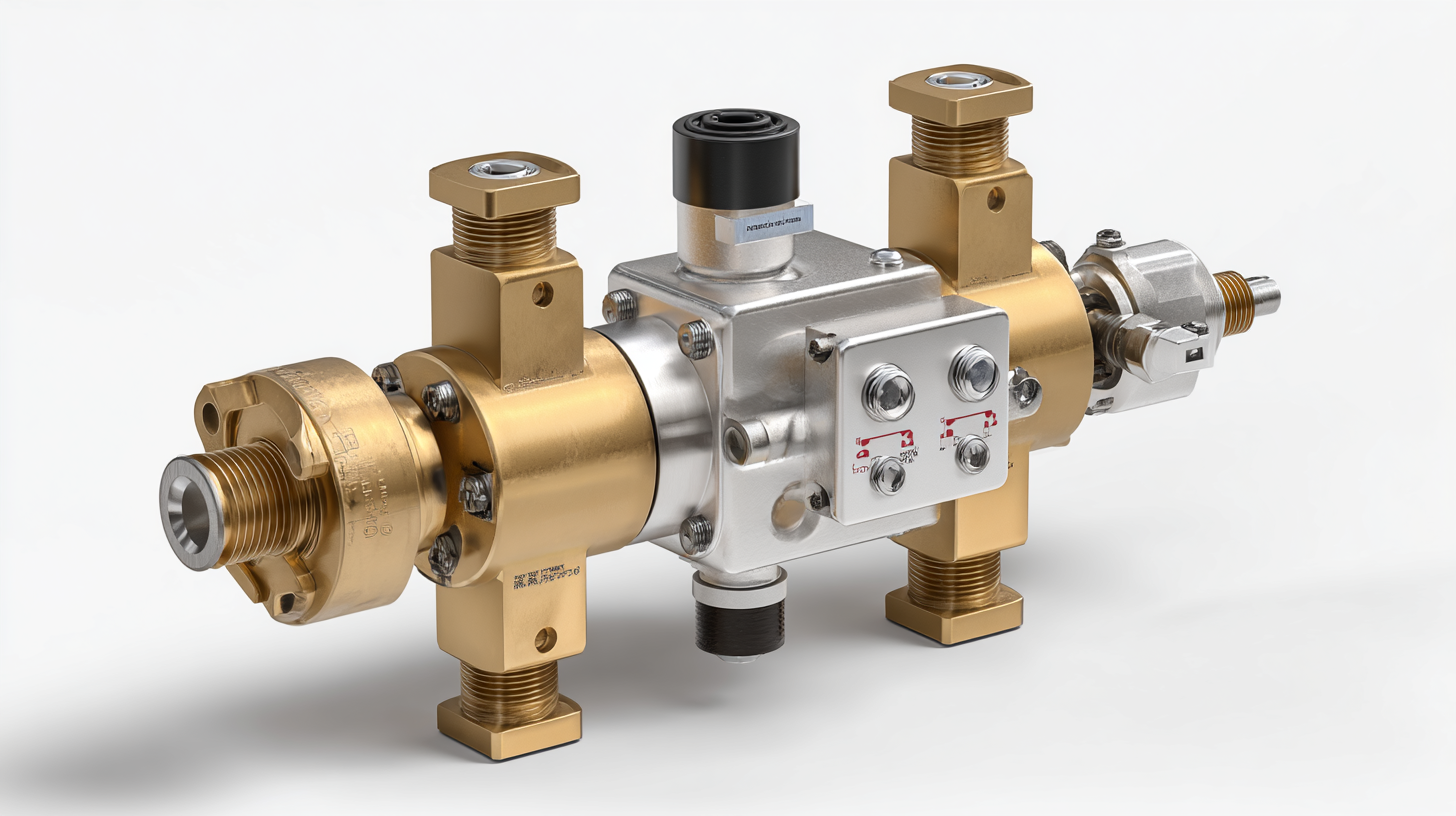

One of the key features of cryogenic solenoid valves is their robust construction, which often includes materials resistant to extreme cold and thermal cycling, such as stainless steel or specialized alloys. This durability ensures longevity and minimizes maintenance costs. Additionally, these valves are designed to provide quick response times, critical for processes that require precise flow control. A study published in the Journal of Cryogenics indicates that optimized solenoid valve designs can achieve over 95% efficiency, enabling facilities to operate with minimal energy loss while maximizing safety and performance during critical operations.

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

| Parameter | Value | Units | Application |

|---|---|---|---|

| Operating Temperature Range | -196 to +50 | °C | Cryogenic systems |

| Response Time | 15 | ms | Automation systems |

| Leak Rate | < 1 x 10-8 | mbar l/s | Cryogenic gas handling |

| Maximum Pressure | 200 | bar | Industrial applications |

| Voltage Rating | 24 | V DC | Control systems |

| Actuation Type | Electromagnetic | N/A | Fluid control |

Applications of Cryogenic Solenoid Valves in Industry and Research

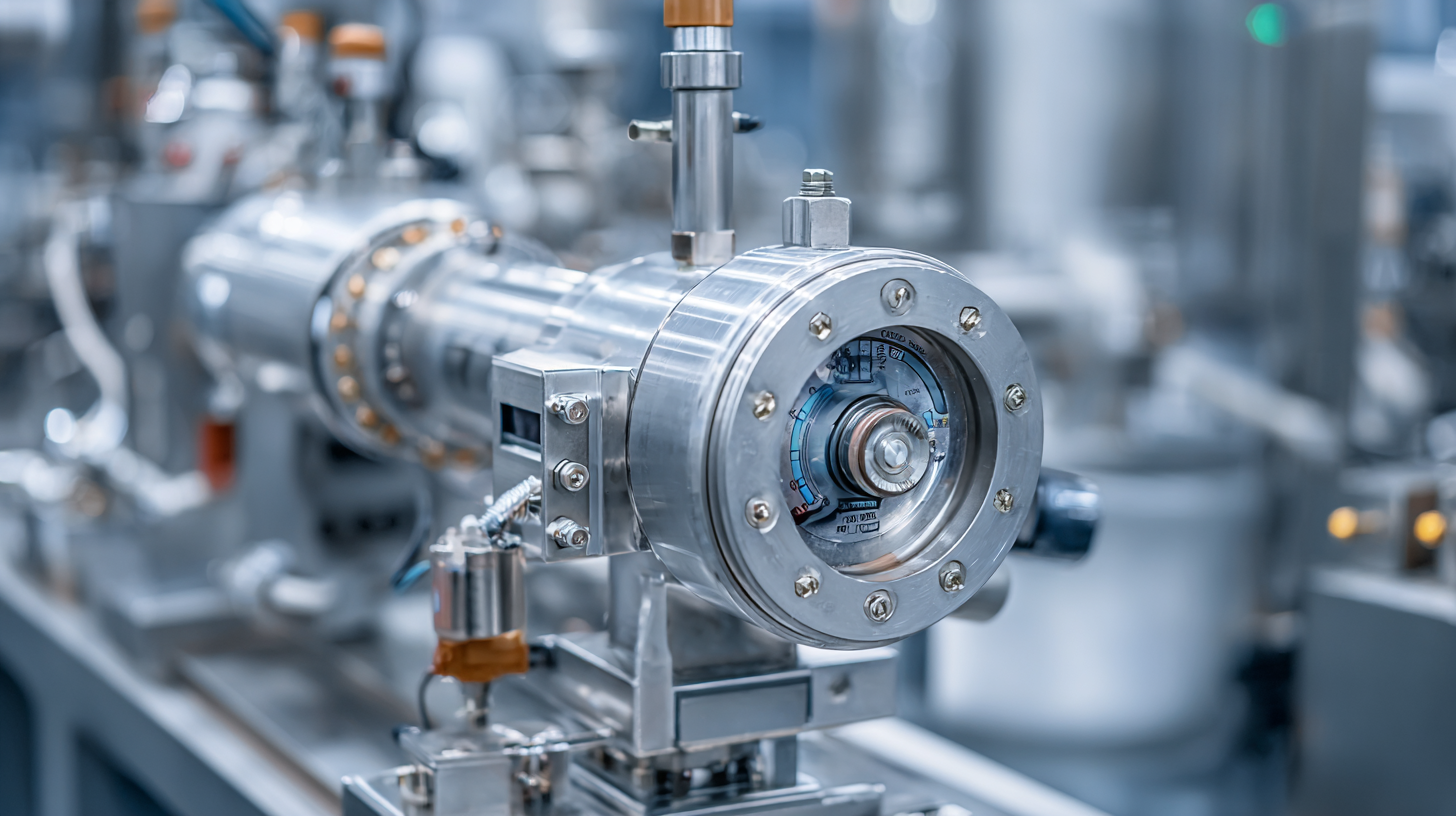

Cryogenic solenoid valves play a pivotal role in various industrial and research applications due to their ability to control the flow of cryogenic fluids effectively. These valves are particularly essential in sectors such as aerospace, where liquid hydrogen and helium are utilized as propellants and coolant agents. Their reliable operation under extremely low temperatures ensures safety and efficiency in handling these substances, which are critical for propulsion systems and testing facilities.

In the realm of scientific research, cryogenic solenoid valves are integral in laboratory settings, particularly in experiments requiring precise temperature control, such as quantum computing and superconductivity studies. Their rapid actuation and reliable sealing properties allow researchers to maintain the necessary cryogenic conditions, thereby enabling accurate and reproducible results. Furthermore, innovations in valve technology have expanded their applications, accommodating a wider range of fluids and pressures, thus enhancing their utility in diverse settings from medical equipment to cryopreservation processes.

Comparative Analysis of Performance Metrics in Cryogenic Systems

Cryogenic solenoid valves play a crucial role in enhancing the efficiency of various cryogenic systems, particularly in applications involving liquefied gases such as helium and nitrogen. The comparative analysis of performance metrics within these systems reveals significant differences in flow rates, response times, and operational reliability.

Specifically, valves designed for cryogenic applications demonstrate superior sealing capabilities and thermal stability, reducing energy losses and ensuring optimal flow control in extreme temperatures.

Moreover, performance metrics such as pressure drop and actuation speed serve as vital indicators of a solenoid valve's effectiveness in cryogenic environments. Detailed evaluations show that advanced materials and innovative designs contribute to reducing pressure drop across the valve, thereby improving overall system efficiency. Additionally, faster actuation times yield better system responsiveness, which is essential for applications requiring precise control under fluctuating thermal conditions. Such performance enhancements underscore the importance of selecting the appropriate cryogenic solenoid valve tailored to specific operational needs, ensuring maximum efficiency and reliability in critical cryogenic applications.

Maintenance Tips for Maximizing the Lifespan of Solenoid Valves

The efficient operation of cryogenic solenoid valves is crucial in various industrial applications, particularly in the aerospace, medical, and energy sectors. To ensure these valves function optimally, regular maintenance is essential. According to a report by the International Society for Automation, a significant percentage of solenoid valve failures can be traced back to improper maintenance practices. Regular inspection can help identify wear and tear, allowing for timely interventions that can prevent costly downtime.

To maximize the lifespan of solenoid valves, it is vital to maintain a clean environment free from contaminants that could affect their performance. Utilizing filters and ensuring that the valves are installed in locations that minimize exposure to dust and debris can make a notable difference. Additionally, periodic checks on the electrical connections, as highlighted in the 2022 Industrial Maintenance Report, indicate that inadequate power supply is one of the primary causes of operational failure. Implementing a maintenance schedule that includes these checks can significantly enhance the reliability of solenoid valves in cryogenic applications.

Performance Comparison of Cryogenic Solenoid Valves in Various Applications

This chart illustrates the flow rates of cryogenic solenoid valves used in various applications such as liquid nitrogen, liquid helium, cryogenic gas, and supercritical fluid, highlighting their performance for better maintenance and application efficiency.

Future Trends in Cryogenic Valve Technology and their Impact on Efficiency

Recent advancements in cryogenic valve technology have opened new avenues for enhancing efficiency across various applications. As industries increasingly rely on low-temperature processes, the development of cryogenic solenoid valves with improved materials and design has become crucial. These innovations enable better flow control, reduce leakage, and improve response times, significantly impacting operational efficiency. The use of advanced alloys and coatings enhances the durability of valves, ensuring they perform optimally even under extreme conditions.

Looking ahead, the integration of smart technologies in cryogenic valve systems is set to revolutionize their operation. The implementation of IoT-based monitoring and control systems will allow for real-time data collection and analysis, facilitating predictive maintenance and optimizing performance. Moreover, as industries strive for sustainability, the emphasis on energy-efficient designs and reduced emissions will further shape the future of cryogenic valve technology. Overall, these trends not only promise to enhance the performance of cryogenic solenoid valves but also play a pivotal role in meeting the evolving demands of industries such as aerospace, medical technology, and gas processing.

Related Posts

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications