Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications

In the realm of industrial safety, the high pressure relief valve plays a crucial role in protecting equipment and personnel from the dangers of excessive pressure. These vital components are designed to automatically release excess pressure from systems, thus preventing catastrophic failures that can lead to accidents and substantial financial losses.

In the realm of industrial safety, the high pressure relief valve plays a crucial role in protecting equipment and personnel from the dangers of excessive pressure. These vital components are designed to automatically release excess pressure from systems, thus preventing catastrophic failures that can lead to accidents and substantial financial losses.

Understanding how high pressure relief valves function is essential for engineers, technicians, and safety professionals alike. In this essential guide, we delve into the operational principles, design features, and maintenance practices crucial for ensuring the reliability of high pressure relief valves. By equipping yourself with knowledge about these mechanisms, you can foster a safer working environment, enhance system longevity, and comply with industry regulations.

Join us as we explore the intricacies of high pressure relief valves and their indispensable function in maintaining safety across various industrial applications.

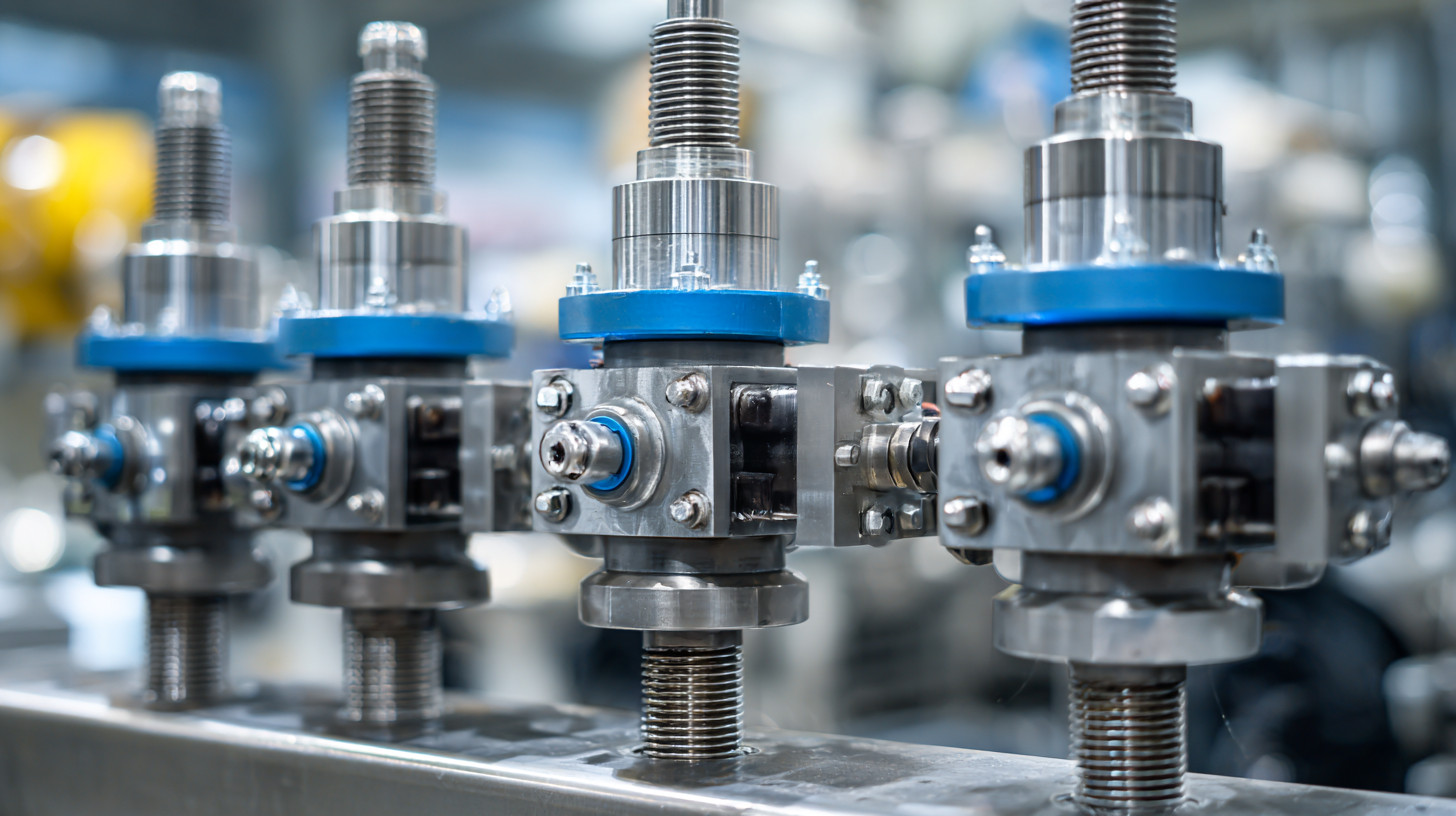

Understanding the Functionality of High Pressure Relief Valves in Industrial Systems

High pressure relief valves are critical components in industrial systems that play a vital role in maintaining safety. They are designed to automatically release excess pressure to prevent potential hazards such as equipment failure, explosions, or leaks. When the pressure within a system surpasses a predetermined limit, these valves open, allowing pressure to escape and effectively regulating the system’s overall pressure level. Understanding the functionality of these valves is essential for ensuring safety and efficiency in various industrial applications.

Tips: Regular maintenance checks are important to ensure your high pressure relief valves function correctly. Inspect them for signs of wear or corrosion, and ensure that the calibration is accurate. Implementing a routine testing schedule can help identify potential issues before they become critical.

Additionally, it’s crucial to select the appropriate type of relief valve based on the specific requirements of your system. Different applications may require different valve designs, pressure settings, and materials. Consider not only the operational pressure but also the type of fluids handled, as these factors significantly impact the performance and longevity of the valve.

Tips: Consult with a qualified engineer when selecting and installing relief valves. Their expertise can help you make informed decisions that enhance both safety and efficiency in your operations.

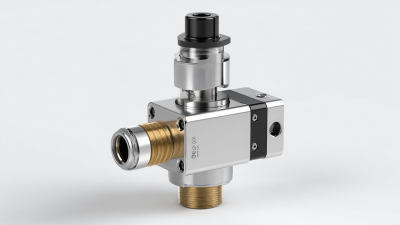

Identifying Different Types of High Pressure Relief Valves and Their Applications

High pressure relief valves (HPRVs) are crucial components in industrial systems, designed to protect equipment and ensure safety by preventing excessive pressure build-up. There are several types of HPRVs, each tailored for specific applications. For instance, spring-loaded relief valves are widely used in petrochemical industries, where they respond quickly to pressure surges, providing reliable protection. According to a recent report by the American Petroleum Institute, over 30% of industrial accidents are attributable to pressure system failures, emphasizing the importance of these valves in maintaining system integrity.

Another notable type includes pilot-operated relief valves, which are ideal for high-pressure applications due to their ability to manage large fluid flows effectively. These valves utilize system pressure to assist operation, making them more efficient for critical applications such as gas transmission and chemical processing. In these sectors, accurate pressure regulation is vital, as highlighted by a study from the Hydraulic Institute, indicating that proper use of HPRVs can reduce incident rates by up to 50%. Understanding the various types and their specific applications not only enhances safety measures but also ensures compliance with industry standards, reinforcing the pivotal role of high pressure relief valves in safeguarding industrial operations.

Essential Guide to Understanding High Pressure Relief Valves

| Valve Type | Application | Typical Pressure Range | Material | Key Features |

|---|---|---|---|---|

| Spring-loaded Relief Valve | Oil and Gas | 100 - 3000 psi | Stainless Steel | High reliability, compact design |

| Pilot-operated Relief Valve | Chemical Processing | 150 - 5000 psi | Carbon Steel | Self-adjusting, minimizes leakage |

| Depressurization Valve | Water Systems | 50 - 150 psi | Brass | Corrosion-resistant, easy maintenance |

| Safety Relief Valve | Power Generation | 200 - 6000 psi | Alloy Materials | Fast response, high capacity |

| Discharge Relief Valve | Pharmaceuticals | 100 - 2000 psi | Nickel Alloy | Sanitary design, accurate control |

Steps to Properly Select a High Pressure Relief Valve for Your Process

When selecting a high pressure relief valve for your industrial processes, it's vital to consider several key factors to ensure optimal safety and efficiency. Firstly, understanding the specific pressure requirements of your operation is essential. According to the American Society of Mechanical Engineers (ASME), proper sizing is critical; a valve that is too small can cause overpressure, while one that is too large may lead to unnecessary cycling. It’s recommended to consult ASME’s guidelines on safe pressure relief mechanisms to align your selection with established industry standards.

Tips: Always verify the manufacturer's data sheets to cross-reference the valve's performance capabilities with your process parameters, including pressure fluctuations and temperature influences. This ensures the valve can handle your specific conditions without failure.

Another vital aspect is the material selection for the valve. Depending on the media being processed, some materials may be more suitable than others to withstand corrosive or high-temperature environments. The National Board of Boiler and Pressure Vessel Inspectors emphasizes the importance of compatibility to avoid premature failure. Ensure you consult compatibility charts and consider your operational environment when making your selection.

Tips: Regularly re-evaluate your valve's performance and the conditions of your operations. Continuous monitoring and periodic maintenance can significantly prolong the life of your pressure relief valves and maintain system integrity.

Best Practices for Maintaining and Testing High Pressure Relief Valves

High pressure relief valves (HPRVs) are critical components in maintaining safety within various industrial applications. Ensuring their optimal performance requires diligent maintenance and regular testing. According to the American Society of Mechanical Engineers (ASME), nearly 60% of industrial incidents related to pressure systems can be traced back to malfunctioning safety valves, emphasizing the importance of adhering to established best practices.

To maintain the efficiency of HPRVs, operators should implement a routine inspection schedule. It is recommended that valves undergo testing at least annually or as dictated by the specific industry standard. Inspections should focus on identifying wear and tear, ensuring proper seating, and verifying that the set pressure is within acceptable limits.

Tips: Regularly cleaning the valve and surrounding area can prevent debris buildup that may affect functionality. Additionally, using a calibration test bench can help ensure that the valves operate at the set pressure, contributing to overall system reliability.

Another vital practice is to document all maintenance and testing activities. This documentation not only helps in compliance with regulatory standards but also serves as a historical reference for performance tracking. Regular audits revealing that proper maintenance protocols are followed can mitigate the risk of unplanned shutdowns and costly repairs, thus preserving safety and operational efficiency.

Common Safety Standards and Regulations for High Pressure Relief Valves in Industries

High-pressure relief valves (PRVs) are critical components in many industrial applications, ensuring operational safety and compliance with safety regulations. With the implementation of new national standards on September 1, these valves must adhere to updated safety norms that govern their design and functionality. This shift aims to bolster the safety mechanisms in industries where high-pressure systems are prevalent, including energy and manufacturing sectors. The new regulations emphasize rigorous testing and certification processes to mitigate risks associated with pressure failures.

In addition to the regulatory changes, the market for high-pressure processing machinery continues to expand, driven by stringent safety requirements in the food processing industry and the burgeoning electric vehicle sector. As these industries grow, the demand for reliable and efficient high-pressure relief valves has become paramount. Manufacturers are now focusing on developing products that not only meet but exceed safety standards, thereby enhancing overall system reliability and ensuring user protection. As these advancements roll out, adherence to the latest standards will be vital for industry players committed to maintaining safety and operational integrity.

High Pressure Relief Valves - Safety Compliance Statistics

This chart illustrates the number of compliance cases for various safety standards related to high pressure relief valves in industrial applications during the year 2022. Compliance with these standards is crucial for ensuring safety in high-pressure environments.