Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

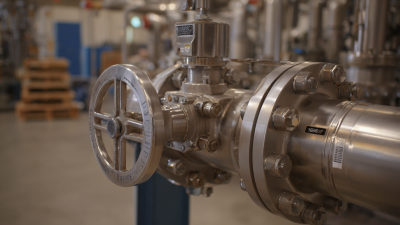

In the complex landscape of modern industrial systems, the significance of pressure vacuum valves cannot be overstated. These critical components play a vital role in maintaining the safety and efficiency of various applications, particularly in industries such as petroleum refining, chemical manufacturing, and hydrocarbon storage. According to a recent report by the Global Industry Analysts, the global market for pressure vacuum valves is projected to reach USD 1.3 billion by 2026, driven by increasing regulatory requirements and advancements in valve technology.

As industries strive for operational excellence, the integration of reliable pressure vacuum valves becomes essential to prevent catastrophic failures and product losses caused by vapor control issues. This underscores the need for a deeper understanding of their functions and benefits within industrial systems, highlighting the role these valves play in managing pressure differentials and ensuring environmental compliance.

How to Identify the Right Pressure Vacuum Valve for Your Industrial System

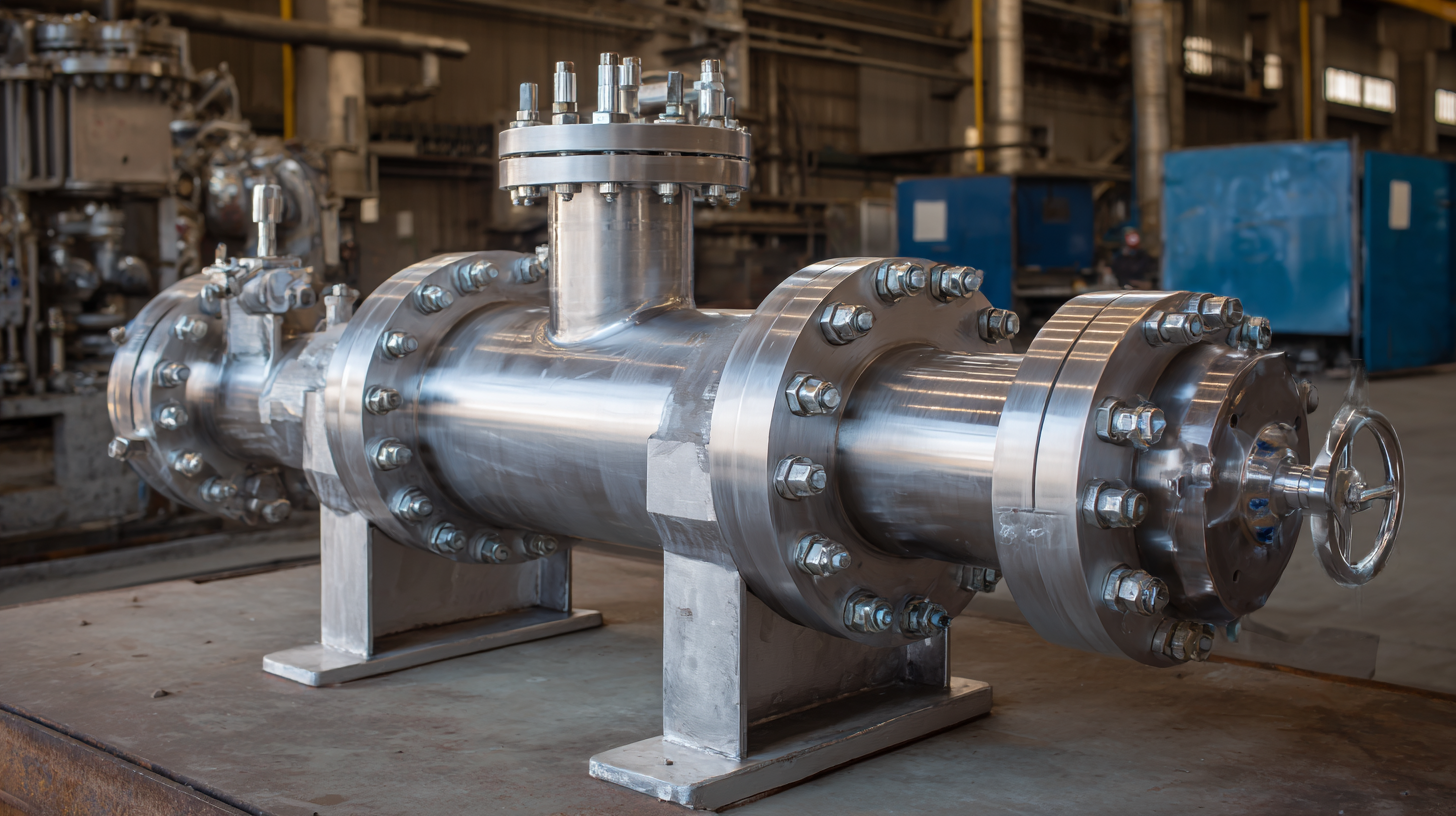

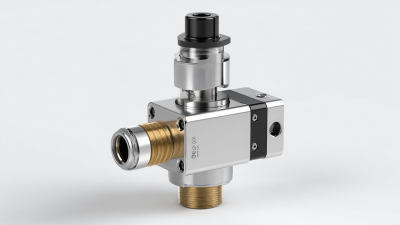

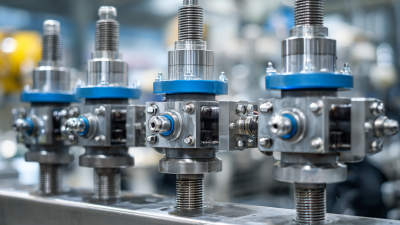

When selecting the right pressure vacuum valve for your industrial system, it's essential to consider various factors that will ensure optimal performance and safety. First, assess the specific needs of your application, including the types of fluids handled, operating pressure ranges, and temperature conditions. This initial evaluation helps narrow down valve types, such as direct-operated or pilot-operated valves, which can influence the valve's responsiveness and efficiency in your system.

Next, examine the materials of construction to match the valve's durability with the process requirements. Valves made from stainless steel or specialized polymers may offer resistance to corrosion and wear, while also being compatible with the fluids in your system. Additionally, consider the valve size and connection type, as these factors will affect installation and integration within existing systems. By understanding these key elements, you can make an informed decision that enhances the reliability and functionality of your industrial processes.

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems - How to Identify the Right Pressure Vacuum Valve for Your Industrial System

| Valve Type | Pressure Rating (psi) | Vacuum Rating (inHg) | Material | Application |

|---|---|---|---|---|

| Spring Loaded | 150 | 29.9 | Stainless Steel | Oil and Gas |

| Pilot Operated | 200 | 28.5 | Cast Iron | Chemical Processing |

| Weight Loaded | 100 | 30.0 | Brass | Water Treatment |

| Dual Function | 250 | 29.0 | Plastic | Food and Beverage |

| Vacuum Breaker | 75 | 15.0 | Aluminum | HVAC Systems |

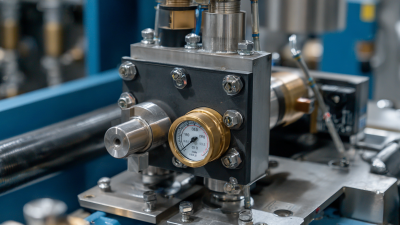

How to Maintain and Service Pressure Vacuum Valves for Optimal Performance

Pressure vacuum valves (PV valves) play a critical role in maintaining the integrity of industrial systems, ensuring safety and efficiency during operation. Regular maintenance is essential to uphold their optimal performance, as a malfunctioning valve can lead to undesired pressure variations, potential system failures, and costly downtimes. According to a study by the American Society of Mechanical Engineers (ASME), a well-maintained PV valve can improve system efficiency by as much as 15%, highlighting the importance of diligent servicing.

To maintain these valves effectively, it is crucial to conduct routine inspections and replace any worn components. Experts recommend checking the seals and valve bodies for any signs of wear or damage every six months. Additionally, ensuring that the valves are free from debris and contaminants will facilitate smooth operation.

**Tips for Maintenance:**

1. **Regular Lubrication:** Apply appropriate lubricant to moving parts to prevent wear and ensure seamless operation.

2. **Visual Inspections:** Conduct regular visual checks for leaks or corrosion, which can indicate underlying issues.

3. **Testing for Functionality:** Perform functional tests periodically to verify that the valves respond accurately to pressure fluctuations, thus preventing unexpected failures.

By prioritizing these maintenance practices, industries can enhance the lifespan and reliability of pressure vacuum valves, contributing to overall system efficiency.

Pressure Vacuum Valves Maintenance and Service Metrics

How to Integrate Pressure Vacuum Valves into Existing Industrial Processes

Integrating pressure vacuum valves into existing industrial processes is vital for optimizing system performance and maintaining safety standards. To achieve a seamless integration, one must first conduct a thorough assessment of the current system configuration. This involves identifying potential areas where pressure vacuum valves can enhance operational efficiency or enhance safety measures. For instance, during the transfer of liquids in tanks, these valves can effectively regulate pressure fluctuations, preventing dangerous conditions like tank implosions or overpressure scenarios.

Once the assessment is complete, the next step is to select appropriate pressure vacuum valves based on the specific requirements of the industrial process. Factors such as the type of fluids handled, operating temperature, and pressure ratings play a crucial role in this selection. Proper installation is equally important; valves should be strategically placed to ensure maximum effectiveness, often requiring collaboration with engineering teams for optimal positioning. Additionally, training personnel on the functionality and maintenance of these valves can significantly contribute to a successful integration, ensuring that the system operates efficiently and safely over time.

How to Troubleshoot Common Issues with Pressure Vacuum Valves

Pressure vacuum valves play a crucial role in maintaining the integrity and functionality of modern industrial systems. However, like any mechanical component, they can encounter issues that require troubleshooting. Understanding common problems associated with pressure vacuum valves can help you resolve them quickly and effectively.

**Tips:** Regularly inspect the valve for signs of wear or damage. Loose fittings or leaks can often be tightened or sealed. If the valve fails to operate properly, ensure that it is not blocked by debris or sediment; cleaning the valve can often restore its function.

Another common issue is pressure imbalance. If you notice fluctuations in pressure, it might be due to a malfunctioning sensor or incorrect valve settings. In such cases, check the calibration of the system and adjust as necessary. Keeping a maintenance log can also help identify recurring issues before they escalate into significant problems.

**Tips:** Always refer to the manufacturer’s guidelines for specific troubleshooting steps. Having replacement parts on hand can save time during repairs. Additionally, consulting with a professional can provide insights into more complex issues.

How to Select the Best Materials for Pressure Vacuum Valve Applications

When selecting materials for pressure vacuum valves, it is crucial to consider factors such as pressure ratings, temperature ranges, and the chemical compatibility of the materials with the fluids being controlled. Commonly used materials include brass, stainless steel, and various polymers. Brass and stainless steel are popular for their durability and resistance to corrosion, making them suitable for a wide array of industrial applications. In contrast, polymers may be more appropriate for applications requiring lightweight solutions or where chemical exposure demands non-reactive materials.

Additionally, the valve's operational environment plays a significant role in material selection. High-temperature environments may necessitate the use of specialized alloys or heat-resistant materials to ensure safety and longevity. Furthermore, industries that handle aggressive chemicals may require valves made from PTFE or other high-performance plastics to prevent degradation. Thus, a thorough assessment of the application’s specific requirements is essential for choosing the right material, ensuring optimal performance and reliability of pressure vacuum valves.

Related Posts

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications