Top 10 Essential Valve Tags for Efficient Industrial Safety Management

In the realm of industrial safety management, the significance of effective communication cannot be overstated. One of the key components in ensuring that safety protocols are understood and followed is the implementation of clearly labeled valve tags. According to a recent report by the Occupational Safety and Health Administration (OSHA), improper valve identification contributes to 30% of workplace accidents involving hazardous materials. This alarming statistic underscores the critical need for comprehensive valve tagging systems that aid in risk reduction and compliance.

As industry expert Dr. Jonathan Davis states, "A well-implemented valve tag system not only enhances safety but also streamlines operational efficiency, allowing workers to quickly identify and manage potentially dangerous situations." In light of such insights, this article delves into the "2025 Top 10 Essential Valve Tags" that are pivotal in fostering a safety-first culture within industrial environments. By examining these essential tags, businesses can better navigate the complexities of safety management, reduce liability, and safeguard their workforce—all while adhering to the latest regulatory standards.

Top 10 Valve Tags: Enhancing Industrial Safety and Efficiency

In today's industrial landscape, ensuring safety and operational efficiency is paramount. One pivotal tool in achieving this is the effective use of valve tags. According to a report by the National Safety Council, nearly 4 million workplace injuries occur annually, many of which stem from inadequate safety protocols. Implementing clear and informative valve tags plays a crucial role in mitigating these risks, as they provide immediate identification and instructions, reducing the likelihood of accidents.

Moreover, the American Society of Mechanical Engineers (ASME) highlights that standardized labeling in industrial environments can increase efficiency by up to 30%. Proper valve tags not only streamline operations but also ensure compliance with safety regulations. By consistently utilizing tags that indicate valve functions, flow direction, and maintenance schedules, companies can reduce downtime and enhance communication among staff. This reinforces the idea that investing in essential valve tags can lead to substantial improvements in both safety measures and overall operational productivity.

Top 10 Essential Valve Tags for Efficient Industrial Safety Management

Key Features of Essential Valve Tags for Industrial Settings

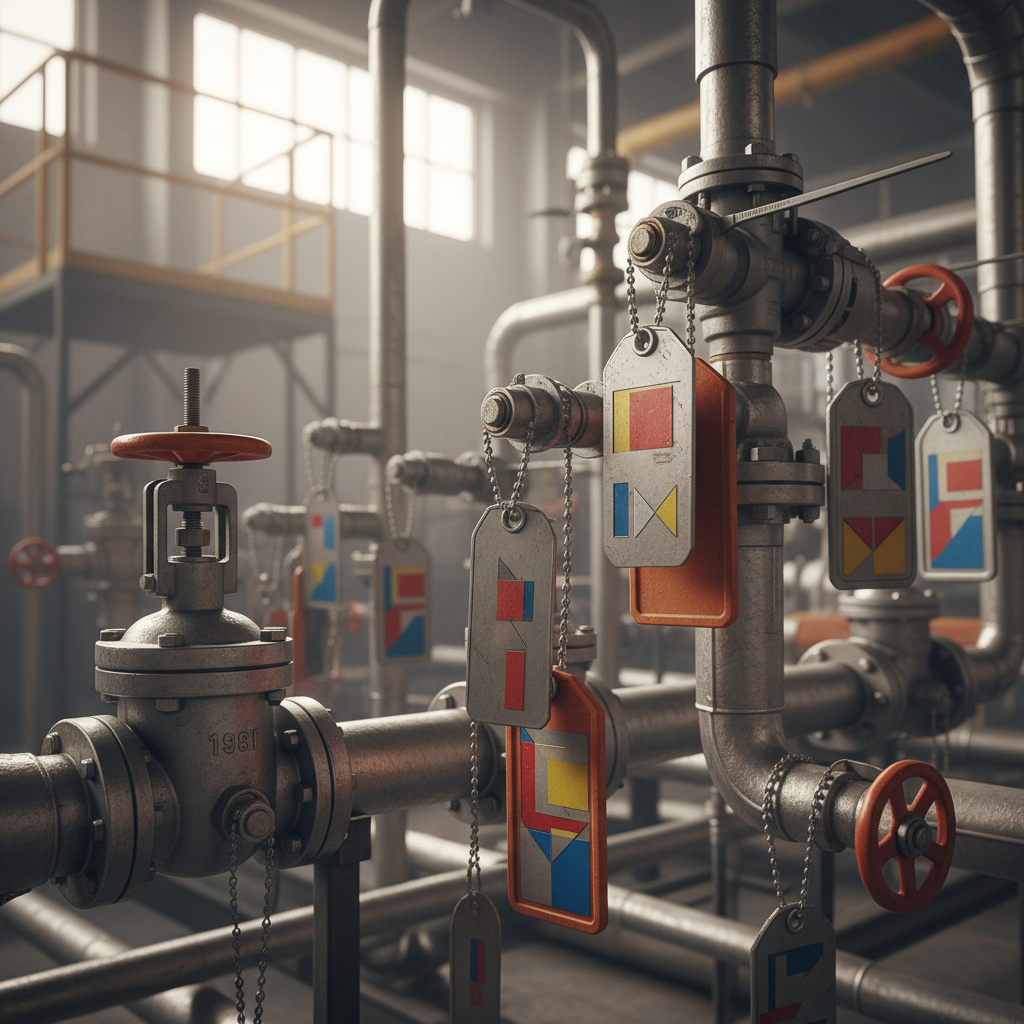

Effective industrial safety management relies heavily on the use of essential valve tags that promote clear communication and operational efficiency. One of the key features of these tags is their durability. Fabricated from materials like stainless steel or high-grade plastic, these tags can withstand harsh environmental conditions, including extreme temperatures, chemicals, and UV exposure. This longevity ensures that important information remains legible and intact over time, reducing the risk of accidents due to miscommunication.

Another vital aspect of valve tags is their design, which prioritizes visibility and readability. High-contrast colors and large, bold fonts allow workers to quickly identify valve functions and statuses, even from a distance. Additionally, customizable options enable the inclusion of specific information such as flow direction, maintenance schedules, or emergency contact details. This personalized approach not only enhances safety protocols but also streamlines operational processes, ensuring that teams can respond rapidly in critical situations. In an industrial setting, these features collectively contribute to a safer, more efficient workplace.

Best Practices for Implementing Valve Tags in Safety Protocols

Implementing valve tags effectively is crucial for maximizing industrial safety protocols. First and foremost, organizations must ensure that the valve tags are clear, durable, and easily readable. Tags should be color-coded or labeled according to the standard operating procedures, allowing operators to swiftly identify the function and status of each valve in high-pressure environments. Regular audits should also be conducted to verify the condition and visibility of the tags, as worn-out or illegible tags can lead to critical mistakes during operation.

Another best practice is integrating training sessions focused specifically on the use of valve tags within safety management systems. Employees should be well-versed in the significance of valve tagging, understanding how each tag contributes to overall safety and operational efficiency. Simulating real-life scenarios where valve tags are essential can reinforce their importance and help eliminate human error under pressure. By promoting a culture of safety awareness and diligence surrounding valve documentation, industries can further enhance their safety management protocols.

Digital Innovations in Valve Tagging for Improved Safety Management

The landscape of industrial safety management is rapidly changing with the advent of digital innovations in valve tagging. Traditional methods often fall short in providing clear visibility and tracking of critical valves. However, modern digital solutions, such as QR codes and RFID tags, are transforming how facilities manage safety protocols. These innovations enable real-time data access, ensuring that safety measures are not only documented but easily retrievable. Operators can quickly scan tags to identify valve status and history, significantly reducing the risk of errors during maintenance and operations.

Moreover, digital valve tagging enhances communication across teams by standardizing information-sharing processes. With centralized databases, everyone from operators to safety managers can access up-to-date valve information, improving situational awareness and response times in emergencies. This interconnected system supports compliance with safety regulations while fostering a culture of diligence and accountability. As the industry continues to embrace technology, the implementation of digital tagging systems will be crucial in enhancing the overall efficiency and safety management of industrial operations.

Top Considerations When Choosing Valve Tags for Your Facility

When selecting valve tags for your facility, there are several crucial considerations to keep in mind to ensure effective industrial safety management. According to a recent report by the American National Standards Institute (ANSI), proper identification of valves can reduce incidents related to misoperation or neglect by up to 30%. This statistic underscores the importance of clear and durable tagging systems that are capable of withstanding harsh industrial environments.

The material of valve tags is a key factor that impacts their longevity and visibility. Corrosion-resistant materials, such as stainless steel or anodized aluminum, are often recommended for facilities exposed to extreme weather or chemicals. Furthermore, the ability to incorporate color coding and clear, large-font labeling can enhance quick identification, particularly in emergency situations. A study published in the Journal of Safety Research highlights that workplaces that implement color-coded systems report a 25% increase in safety response times. These considerations not only foster a safer work environment but also support compliance with industry regulations, ensuring that your facility can operate smoothly and efficiently.

Related Posts

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

Top 10 Check Valve Types for Optimal Flow Control and Industry Applications

-

Understanding the Key Benefits of Using Ball Valves in Modern Plumbing Systems

-

Top 10 Types of Valves: Unlocking Key Insights for Industrial Efficiency

-

Top 10 Hydrogen Valves for Optimal Performance and Safety in Applications

-

Understanding the Importance of Control Valves in Modern Industrial Applications