10 Expert Tips for Choosing the Right Liquid Nitrogen Valve for Your Needs

In the realm of cryogenics, the selection of a liquid nitrogen valve is paramount for ensuring safety and efficiency in various applications. John Smith, a renowned expert in the liquid nitrogen industry and a senior engineer at CryoTech Solutions, emphasizes, "Choosing the right liquid nitrogen valve can significantly affect both the performance and safety of your operations." With the growing demand for liquid nitrogen in fields ranging from medical research to industrial processes, understanding the nuances of these valves has never been more critical.

When considering which liquid nitrogen valve best suits your needs, various factors come into play, including material compatibility, pressure ratings, and the specific requirements of your application. The right valve not only optimizes performance but also minimizes the risk of leaks and other potential hazards. As we delve deeper into this topic, we will explore 10 expert tips that can guide you in making an informed choice, ensuring that your liquid nitrogen handling is both effective and secure.

Understanding Liquid Nitrogen Valve Types and Their Applications

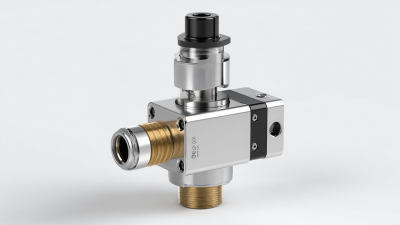

When selecting a liquid nitrogen valve, it's crucial to understand the various types available and their specific applications. Typically, liquid nitrogen valves can be categorized into two main types: manual valves and automatic valves. Manual valves are operated by hand and offer precise control, making them suitable for laboratory settings where operators require direct oversight of the flow. On the other hand, automatic valves are designed for more complex systems and can be controlled remotely, which is ideal for industrial applications where safety and efficiency are paramount.

Each valve type also has unique features catering to specific operational requirements. For instance, some models are built with unique materials to withstand extremely low temperatures, while others may offer enhanced sealing capabilities to prevent leaks. Applications vary widely from cryopreservation in medical laboratories to cooling in industrial processes. Understanding these distinctions ensures you select a valve that not only meets your operational needs but also adheres to safety regulations and maintains system integrity.

10 Expert Tips for Choosing the Right Liquid Nitrogen Valve for Your Needs

| Valve Type | Primary Application | Max Pressure (psi) | Temperature Range (°F) | Material |

|---|---|---|---|---|

| Cryogenic Globe Valve | Storage Tank Systems | 300 | -320 to 140 | Stainless Steel |

| Cryogenic Ball Valve | Transfer Lines | 400 | -320 to 150 | Bronze |

| Cryogenic Relief Valve | Safety Systems | 250 | -260 to 120 | Inconel |

| Cryogenic Needle Valve | Precise Flow Control | 150 | -320 to 140 | Carbon Steel |

| Cryogenic Check Valve | Prevent Backflow | 300 | -320 to 140 | Aluminum |

Key Features to Evaluate When Selecting a Liquid Nitrogen Valve

When selecting a liquid nitrogen valve, it is essential to evaluate several key features to ensure optimal performance and safety. The design of the valve is critical; it should offer a robust construction that can withstand extreme temperatures, often as low as -196°C. According to a recent report by the Cryogenic Society, over 70% of valve failures arise from inadequate material specifications. Therefore, opting for valves made from high-quality stainless steel or specialized alloys can significantly reduce the risk of failure.

Another important factor is the valve’s flow rate, which directly influences the efficiency of the application. Industry standards indicate that valves should be selected based on the specific flow requirements of the intended use—such as cryopreservation or industrial applications. A report from the International Institute of Cryogenics highlights that mismatched flow rates can lead to inefficient operation and increased operational costs. Additionally, consider the ease of maintenance and availability of replacement parts, as this is paramount for minimizing downtime in commercial settings.

Essential Safety Considerations for Liquid Nitrogen Valve Usage

When dealing with liquid nitrogen valves, safety is paramount. Liquid nitrogen, while an indispensable asset in numerous scientific and industrial applications, poses significant risks if not handled correctly. One of the basic safety considerations is to always wear appropriate personal protective equipment (PPE) such as cryogenic gloves, goggles, and a face shield. This is crucial for protecting oneself against the extreme cold and potential splashes of liquid nitrogen.

In addition to wearing the right gear, it's essential to ensure that the chosen valve is designed for cryogenic applications. Not all valves can withstand the extreme temperatures associated with liquid nitrogen, so evaluating the specifications becomes a key factor. Additionally, consider purchasing a valve with built-in safety features, such as pressure relief mechanisms, to prevent any dangerous situations arising from overpressure or rapid expansion.

Finally, regular maintenance and inspections of liquid nitrogen valves are vital for safe operation. Check for any signs of wear and tear or freezing effects that could impede functionality. Proper training in handling these components will also equip users to respond appropriately to unexpected incidents, making safety an integral part of your liquid nitrogen management strategy.

Maintenance Tips for Prolonging the Life of Your Liquid Nitrogen Valve

When it comes to maintaining liquid nitrogen valves, proper care can significantly extend their lifespan and efficiency. Regular maintenance should follow a structured plan, similar to the recommendations for winterizing logging fleets, which emphasizes the importance of sticking to a maintenance schedule for optimal equipment performance.

One key tip is to regularly inspect the valve for any signs of wear or damage. Ensure all seals and gaskets are intact to prevent leaks, as these can compromise the valve’s efficiency. Additionally, lubricating moving parts with suitable lubricants can help reduce friction, promoting smoother operation and reducing the risk of mechanical failure.

Another important aspect is to keep the valve and surrounding area clean. Contaminants can lead to corrosion and other issues that affect performance. Implementing a routine cleaning protocol not only helps maintain the valve in good condition but also contributes to the overall safety of the equipment. Remember, proactive maintenance is always more cost-effective than reactive repairs.

Cost-Effectiveness: Balancing Quality and Budget in Valve Selection

When selecting the right liquid nitrogen valve, cost-effectiveness is a crucial factor that requires careful consideration. Balancing quality and budget can significantly impact the overall efficiency and safety of your operations. It's essential to choose a valve that meets industry standards without compromising on performance. This means investing in a high-quality product that will last longer and require less maintenance, ultimately saving you money in the long run.

One of the first tips is to assess the specific requirements of your application. Understanding the pressure, temperature, and flow rate needs allows you to narrow down your options effectively. Additionally, consider the materials used in the valve construction. Investing in a valve made from durable materials, such as stainless steel, can provide long-term value despite an initially higher purchase price.

Another important point is to research and compare providers. Look for manufacturers or suppliers that offer a warranty and reliable customer support. This can safeguard your investment and ensure you receive guidance for any issues that arise. Finally, don't hesitate to ask for recommendations from industry experts or peers who have experience with liquid nitrogen valves. They can provide valuable insights that align with both your budget constraints and quality expectations.

Related Posts

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Why Choosing the Right Pressure Relief Valve is Essential for Safety and Efficiency

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

How to Choose the Right Air Valve for Your Pneumatic System Needs