Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers

The evolution of ball valve manufacturers is significantly influenced by advancements in technology and the increasing demand for automation and efficiency across various industries. According to a recent market analysis by Research and Markets, the global ball valve market is projected to reach USD 14.63 billion by 2026, growing at a CAGR of 5.1%. This growth is driven by key innovations such as IoT integration, which allows for remote monitoring and predictive maintenance, thereby enhancing operational productivity and reducing downtime.

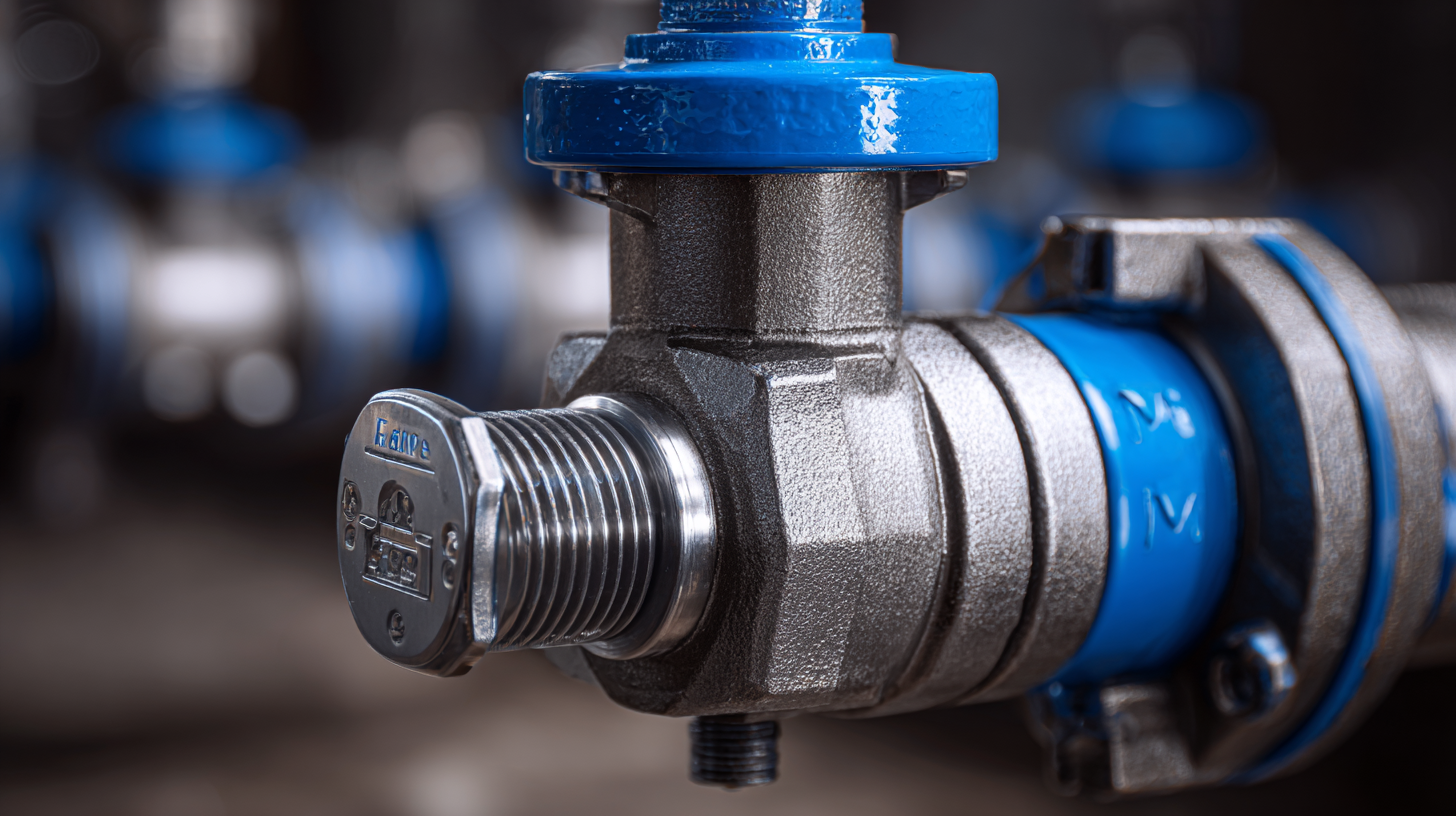

Additionally, the incorporation of advanced materials has resulted in more durable and corrosion-resistant valves, catering to the stringent requirements of sectors such as oil and gas, water treatment, and chemical processing. As ball valve manufacturers adapt to these trends, they will be at the forefront of delivering solutions that not only meet regulatory standards but also drive sustainability initiatives.

Understanding the Role of Smart Technology in Ball Valve Manufacturing

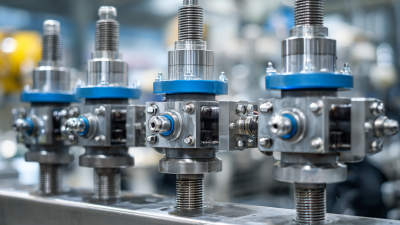

The integration of smart technology in ball valve manufacturing is revolutionizing the industry, enhancing efficiency and precision in production processes. Advanced automation systems now enable manufacturers to monitor and control valve operations in real-time, significantly reducing the risk of errors and minimizing waste. By utilizing Internet of Things (IoT) sensors, manufacturers can gather critical data on valve performance, leading to proactive maintenance and improved product reliability.

Furthermore, the advent of artificial intelligence (AI) in design and production has allowed for the development of more sophisticated ball valves tailored to meet specific industry needs. Machine learning algorithms analyze vast amounts of data, facilitating the identification of optimal designs and materials while streamlining the manufacturing process. As smart technology continues to evolve, it not only drives innovation in product offerings but also empowers ball valve manufacturers to adapt quickly to market demands, ensuring they remain competitive in an ever-changing landscape.

Adopting Advanced Materials for Enhanced Durability and Performance

In recent years, the ball valve manufacturing industry has witnessed significant advancements driven by the adoption of advanced materials. These materials are not only enhancing the durability of ball valves but also improving their overall performance in various applications. Manufacturers are increasingly utilizing composites and specialized alloys that offer higher resistance to corrosion, wear, and thermal stress. This shift towards innovative materials ensures that ball valves can operate effectively in demanding environments, such as oil and gas, chemical processing, and water treatment facilities.

Moreover, the integration of advanced materials leads to a reduction in weight without compromising strength. Lighter valves contribute to easier installation and maintenance, ultimately resulting in lower operational costs for companies. The use of materials like high-performance plastics in conjunction with traditional metals is also paving the way for designs that enhance flow characteristics and minimize leakage, which is crucial for maintaining system efficiency and safety. As the industry continues to evolve, staying at the forefront of material science will be key for manufacturers aiming to deliver products that meet the growing demands for reliability and functionality.

Integrating Automation and IoT for Streamlined Production Processes

The integration of automation and IoT in the manufacturing sector is revolutionizing production processes, particularly for ball valve manufacturers. With the global IoT in manufacturing market poised to grow from $116.52 billion in 2024 to $141.18 billion in 2025, embracing such technologies is no longer a choice but a necessity. Manufacturers are increasingly turning to system integrators to enhance process efficiency, as the market for system integration in industrial automation is expected to achieve a 3.42% CAGR from 2025 to 2035.

Emerging technologies such as robotic process automation (RPA) are proving crucial in optimizing efficiency and bridging workforce gaps. The digital manufacturing market is also on a significant upward trajectory, with projections indicating a market size reaching around $1,631.0 billion by 2034, growing at a CAGR of 15%. This showcases a wealth of investment opportunities for companies ready to harness the power of digital transformation.

**Tips:** For manufacturers looking to upgrade their processes, investing in IoT solutions can lead to increased visibility and control over operations. Additionally, prioritizing RPA can enhance precision and reduce operational costs. As these technologies continue to evolve, staying informed will be key to maintaining a competitive edge in the market.

Innovations in Ball Valve Manufacturing: Automation and IoT Impact

Utilizing 3D Printing for Customization and Rapid Prototyping

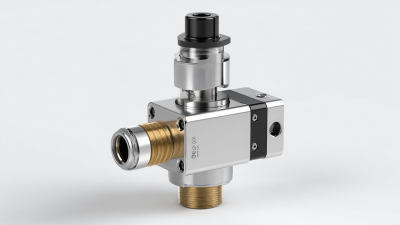

The integration of 3D printing technology is revolutionizing the ball valve manufacturing industry by enabling customization and rapid prototyping like never before. Traditionally, the production of ball valves involved lengthy design and manufacturing processes, often leading to delays and high costs. However, with 3D printing, manufacturers can quickly create complex designs tailored to specific requirements without the burden of extensive tooling investments. This technology allows for the production of intricate geometries that were previously impossible or too expensive to achieve, unlocking new possibilities for performance enhancements and efficiency.

Moreover, 3D printing accelerates the prototyping phase significantly. Engineers can develop and test multiple iterations of a ball valve design in a fraction of the time it would take with conventional methods. This rapid prototyping not only shortens the development cycle but also fosters innovation, as manufacturers have the flexibility to experiment with new concepts and materials on-the-fly. As a result, they can respond more effectively to market demands, produce specialized valves for niche applications, and ensure that their products remain competitive in an ever-evolving landscape.

Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers - Utilizing 3D Printing for Customization and Rapid Prototyping

| Technology | Description | Benefits | Applications |

|---|---|---|---|

| 3D Printing | Additive manufacturing used for creating complex valve components. | Customization, reduced material waste, rapid prototyping. | Oil & Gas, Water Management, Chemical Processing. |

| IoT Integration | Smart valves equipped with sensors and connectivity for data collection. | Real-time monitoring, predictive maintenance, enhanced efficiency. | Smart Water Networks, Industrial Automation, HVAC Systems. |

| Computer-Aided Design (CAD) | Advanced software for designing and analyzing valve components. | Improved accuracy, faster design cycles, easy modifications. | Prototype Development, Product Customization, Performance Analysis. |

| Material Innovations | Development of advanced materials for better performance and durability. | Corrosion resistance, weight reduction, longer lifespan. | High-pressure applications, corrosive environments, extreme temperatures. |

| Simulation and Modeling | Using software to simulate valve performance under various conditions. | Risk mitigation, design validation, cost savings. | R&D, Quality Assurance, Performance Testing. |

Exploring Sustainable Practices in Ball Valve Manufacturing Innovations

The ball valve manufacturing industry is undergoing a transformative phase, with sustainable practices at the forefront of innovation. Numerous reports indicate that the global market for environmentally-friendly valve systems is projected to grow significantly, with a compound annual growth rate (CAGR) of over 5% from 2021 to 2026. This shift is largely driven by regulatory pressures and the increasing demand for energy-efficient products. Manufacturers are adopting new technologies such as advanced materials and eco-friendly coatings that not only enhance performance but also minimize environmental impact.

To implement sustainable practices effectively, companies should focus on lifecycle assessments to evaluate the environmental footprint of their products. Tips for manufacturers include investing in materials that are recyclable and reducing waste in production processes. Adopting automation and IoT technologies can further streamline operations, leading to reduced energy consumption and increased efficiency in manufacturing.

Moreover, integrating sustainable sourcing strategies is crucial for long-term viability. According to industry studies, around 70% of valve manufacturers are now prioritizing sustainable supply chains that emphasize the use of organic and low-impact materials. Embracing these innovations will not only contribute to the health of the planet but also meet the evolving expectations of environmentally-conscious consumers.

Related Posts

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Understanding the Importance of Control Valves in Modern Industrial Applications

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China