Top 10 Hydrogen Valves for Optimal Performance and Safety in Applications

In the rapidly evolving field of hydrogen technology, ensuring the performance and safety of hydrogen valves is paramount. As industries increasingly shift towards hydrogen as a clean energy source, the demand for high-quality, reliable hydrogen valves grows. Renowned expert Dr. Emily Carter, a leading figure in hydrogen energy systems, emphasizes this necessity, stating, “The integrity and efficiency of hydrogen valves are critical to the advancement of hydrogen applications, ensuring both optimal performance and safety across various sectors.”

As we approach 2025, understanding the top hydrogen valves on the market becomes essential for engineers and decision-makers alike. The efficient handling of hydrogen, whether in industrial applications or transportation, relies heavily on the right valve technologies. With safety concerns at the forefront, selecting the most reliable models will be crucial for mitigating risks associated with hydrogen’s flammability and volatility.

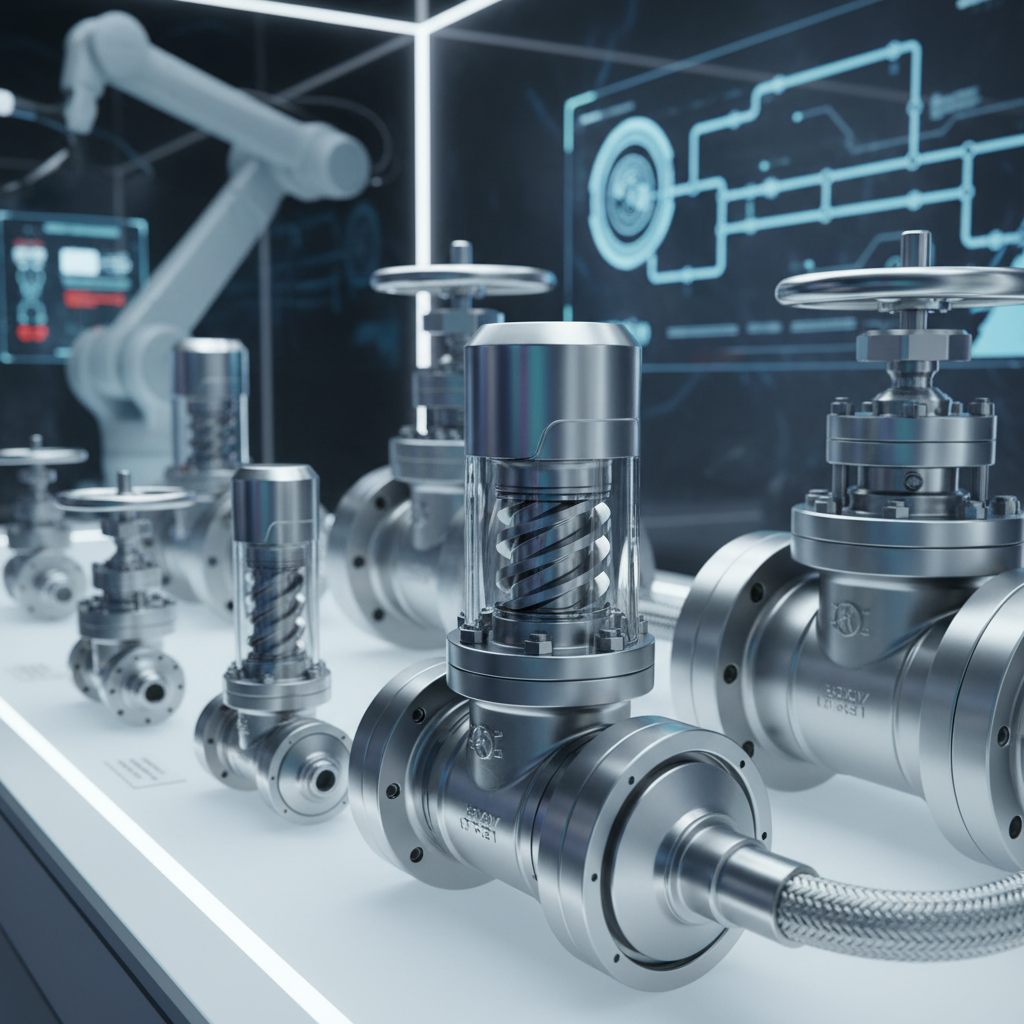

This article presents the "Top 10 Hydrogen Valves for Optimal Performance and Safety in Applications", providing an insightful overview of the leading solutions that meet industry standards. From innovative designs to robust materials, these valves not only enhance operational efficiency but also adhere to stringent safety regulations, setting the stage for a sustainable hydrogen future.

Top Trends Shaping the Hydrogen Valve Market in 2025

The hydrogen valve market is set to experience significant transformation by 2025, driven by a growing emphasis on safety, innovation, and sustainability. According to a recent market analysis by Research and Markets, the global hydrogen valve market is projected to reach USD 1.2 billion by 2026, growing at a CAGR of 8.5% from 2021. This growth is largely fueled by the rising investments in hydrogen energy initiatives, which underscore the need for reliable and high-performance valves that can withstand the unique challenges posed by hydrogen as a fuel source.

One of the key trends shaping this market is the increasing demand for lightweight and compact valve designs that enhance efficiency and reduce material costs. A report by Technavio highlights that advancements in materials, such as composite and corrosion-resistant alloys, are essential for developing valves capable of operating under high pressures and temperatures while ensuring leak-proof functionality. Additionally, the integration of smart technologies to monitor valve performance is becoming more prevalent, allowing operators to optimize system performance and improve safety protocols. As the hydrogen economy continues to gain traction, the imperative for cutting-edge valve solutions will become increasingly pronounced.

Key Features and Specifications for Performance in Hydrogen Applications

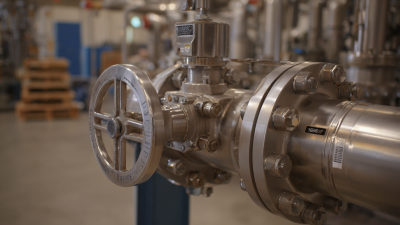

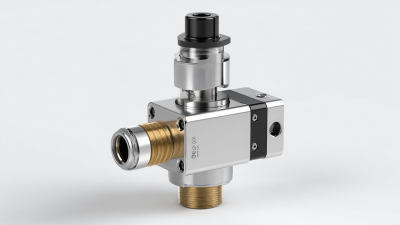

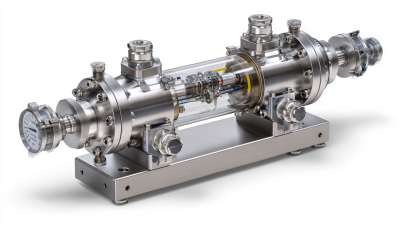

When selecting hydrogen valves for various applications, several key features and specifications play a crucial role in ensuring optimal performance and safety. First and foremost, materials must be compatible with hydrogen; valves constructed from stainless steel or specialized alloys help prevent hydrogen embrittlement, a common risk in high-pressure environments. Additionally, the design should incorporate leakage prevention mechanisms, such as double-sealed constructions, to mitigate the risks of leaks and ensure operational integrity.

Another critical specification is the valve's pressure rating, which must meet the demands of high-pressure hydrogen systems. Valves designed for a range of pressures can adapt to various applications, from industrial to laboratory settings. Furthermore, actuators, whether manual or automated, should provide precise control and rapid response times, ensuring that operations can be swiftly adjusted in response to changes in system conditions. Ultimately, focusing on these key features will lead to safer handling and improved performance in hydrogen applications.

Top 10 Hydrogen Valves Performance Metrics

Safety Standards and Regulations Governing Hydrogen Valve Usage

When discussing hydrogen valves, safety standards and regulations are paramount due to the unique challenges posed by hydrogen as a fuel source. According to a report by the Hydrogen Council, global hydrogen production is projected to reach 530 million tons by 2030. This rapid growth signals an urgent need for stringent safety protocols to mitigate risks associated with hydrogen's flammability and potential leakage, urging manufacturers to comply with standards such as ISO 14687 and the American National Standards Institute (ANSI) specifications.

Furthermore, the National Fire Protection Association (NFPA) has also established guidelines, specifically NFPA 2, which oversees the safe use of hydrogen technologies. This regulation emphasizes the importance of using appropriate materials and designs to prevent hydrogen embrittlement and ensure valve integrity under high pressure. Compliance with such guidelines not only enhances the performance and reliability of hydrogen valves but also reassures stakeholders about operational safety in various applications, from transportation to industrial processes.

As the demand for hydrogen solutions accelerates, adherence to these safety standards will be crucial for fostering innovation while safeguarding public and environmental health.

Comparative Analysis of the Leading Hydrogen Valve Brands in 2025

In 2025, the landscape of hydrogen valves has evolved significantly, with various brands competing to offer the best performance and safety for diverse applications. Each manufacturer has introduced innovative technologies aimed at enhancing the durability and efficiency of their valves. For example, some top contenders have focused on lightweight materials that not only reduce overall weight but also improve resistance to corrosion, which is crucial in hydrogen applications due to the gas's aggressive nature.

A comparative analysis of these leading brands reveals that while some prioritize cost-effectiveness, others emphasize high-end specifications tailored for specific industrial uses. Brands that have invested in advanced sealing technology showcase their commitment to preventing leaks, a vital factor in ensuring safety. Additionally, the integration of smart technologies, such as IoT capabilities for monitoring pressure and flow, has emerged as a critical differentiator among manufacturers. This trend towards smarter valves reflects the growing importance of automation and real-time data in industrial operations, setting the stage for the future of hydrogen handling systems.

Emerging Technologies Enhancing Hydrogen Valve Efficiency and Reliability

Emerging technologies are revolutionizing the design and functionality of hydrogen valves, enhancing their efficiency and reliability across various applications. Advanced materials, such as lightweight composites and corrosion-resistant alloys, are being utilized to improve the durability of valves under extreme conditions. These materials not only minimize wear and tear but also ensure the valves can withstand the high pressures associated with hydrogen storage and transport.

Moreover, innovations in smart technologies are being incorporated into hydrogen valve systems. The integration of IoT (Internet of Things) devices allows for real-time monitoring of valve performance, leading to predictive maintenance strategies that prevent failures before they occur. This proactive approach enhances safety measures while optimizing operational performance. Additionally, automated control systems enable precise regulation of hydrogen flows, resulting in reduced energy waste and improved overall efficiency in hydrogen applications. The synergy of these emerging technologies promises significant advancements in the reliability and effectiveness of hydrogen valves.

Related Posts

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

-

Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

-

Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers