Why Do You Need an Air Valve in Your System?

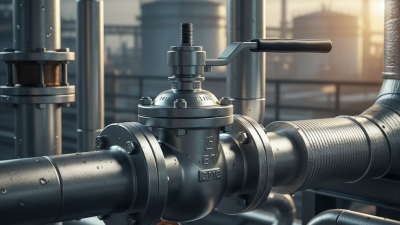

When designing a fluid system, ensuring proper airflow is crucial. An air valve plays a vital role in this process. It controls the entry and exit of air, maintaining optimal pressure and flow. Without it, systems may become inefficient. Air can accumulate, causing pressure fluctuations that damage equipment.

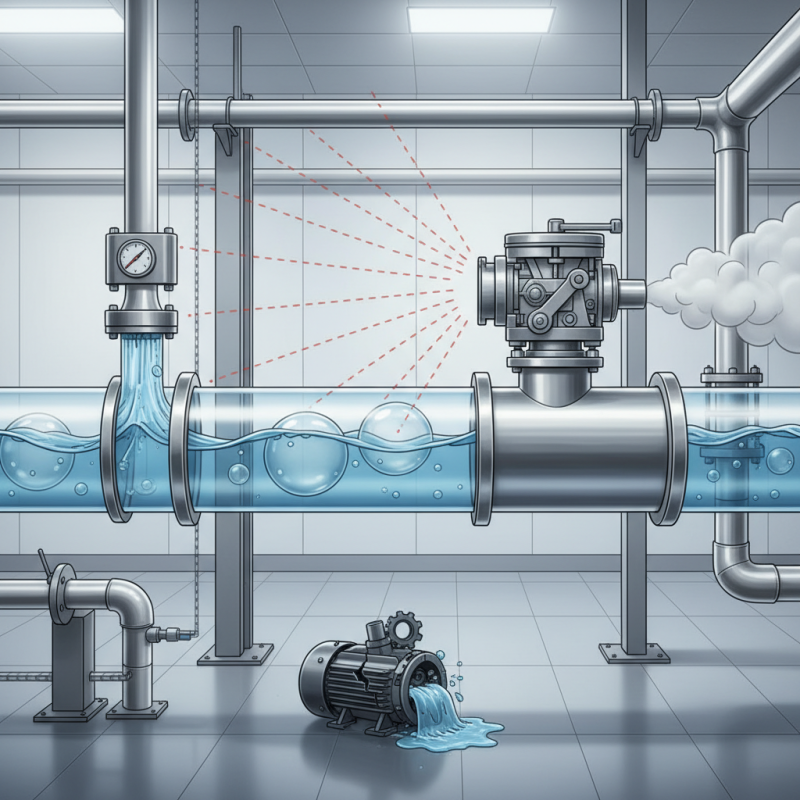

Imagine a pipeline filled with water. If air pockets form, they can disrupt the flow. This can lead to noise, vibration, and even system failure. The air valve prevents these issues by allowing trapped air to escape. It enhances the overall performance of your system.

Neglecting this component could lead to costly repairs. Sometimes, even experienced engineers overlook the importance of an air valve. It's easy to underestimate its significance until a problem arises. Recognizing its necessity is essential for any successful system design.

Understanding the Function of Air Valves in Systems

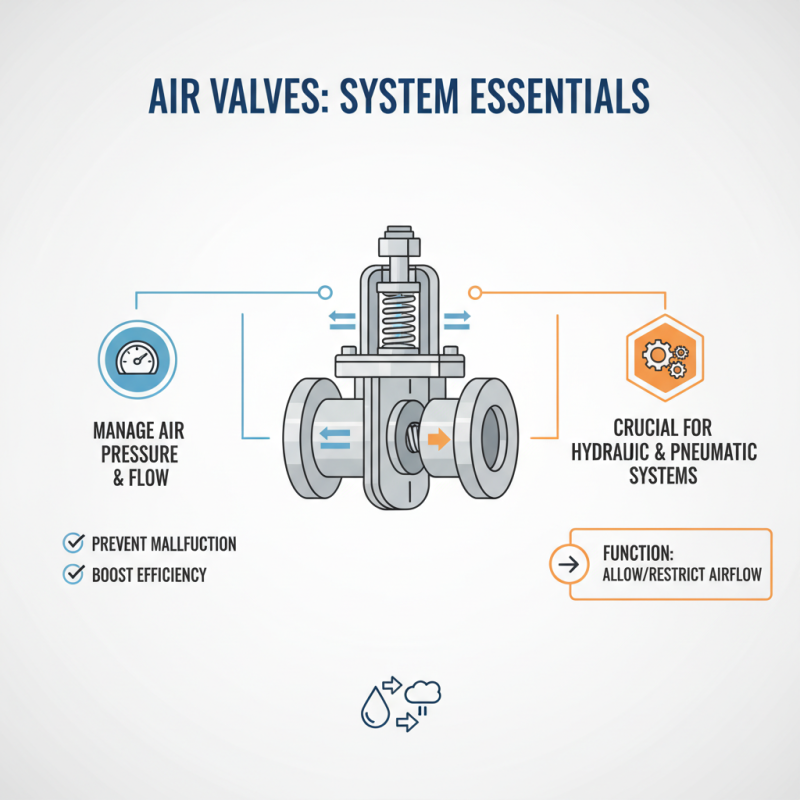

Air valves play a crucial role in various systems. They help manage air pressure and flow effectively. By doing so, they prevent issues like system malfunction or reduced efficiency. These valves are essential in hydraulic and pneumatic systems. Their primary function is to allow or restrict airflow when needed.

When air enters a system, it can create inconsistencies. The presence of trapped air can lead to disruptions. Air valves help eliminate excess air, ensuring smoother operation. They also prevent potential damage from air pockets. This minimizes the need for frequent maintenance and repairs.

Understanding air valves' functions can guide better system design. However, not all systems utilize them effectively. Some may overlook their importance, leading to problems over time. Recognizing these shortcomings can lead to improvements. Properly integrated air valves can enhance overall system reliability.

Different Types of Air Valves and Their Applications

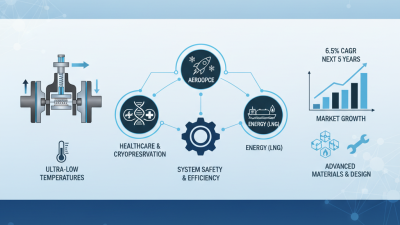

Air valves play a crucial role in various systems, ensuring efficient operation and safety. Different types serve specific purposes. For instance, air release valves are used in water distribution systems. They help eliminate trapped air, preventing pressure fluctuations. According to a report by the American Water Works Association, 70% of pipeline issues stem from air accumulation. This statistic highlights the importance of using air valves effectively.

Another common type is the air vacuum valve. These valves are vital for maintaining negative pressure in vacuum systems. They prevent air from entering and protect system integrity. A study published in the Journal of Hydraulic Engineering found that well-implemented air vacuum valves can reduce energy costs by up to 30%. This demonstrates the significant financial benefits these valves can offer.

However, not all air valves are created equal. Installation errors or improper sizing can lead to inefficiencies. Some systems might face operational challenges due to incorrect valve selection. This can cause not only performance issues but also increased maintenance costs. Keeping these factors in mind can improve overall system reliability and efficiency.

The Importance of Air Valves in Maintaining System Efficiency

Air valves play a crucial role in maintaining system efficiency. They help regulate air flow, which impacts pressure control significantly. In a study by the American Society of Mechanical Engineers, systems without proper air valves showed a 25% increase in operational costs. This is substantial for any facility aiming for cost efficiency.

Effective air valves minimize the risk of air entrainment and pressure drops. When accounting for maintenance, reports indicate that systems with malfunctioning valves can experience up to 30% lower performance. This means that regular checks are vital. A simple valve malfunction can lead to larger system inefficiencies.

However, many systems overlook the importance of air valves. Installation errors or improper sizing can occur. In fact, 40% of facility managers report inconsistent performance due to poorly functioning valves. Continuous monitoring can mitigate these issues. Investing in quality air valves is not just an option; it's a necessity for optimal system performance.

Why Do You Need an Air Valve in Your System? - The Importance of Air Valves in Maintaining System Efficiency

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Pressure Regulation | Maintains desired pressure levels within the system. | Enhances equipment lifespan and efficiency. | HVAC systems, industrial processes. |

| Air Flow Control | Regulates the flow of air to different parts of the system. | Prevents system overload and reduces energy consumption. | Pneumatic systems, manufacturing lines. |

| Air Release | Allows trapped air to escape from the system. | Reduces risk of cavitation and improves system reliability. | Water treatment facilities, hydraulic systems. |

| Safety Features | Built-in safety valves to prevent overpressure. | Ensures safe operation and reduces hazards. | Chemical processing, oil and gas industries. |

Common Issues Caused by Lack of Air Valves in Systems

Air valves play a crucial role in fluid systems by managing air and pressure effectively. Without proper air valves, several common issues can arise. One significant problem is air entrapment, which leads to inefficient system performance. According to industry reports, systems without air valves can experience a 30% reduction in efficiency due to trapped air. This inefficiency directly impacts operational costs and can lead to increased wear on system components.

Another issue is water hammer. This phenomenon occurs when there's a sudden change in flow, creating shock waves in the pipes. A study found that around 25% of reported pipeline failures relate to water hammer effects. Not only is this dangerous, but it can also result in costly repairs and downtime. The absence of air valves hampers the ability to absorb these shock waves, making systems more vulnerable.

Tips: Regularly inspect your air valves to ensure they are functioning properly. Pay attention to unusual noises in your system, as these can signal air-related issues. Maintaining proper ventilation can mitigate most of these concerns. Consider how air management strategies can dramatically improve the efficiency and safety of your system. Understanding the role of air valves is vital for effective system maintenance.

Best Practices for Selecting and Maintaining Air Valves

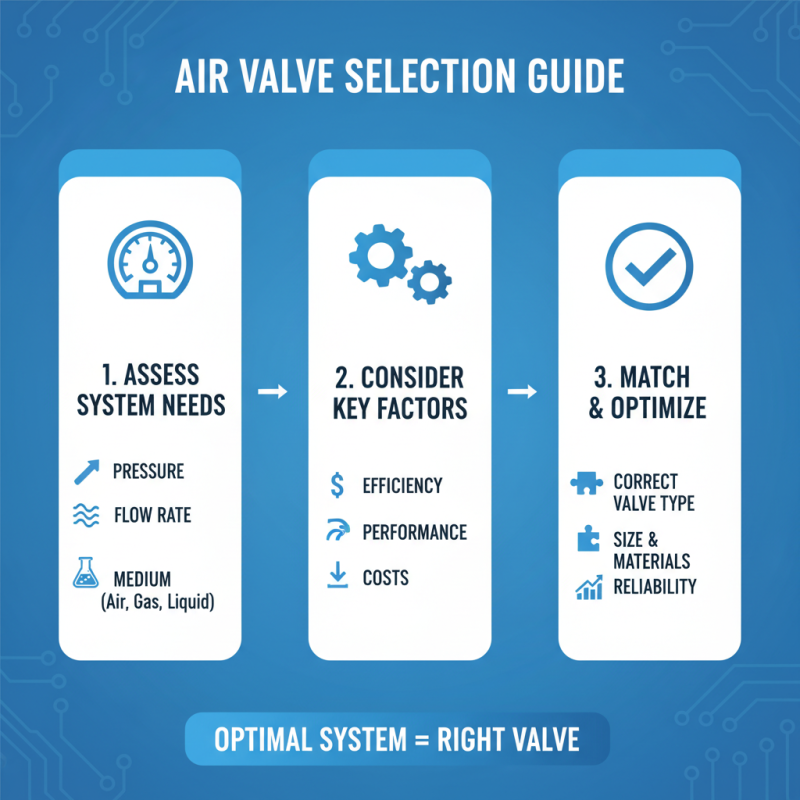

Selecting the right air valve is crucial for optimal system performance. Start by assessing the specific needs of your system. Consider factors like pressure requirements, flow rates, and the medium being controlled. A mismatch here can lead to inefficiencies and increased costs in operation.

Maintenance plays a key role in the longevity of air valves. Regular inspections are necessary. Look for leaks or signs of wear. Even minor issues can escalate quickly if ignored. It’s essential to address these problems promptly. Use appropriate lubricants as needed, but don’t overdo it. Too much friction-reducing agent can attract dirt and debris, causing further issues.

Training staff on proper handling and maintenance practices is vital. Many systems suffer from neglect due to a lack of understanding. Encourage questions and discussions to foster an environment of learning. Mistakes happen. Acknowledge them and learn from each instance. Even small oversights can lead to larger system failures down the line.

Related Posts

-

Top 10 Essential Valve Tags for Efficient Industrial Safety Management

-

Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers

-

Best Cryogenic Check Valves for Essential Applications in Cold Environments

-

Why Choosing Stainless Ball Valves is Essential for Your Industrial Applications

-

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

-

Top 10 Benefits of Using Flow Check Valves in Your Plumbing System