Understanding the Importance of Control Valves in Modern Industrial Applications

Control valves play a pivotal role in modern industrial applications, serving as the critical components that manage the flow and pressure of various fluids in process systems. According to a report by MarketsandMarkets, the global control valve market is projected to reach USD 6.72 billion by 2025, growing at a CAGR of 6.1% from 2020. This growth underscores the increasing reliance on control valves in sectors such as oil and gas, water and wastewater treatment, and power generation. As industries strive for enhanced efficiency and safety, the significance of precise control valve operation heightens, facilitating optimized process control and minimizing energy consumption. Understanding the principles and intricacies of control valve functionality is essential for professionals aiming to leverage these components to improve operational performance and achieve sustainable industrial practices.

The Role of Control Valves in Enhancing Process Efficiency in Industries

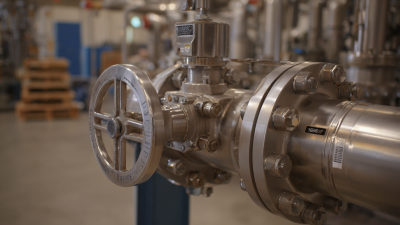

Control valves play a critical role in enhancing process efficiency across various industrial applications. By precisely regulating fluid flow, temperature, pressure, and other critical variables, these valves enable systems to operate at optimal performance levels. This not only conserves energy but also minimizes waste and reduces wear and tear on equipment. In industries such as chemical processing, oil and gas, and water treatment, control valves are essential for maintaining safe and efficient operations, allowing for better control of production processes.

Moreover, the integration of advanced control valve technologies, such as smart actuators and automated control systems, further boosts efficiency. These innovations facilitate real-time monitoring and adjustments, leading to improved response times and reduced downtime. In a competitive market where process optimization is crucial for profitability, the value of control valves cannot be overstated. Their ability to respond swiftly to changing conditions ensures that industries can maintain high productivity while adhering to safety and environmental regulations.

Understanding the Importance of Control Valves in Modern Industrial Applications

| Industry | Control Valve Type | Primary Function | Efficiency Improvement (%) | Common Applications |

|---|---|---|---|---|

| Oil & Gas | Globe Valve | Flow Regulation | 25 | Refining, Transportation |

| Water Treatment | Ball Valve | On/Off Control | 20 | Filtration, Distribution |

| Chemical Processing | Butterfly Valve | Flow Control | 30 | Mixing, Reaction |

| Power Generation | Pinch Valve | Flow Control for Slurries | 28 | Coal Handling, Biomass |

| Pharmaceuticals | Diaphragm Valve | Sterile Flow Control | 32 | Manufacturing, Packaging |

Key Performance Metrics for Control Valves: Understanding Flow Coefficients and Pressure Drops

Control valves play a vital role in modern industrial applications by regulating the flow and pressure of fluids within systems. Understanding key performance metrics, particularly flow coefficients (Cv) and pressure drops, is crucial for optimizing valve selection and ensuring efficiency in processes. The flow coefficient indicates the volume of fluid that can pass through a valve at a given pressure drop, serving as a fundamental parameter for designers and engineers. A high Cv indicates better flow capacity, which is advantageous for systems requiring rapid fluid handling.

Pressure drop, on the other hand, reflects the resistance encountered by the fluid as it moves through the valve, impacting overall system performance. A well-defined pressure drop is essential to maintain the desired flow rates and ensure effective operation. Designers must consider both the flow coefficients and pressure drops when selecting control valves to balance performance and energy consumption. By accurately assessing these metrics, industries can enhance process control, reduce energy costs, and improve the reliability of their operations, leading to greater efficiency and productivity in the long run.

Key Performance Metrics for Control Valves

This chart illustrates the flow coefficients (Cv) and pressure drops (ΔP) across different types of control valves, highlighting their significance in industrial applications.

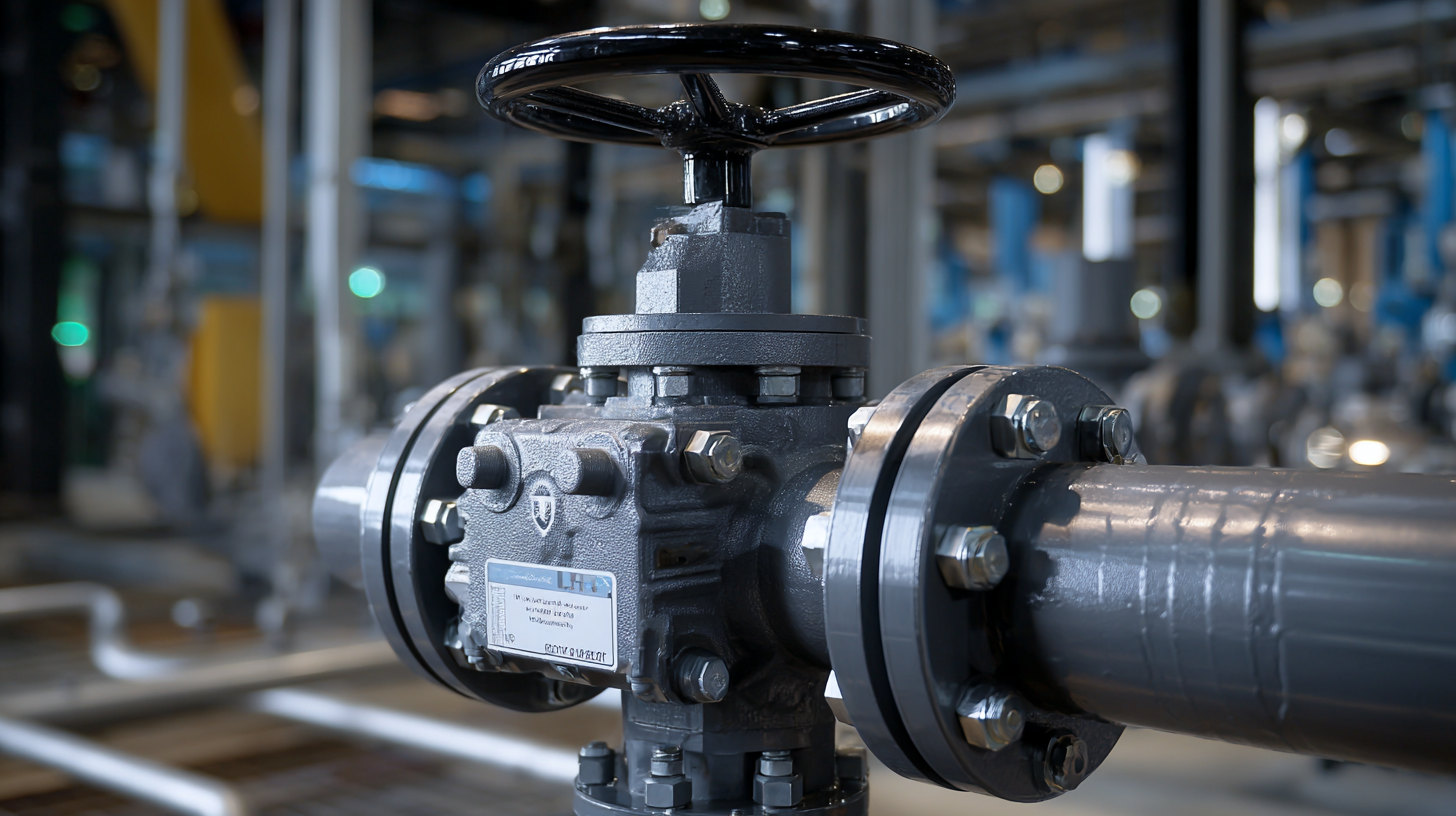

Common Types of Control Valves Used in Industrial Applications and Their Specifications

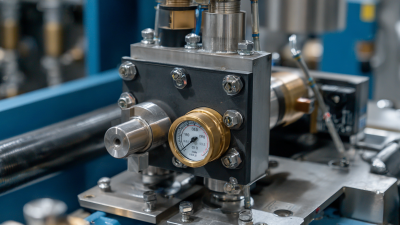

Control valves are vital components in modern industrial applications, serving to regulate the flow, pressure, and temperature of fluids in various systems. Among the common types, globe valves are frequently utilized for their efficient throttling capabilities, making them ideal for applications that require precise control. Typically, globe valves feature a spherical body shape that facilitates robust flow regulation, and they are available in different materials such as stainless steel or brass, which cater to specific fluid characteristics and temperature ranges.

Control valves are vital components in modern industrial applications, serving to regulate the flow, pressure, and temperature of fluids in various systems. Among the common types, globe valves are frequently utilized for their efficient throttling capabilities, making them ideal for applications that require precise control. Typically, globe valves feature a spherical body shape that facilitates robust flow regulation, and they are available in different materials such as stainless steel or brass, which cater to specific fluid characteristics and temperature ranges.

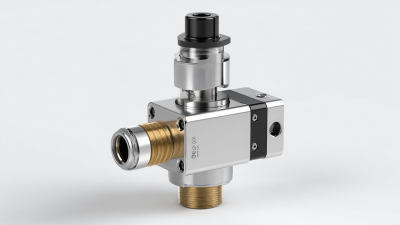

Another prevalent type is the ball valve, renowned for its quick shut-off capabilities. This design incorporates a spherical disc that rotates to control fluid flow, making it suitable for applications requiring rapid on/off operation. Ball valves are generally made from durable materials like metal or plastic, enabling them to withstand high pressures and temperatures. Additionally, care must be taken when selecting the appropriate size and specifications, including the valve's pressure rating and connection type, to ensure compatibility with the overall system requirements.

Impact of Control Valve Selection on Energy Consumption and Cost Savings in Manufacturing

Control valves play a crucial role in industrial processes, significantly impacting energy consumption and operational costs. A recent study by the International Society of Automation (ISA) found that improper control valve selection can lead to energy inefficiencies of up to 20% in manufacturing operations. Choosing the right valve not only enhances system performance but also contributes to substantial cost savings, with some companies reporting reductions in energy bills by as much as 30% following an upgrade to more efficient control valves.

When selecting control valves, it is essential to consider factors such as flow rate, pressure drop, and valve type. According to a 2022 report from the U.S. Department of Energy, optimizing control valve selection can lead to energy savings of around $10 billion annually across the manufacturing sector. A well-chosen control valve minimizes pressure losses and enhances regulation accuracy, thus reducing the overall energy needed for process systems.

**Tips:** Always consult with an expert for a thorough analysis of your system's needs before making control valve selections. Regular maintenance of existing valves can also ensure they operate at peak efficiency, thereby maximizing cost savings over time. Moreover, considering the installation of smart monitoring systems can provide real-time data, enabling further energy optimization.

Trends and Innovations in Control Valve Technology: Future Directions for the Industry

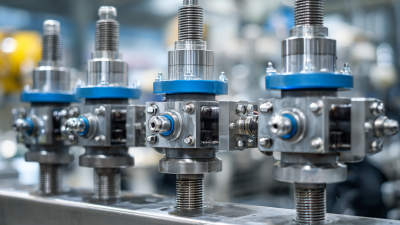

The landscape of control valve technology is rapidly evolving, driven by the demand for increased efficiency, reliability, and integration with smart technology. Industry trends indicate a growing focus on automation and IoT compatibility, allowing for real-time monitoring and predictive maintenance. These advancements not only enhance operational efficiency but also lead to significant cost savings through reduced downtime and improved resource management.

Tips: When selecting control valves for your application, consider the compatibility with existing systems and the ease of integration with IoT devices. This foresight can facilitate smoother transitions to automated processes, ensuring that your operations remain competitive.

Innovations such as advanced materials and design methodologies are also shaping the future of control valves. These developments enable manufacturers to produce valves that can withstand extreme conditions while maintaining precise control over flow rates. The incorporation of artificial intelligence in valve operation management offers predictive analytics, potentially reducing human error and optimizing performance.

Tips: Regularly assess the life cycle of your control valves and stay informed about the latest materials and technologies. Engaging with suppliers who prioritize innovation can provide you with cutting-edge solutions tailored to your specific needs.

Related Posts

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data