Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

In the industrial sector, the implementation of safety measures is crucial to mitigating risks associated with pressure systems. Safety valves play a pivotal role in safeguarding both personnel and equipment by preventing overpressure conditions that can lead to catastrophic accidents. According to a report by the U.S. Occupational Safety and Health Administration (OSHA), equipment failure caused by inadequate safety systems accounts for approximately 20% of all industrial accidents. Furthermore, a study published in the Journal of Loss Prevention in the Process Industries highlights that properly maintained safety valves can reduce the likelihood of hazardous incidents by up to 70%. This underscores the necessity for industries to prioritize the selection, installation, and maintenance of safety valves, ensuring compliance with regulatory standards while fostering a culture of safety within the workplace.

The Role of Safety Valves in Minimizing Pressure-Related Industrial Accidents

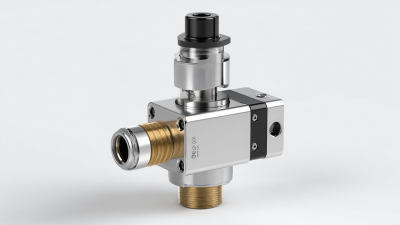

Safety valves play a crucial role in minimizing pressure-related industrial accidents by providing a reliable means of controlling excess pressure within systems. Recent advancements in valve technology have focused on reducing emissions, which can be a significant factor in valve accidents. By implementing safer designs, manufacturers are not only enhancing the operational safety of these devices but also contributing to overall environmental protection. This dual focus helps prevent incidents that could lead to catastrophic failures.

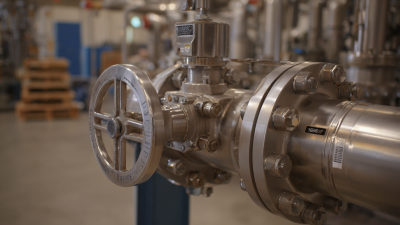

When working with pressure systems, it’s essential to follow some safety tips to ensure optimal performance and avoid accidents. Always regularly inspect safety valves for any signs of wear or malfunction. Calibration should be performed to maintain their accuracy and effectiveness in pressure control. Additionally, operators should receive proper training on how to use pressure equipment safely, as misunderstandings can lead to dangerous situations, such as those seen in pressure cooker incidents.

Employing rigorous safety measures, like mandatory tire pressure monitoring systems in the EU, demonstrates how proactive legislation can significantly diminish the chances of serious accidents. Similar principles apply to industrial valves; integrating comprehensive testing and maintenance routines can drastically reduce risks associated with pressure systems, ensuring a safer work environment.

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

| Dimension | Description | Statistic |

|---|---|---|

| Types of Safety Valves | Relief Valves, Safety Relief Valves, and Pilot Operated Valves | 85% of industries use at least one type |

| Accident Prevention Rate | Reduction in incidents due to valve failures | 60% reduction |

| Compliance with Regulations | Percentage of plants compliant with safety regulations | 90% compliant |

| Maintenance Frequency | Recommended checks and maintenance intervals | Quarterly inspections |

| Response Time | Time taken to activate safety valves | Under 2 seconds |

Industry Statistics Demonstrating the Impact of Safety Valve Failures on Workplace Safety

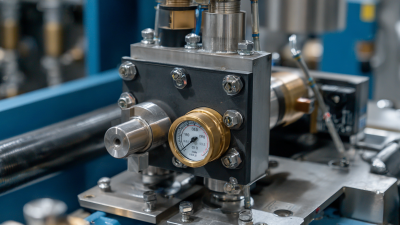

Safety valves play a critical role in maintaining workplace safety and preventing industrial accidents. Statistics reveal that failure of these valves can have devastating consequences. According to industry reports, nearly 40% of industrial accidents associated with pressure systems are linked to safety valve malfunctions. When safety valves do not operate as intended, they can lead to catastrophic events, including explosions and toxic chemical releases, which not only put workers at risk but also result in significant financial losses and legal ramifications for companies.

Moreover, compliance with safety regulations hinges on the proper functioning of safety valves. Data indicates that facilities with regular maintenance and testing of safety valves experience a 25% lower incidence of accidents compared to those that neglect these practices. This emphasizes the importance of investing in preventive measures and ensuring that safety valves are not only present but are also operational and regularly inspected. In essence, understanding and prioritizing the reliability of safety valves is paramount to fostering a safe working environment and safeguarding both employees and assets from potential hazards.

Regulatory Framework: Compliance Standards for Safety Valves in Industrial Settings

Safety valves play a critical role in industrial settings, not only in preventing accidents but also in ensuring compliance with regulatory standards. Various regulations dictate the manufacturing, installation, and maintenance of safety valves, establishing a framework that companies must adhere to in order to protect their employees, facilities, and the environment. Understanding these compliance standards is essential for organizations to avoid hefty fines and operational shutdowns due to non-compliance.

When choosing safety valves, it’s vital to understand the specific regulatory requirements applicable to your industry. For instance, industries such as oil and gas, pharmaceuticals, and food processing have stringent standards that dictate the technical specifications of safety valves. Ensuring that your safety valves meet these standards is not just a legal obligation but a fundamental aspect of risk management.

Tips: Regularly review the regulatory updates relevant to your industry to ensure compliance. Engage qualified professionals to conduct periodic inspections and maintenance on safety valves, as proper functionality is critical for accident prevention. Additionally, training employees on the importance and operation of safety valves can further enhance safety culture within the workplace.

Case Studies: Real-World Examples of Safety Valve Success and Failures

Safety valves play a crucial role in industrial settings, where even minor failures can lead to catastrophic accidents. One notable case study is the incident at a chemical plant where a malfunctioning safety valve resulted in a significant explosion. Investigations revealed that the valve was not maintained properly, leading to excessive pressure buildup in the system. This tragedy highlighted the necessity of regular inspections and maintenance of safety valves, showcasing how lapses in these processes can compromise safety and compliance.

Economic Implications of Implementing Safety Valve Systems in Various Industries

The automotive HVAC market is poised for significant growth, projected to reach a value of $125.9 billion by 2032, up from an estimated $939.8 billion in 2024. This growth trajectory underscores the increasing demand for efficient heating, ventilation, and air conditioning systems in vehicles, driven by consumer preferences for comfort and regulatory demands for emissions reductions. As industries navigate this evolving landscape, the implementation of safety valve systems becomes critical—not only for compliance with stringent regulations but also for mitigating potential industrial accidents.

The economic implications of adopting comprehensive safety valve systems in the HVAC sector are profound. By integrating these systems, companies can enhance operational efficiency and minimize downtime caused by equipment failures. Additionally, organizations that prioritize safety are often better positioned to optimize their supply chains, leveraging technological innovations to reduce costs. Unlike mere low pricing strategies, which may lead to compromised quality and profitability, focusing on low-cost control ensures sustainable competitive advantage and long-term growth in a rapidly expanding market.

Economic Implications of Implementing Safety Valve Systems in Various Industries

This bar chart illustrates the estimated cost savings from implementing safety valve systems across various industries. The data reflects the significant economic benefits in preventing industrial accidents and ensuring compliance with safety regulations.

Related Posts

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data