Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

The upcoming 2025 China Import and Export Fair, also known as the 138th Canton Fair, presents a unique opportunity to explore the innovative trends in the realm of low pressure relief valves. As industries worldwide increasingly prioritize safety and efficiency in their operations, the significance of low pressure relief valves cannot be overstated. These essential components play a critical role in protecting equipment and maintaining optimal performance by releasing excess pressure in various systems. This year’s fair will showcase cutting-edge designs and technologies that enhance the functionality and reliability of low pressure relief valves, addressing the evolving needs of diverse sectors. Attendees will have the chance to engage with industry leaders and discover the latest advancements that promise to revolutionize pressure management solutions in the global market.

Emerging Technologies in Low Pressure Relief Valve Design and Manufacturing

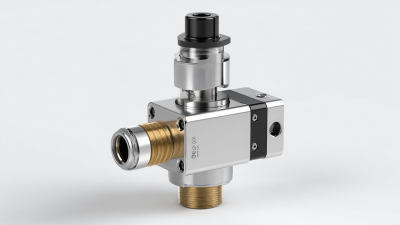

The upcoming 2025 China Import and Export Fair is set to showcase groundbreaking advancements in low pressure relief valve design and manufacturing. Recent trends indicate that the market for low pressure relief valves is expected to grow at a CAGR of 5.4% between 2023 and 2028, driven by advancements in materials and technology. Emerging technologies, such as smart valve systems integrated with IoT capabilities, are revolutionizing how these devices operate and maintain safety standards in industries like oil and gas, chemical processing, and water management.

In addition to IoT integration, manufacturers are increasingly adopting additive manufacturing techniques, allowing for rapid prototyping and customization of low pressure relief valves. A report by MarketsandMarkets forecasts that the global smart valve market will reach USD 7.1 billion by 2026, highlighting the increasing adoption of automation and smart systems. The focus on sustainability is also pushing manufacturers to utilize eco-friendly materials that can withstand aggressive chemicals while reducing environmental impact. These innovations not only enhance the efficiency and reliability of low pressure relief valves but also align with global trends towards sustainability and smart industry practices.

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

Key Market Trends Impacting Low Pressure Relief Valve Innovation

The low pressure relief valve market is experiencing a transformative shift, driven by several key trends that are reshaping innovation in this essential industry. One of the most significant trends is the adoption of advanced materials and manufacturing processes, which enhance the durability and efficiency of these valves. Emerging technologies such as 3D printing and enhanced metal alloys are allowing manufacturers to design more compact and lightweight valves while maintaining their reliability and performance under varying pressure conditions. This shift not only optimizes operational efficiency but also reduces the overall environmental footprint of valve production.

Another critical market trend is the increasing demand for smart technologies in industrial applications. The integration of IoT (Internet of Things) features into low pressure relief valves enables real-time monitoring and predictive maintenance, which can significantly reduce operational downtime. By leveraging data analytics, companies can gain insights into valve performance, leading to improved safety and cost management. This trend towards automation and smart technology is a crucial factor driving innovation, reflecting a broader move toward digital transformation across the manufacturing sector. These trends are set to prominently feature at the upcoming 2025 China Import and Export Fair, showcasing the future of low pressure relief valve technology.

Sustainability in Low Pressure Relief Valve Production: Challenges and Solutions

As the 2025 China Import and Export Fair approaches, the focus on sustainability in the production of low pressure relief valves is becoming increasingly paramount. Manufacturers are facing significant challenges in aligning their production processes with environmentally friendly practices. For instance, sourcing raw materials that are both high-quality and sustainable can be daunting, especially in a market driven by cost-efficiency. Additionally, there is pressure to minimize waste and reduce the carbon footprint associated with manufacturing operations.

To address these challenges, innovative solutions are being explored. The integration of advanced technologies, such as automation and smart manufacturing, can enhance production efficiency, thereby reducing resource consumption. Furthermore, manufacturers are investing in research to develop biodegradable materials and recycle existing products, which contribute to a circular economy. Collaborations among industrial stakeholders, including suppliers and technology providers, are crucial in fostering sustainable practices and ensuring that low pressure relief valves not only meet regulatory standards but also align with global environmental goals.

Comparison of Global Low Pressure Relief Valve Standards and Regulations

The global standards and regulations governing low pressure relief valves play a crucial role in ensuring safety and efficiency across various industries. During the 2025 China Import and Export Fair, comparisons of these standards highlighted the differences and similarities among international regulations. Various regions, including North America, Europe, and Asia, each have distinctive requirements that manufacturers must navigate. For instance, the American Society of Mechanical Engineers (ASME) offers rigorous specifications that differ significantly from the European Pressure Equipment Directive (PED). These variances reflect different approaches to safety and performance, making compliance a complicated yet vital aspect for exporters.

Furthermore, emerging trends in innovation within low pressure relief valves are increasingly shaping these standards. With advancements in materials and technology, new designs are being formulated that not only meet existing regulations but also propose enhanced performance metrics. The fair showcased how industry leaders are advocating for harmonization of standards to facilitate easier international trade. By aligning on key requirements, manufacturers can not only simplify their design and production processes but also ensure that their offerings meet the evolving safety expectations of the global market. This collaborative approach could lead to a significant transformation in the industry’s regulatory landscape, providing a more unified framework for low pressure relief valve standards internationally.

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

| Standard/Regulation | Region | Test Pressure (psi) | Material Standards | Certification Required |

|---|---|---|---|---|

| ASME Section VIII | USA | 15-300 | ASTM A216, A350 | Yes |

| API 520/521 | USA | 20-600 | Austenitic Stainless Steel | Yes |

| EN 4126 | Europe | 10-500 | Carbon Steel, Alloy Steel | Yes |

| GB 150 | China | 16-400 | Q235, Q345 | Yes |

| JIS B 2002 | Japan | 50-600 | SUS304, SUS316 | Yes |

Future Prospects: The Role of AI and IoT in Low Pressure Relief Valve Functionality

As the industry gears up for the 2025 China Import and Export Fair, the integration of artificial intelligence (AI) and the Internet of Things (IoT) in low pressure relief valves stands out as a pivotal trend. Leveraging AI technology allows for enhanced predictive maintenance, ensuring that these critical components operate efficiently and reliably. According to market research, the global smart valve market is projected to reach $7.06 billion by 2025, driven by advancements in IoT integration and AI capabilities. This indicates a strong inclination towards intelligent systems that enable real-time monitoring and data analysis.

Additionally, IoT-enabled low pressure relief valves can optimize safety and performance in various applications, from chemical processing to water management. A recent report highlights that implementing smart control systems can reduce operational costs by up to 30%. Through continuous data collection and analysis, these systems can identify potential failure points, significantly improving response times and operational safety. This innovative approach not only enhances functionality but also aligns with the growing demand for smart infrastructure solutions across industries, paving the way for a smarter and more efficient future.