Understanding the Importance of Relief Valves in Modern Industrial Applications

In modern industrial applications, the significance of relief valves cannot be overstated. Relief valves are critical safety devices designed to prevent excessive pressure buildup in various systems, ensuring operational integrity and safeguarding against potential hazards. According to a report by the American Society of Mechanical Engineers (ASME), improper management of pressure can lead to catastrophic failures, resulting in significant financial losses and jeopardizing worker safety. The global relief valve market, projected to reach USD 3.4 billion by 2025, underscores the increasing recognition of these components in industrial processes. As industries evolve and the complexity of operations increases, the demand for efficient and reliable relief valves is paramount. This article delves into the mechanics, types, and applications of relief valves, highlighting their crucial role in maintaining safety and efficiency in contemporary industrial settings.

The Critical Role of Relief Valves in Safety and Efficiency

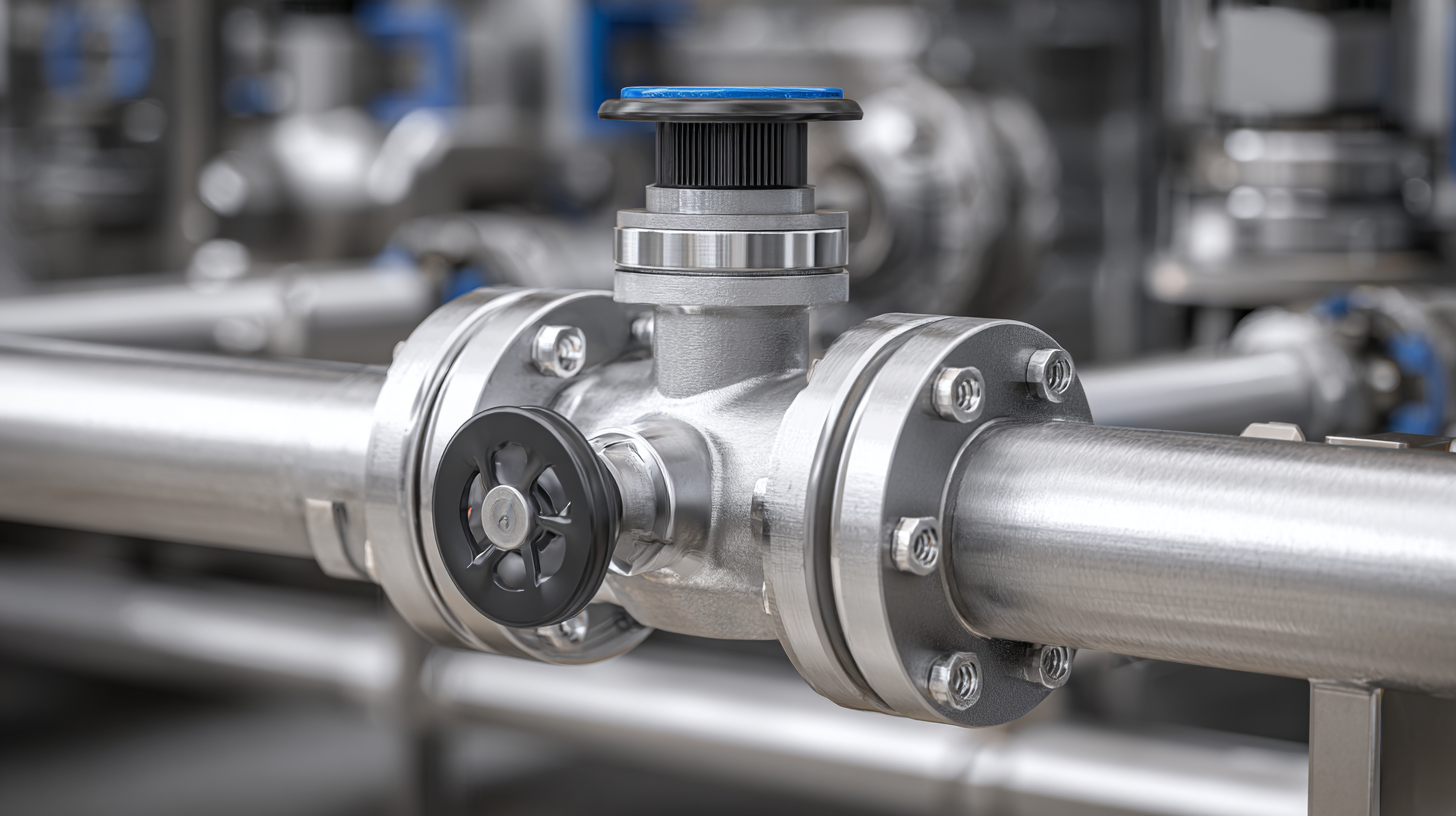

Relief valves play a crucial role in maintaining safety and efficiency in modern industrial applications, serving as a vital line of defense against overpressure situations. These valves are designed to automatically release excess pressure from systems, preventing catastrophic failures and protecting both equipment and personnel. For industries that handle pressurized fluids and gases, such as oil and gas, pharmaceuticals, and manufacturing, the importance of a reliable relief valve cannot be overstated. By ensuring that pressure levels remain within safe limits, these valves help to mitigate the risks of explosions, toxic leaks, and other dangerous incidents.

In addition to their safety benefits, relief valves contribute significantly to operational efficiency. By preventing pressure buildup, these devices maintain optimal functioning conditions for industrial processes, which can enhance productivity and prolong equipment life. Regular maintenance and proper selection of relief valves tailored to specific operational requirements can lead to a significant reduction in downtime and maintenance costs. As industries continue to face stringent regulations and the necessity for sustainable practices, understanding the role of relief valves becomes essential for achieving not only compliance but also the overall resilience of industrial operations.

Key Types of Relief Valves Used in Industrial Settings

Relief valves play a critical role in maintaining safety and efficiency in industrial applications. Various types of relief valves are utilized, each tailored to specific requirements. The most common types include pressure relief valves, vacuum relief valves, and temperature relief valves. According to a report by the -National Fire Protection Association (NFPA), over 60% of industrial accidents can be traced back to equipment overpressure, highlighting the need for effective pressure management tools.

Relief valves play a critical role in maintaining safety and efficiency in industrial applications. Various types of relief valves are utilized, each tailored to specific requirements. The most common types include pressure relief valves, vacuum relief valves, and temperature relief valves. According to a report by the -National Fire Protection Association (NFPA), over 60% of industrial accidents can be traced back to equipment overpressure, highlighting the need for effective pressure management tools.

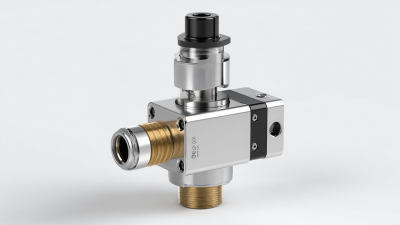

Pressure relief valves are designed to release excess pressure, preventing equipment failure and potential hazards. These valves are crucial in systems such as boilers and chemical processing plants. Vacuum relief valves, on the other hand, are essential in preventing vacuum conditions that can lead to tank implosion. In fact, the American Society of Mechanical Engineers (ASME) estimates that proper installation of these valves can reduce operational risks by up to 40%.

Tip: Regular maintenance and testing of relief valves are vital. Ensure valves are not only installed correctly but also subjected to routine inspections to ensure their functionality. This proactive approach can significantly mitigate risks and enhance operational efficiency. Additionally, understanding the specific application and environment of each valve type will aid in selecting the most effective solution for your industrial needs.

How to Select the Right Relief Valve for Your Application

Choosing the right relief valve for your industrial application is crucial for ensuring safety, efficiency, and compliance with regulatory standards. According to a report by the Pressure Relief Valve Manufacturers Association (PRVMA), improper selection can lead to significant operational risks, including equipment failure and hazardous situations. When selecting a relief valve, factors such as pressure rating, flow capacity, and the nature of the media being handled must be carefully considered. For instance, a valve designed for gas service may not perform adequately in liquid applications, which could result in severe consequences.

Additionally, it is essential to consider the operational environment and maintenance requirements. A study by the National Board of Boiler and Pressure Vessel Inspectors indicated that nearly 20% of relief valve failures are attributed to maintenance neglect. Therefore, selecting valves with materials that offer resistance to corrosion and wear, along with easy accessibility for maintenance, can enhance their reliability and longevity. Utilizing software tools and consulting experienced professionals can further assist in identifying the most suitable relief valve for your specific requirements, ensuring that you meet all safety and performance benchmarks.

Understanding the Importance of Relief Valves in Modern Industrial Applications

| Parameter | Value | Unit |

|---|---|---|

| Set Pressure | 150 | psi |

| Flow Rate | 500 | GPM |

| Material | Stainless Steel | N/A |

| Operating Temperature | 200 | °F |

| Application Type | Chemical Processing | N/A |

Common Challenges in Relief Valve Maintenance and Operation

Relief valves play a crucial role in maintaining safety and efficiency in various industrial applications, but their maintenance and operation come with a set of challenges. One common issue is the

accumulation of debris and deposits, which can impede the valve's ability to function correctly. According to a report by the American Society of Mechanical Engineers (ASME), nearly

30% of valve failures in critical systems are attributed to inadequate maintenance practices. Regular inspection and cleaning protocols are vital to prevent such failures and ensure optimal performance.

Relief valves play a crucial role in maintaining safety and efficiency in various industrial applications, but their maintenance and operation come with a set of challenges. One common issue is the

accumulation of debris and deposits, which can impede the valve's ability to function correctly. According to a report by the American Society of Mechanical Engineers (ASME), nearly

30% of valve failures in critical systems are attributed to inadequate maintenance practices. Regular inspection and cleaning protocols are vital to prevent such failures and ensure optimal performance.

Another significant challenge is the calibration of relief valves to meet specific operational parameters. Inaccurate settings can lead to either premature valve opening or failure to open under pressure, risking catastrophic events. A study published by the International Journal of Pressure Vessel and Piping highlighted that up to 20% of industrial incidents could be linked to improperly maintained or calibrated relief valves. This emphasizes the need for rigorous testing and recalibration schedules, especially in high-stakes environments such as chemical processing plants and oil refineries where pressure levels are constantly fluctuating.

Future Trends in Relief Valve Technology for Industry

Relief valves play a critical role in modern industrial applications, ensuring system safety and operational efficiency. As industries evolve, so does the technology behind these essential components. Future trends indicate a significant shift toward enhanced smart relief valve systems, which leverage the Internet of Things (IoT) and advanced process simulation software. These innovations not only facilitate real-time monitoring and remote operation but also contribute to predictive maintenance strategies, minimizing downtime and optimizing performance in various industrial sectors.

Tips: When selecting relief valves, consider integrating smart sensors that provide data analytics for improved decision-making. This can enhance your system's reliability and responsiveness, especially in complex environments like petrochemical processes.

Additionally, the projected growth of the hydraulic pressure relief valve market illustrates the increasing demand for advanced solutions that address efficiency and safety concerns. As industries push for cost reductions and enhanced effectiveness, investing in sophisticated valve technology will become paramount. Companies should stay abreast of these trends to leverage them for competitive advantage and compliance with evolving industry standards.

Related Posts

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair