Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

In the realm of industrial applications, the significance of cryogenic valves cannot be overstated. These specialized valves are crucial for the safe and efficient handling of ultra-low temperature fluids, including liquefied gases. According to Dr. Emily Carter, a leading expert in cryogenic systems, "Understanding the science behind cryogenic valves is essential for ensuring both operational safety and performance efficiency." Her insights highlight the importance of unlocking the intricate mechanisms that govern these vital components.

As industries increasingly rely on cryogenic technology for applications such as LNG transport and space exploration, the demand for reliable, high-performance cryogenic valves has surged. The operation of these valves must be foolproof, as even minor failures can lead to catastrophic consequences. This article aims to provide essential insights into the design, operation, and maintenance of cryogenic valves, ensuring that engineers and operators are well-equipped to handle the challenges posed by these extreme environments.

By delving into the science behind cryogenic valves, we aim to illuminate best practices for their safe operation, shedding light on common pitfalls and the latest innovations in valve technology. Join us as we explore this fascinating field and empower stakeholders to enhance safety and efficiency in their cryogenic operations.

Understanding Cryogenic Valves: Their Role in Safety and Efficiency

Cryogenic valves play a crucial role in industries that handle liquefied gases at extremely low temperatures, such as the aerospace, medical, and energy sectors. Understanding the unique properties of these valves is essential for ensuring both safety and efficiency in operations. Cryogenic temperatures can cause materials to behave differently; therefore, selecting the right valve materials and designs is vital to prevent failures that could lead to leaks or catastrophic incidents. Engineers must consider thermal contraction, material brittleness, and seal integrity when designing cryogenic systems.

In addition to safety concerns, cryogenic valves also improve the efficiency of gas handling processes. Properly functioning valves regulate the flow of liquid gases, allowing for precise control of pressure and temperature in storage and transfer systems. This efficiency not only minimizes waste but also optimizes energy consumption, making these valves integral to cost-effective operations. By investing in understanding and maintaining cryogenic valves, industries can ensure that their systems operate smoothly, safely, and efficiently, further enhancing their overall performance and safety standards.

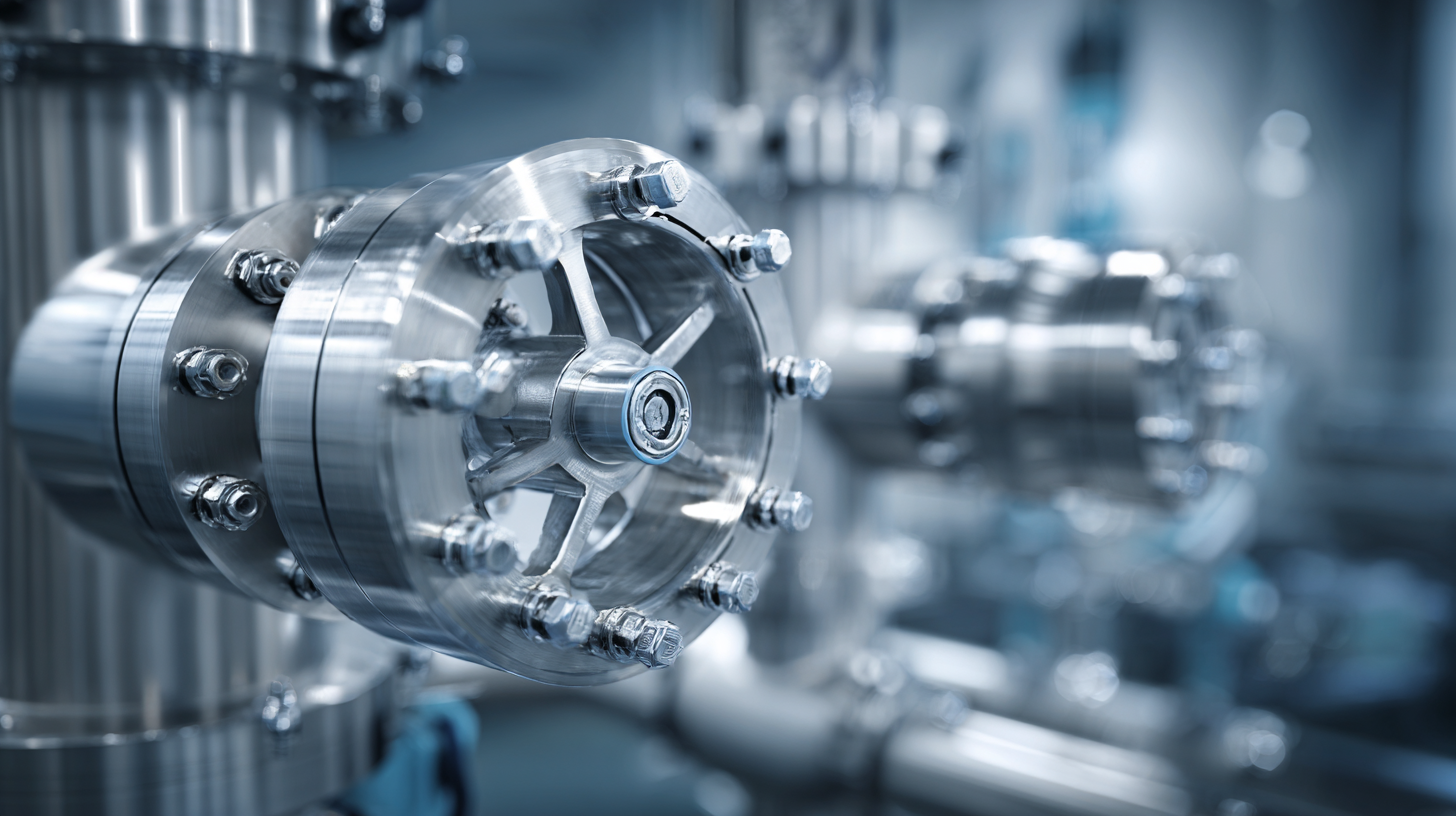

Key Components of Cryogenic Valves: Design and Functionality Explained

Cryogenic valves are essential for the safe and efficient handling of liquefied gases at extremely low temperatures, often below -150°C. Understanding their key components and functionalities is crucial for industries such as liquefied natural gas (LNG) and aerospace. A recent industry report indicates that the global cryogenic valve market is projected to reach USD 4.61 billion by 2026, growing at a CAGR of 7.8%. This growth underscores the importance of sophisticated design and reliability in cryogenic valve systems.

The primary components of cryogenic valves include the body, actuator, packing, and seats, each designed to maintain integrity under sub-zero conditions. For instance, the use of stainless steel, often complemented with specialized coatings, ensures durability against thermal stresses. Additionally, the seats are typically made from high-performance elastomers or thermoplastics that can withstand the rigorous demands of cryogenic environments. The functionality of these valves is generally categorized into two types: on-off valves, which control flow, and control valves, which regulate flow rate and pressure. According to a study by MarketsandMarkets, the demand for control cryogenic valves is rising, driven by advancements in automation technologies and increasing safety standards in handling cryogenic applications.

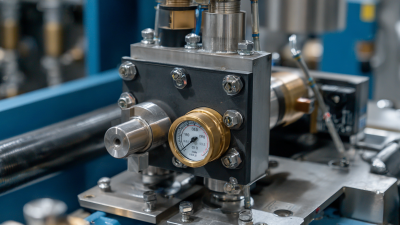

Common Challenges in Cryogenic Valve Operation and How to Address Them

Cryogenic valves play a crucial role in managing extremely low temperatures in applications like LNG and industrial gas systems. However, they come with operational challenges that need to be addressed to ensure safety and efficiency. One of the most common issues is the risk of freezing, which can occur due to moisture in the valve seat or stem. According to a report by the International Cryogenic Engineering Committee, nearly 30% of valve failures in cryogenic systems are attributed to freezing issues.

To mitigate these challenges, regularly maintaining the valves and inspecting seals and gaskets for wear is essential. Operators should implement a routine testing schedule, aligning with best practices suggested by the Cryogenic Society of America, which emphasizes the importance of preventative maintenance in reducing downtime and extending valve life.

**Tip:** Always monitor the ambient conditions and ensure that cryogenic valves are insulated properly. This minimizes the risk of external condensation which can lead to freezing.

Another challenge is the thermal expansion of materials, which can cause misalignment or leakage. Selecting materials with appropriate thermal coefficients based on the specific application is critical. Recent studies indicate that using advanced composite materials can significantly improve performance and reduce leakage rates by up to 15%.

**Tip:** Invest in training for your maintenance team to recognize early signs of material fatigue. A well-informed team is key to preventing costly unplanned shutdowns.

Common Challenges in Cryogenic Valve Operation

Best Practices for Maintaining Cryogenic Valves for Optimal Performance

Maintaining cryogenic valves is critical for ensuring their optimal performance in high-stakes environments such as LNG facilities or space applications. One key best practice is regular inspection and testing of the valves to identify any wear or damage that could compromise safety. Implementing a routine maintenance schedule that includes visual checks and functionality tests can help preemptively address potential failures. Proper lubrication of moving parts is also vital; using cryogenic-grade lubricants can significantly enhance the valve's reliability and lifespan.

Another important aspect of maintenance involves monitoring the operating conditions to ensure that they remain within specified limits. Extreme temperatures and pressures can cause material fatigue and other issues that may impair valve efficiency. Operators should also be trained in the unique characteristics of cryogenic systems, as misunderstandings can lead to mishandling during maintenance. By adhering to these best practices, organizations can not only prolong the life of their cryogenic valves but also enhance overall safety and operational effectiveness in their facilities.

Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

| Parameter | Description | Best Practice |

|---|---|---|

| Temperature Range | Typical operational range of cryogenic valves. | Regularly monitor ambient and operational temperatures. |

| Material Selection | Materials that withstand low temperatures and prevent leakage. | Conduct thorough material compatibility assessments. |

| Maintenance Schedule | Regular inspections and servicing of valves. | Establish and follow a strict maintenance routine. |

| Leak Detection | Methods for detecting gas leaks in cryogenic systems. | Implement regular leak testing using approved techniques. |

| Safety Training | Training programs for personnel managing cryogenic systems. | Conduct frequent safety training and emergency drills. |

Innovations in Cryogenic Valve Technology for Enhanced Safety Risks

Innovations in cryogenic valve technology are pivotal in addressing the safety risks associated with the handling of extremely low-temperature fluids. Advances in materials science have enabled the development of valves that not only withstand the harsh conditions of cryogenic environments but also enhance their operational reliability. For instance, the use of specialized alloys and coatings can minimize brittleness while preventing leaks, which are critical for systems dealing with liquefied gases like nitrogen and helium.

Furthermore, modern cryogenic valves are increasingly equipped with smart technologies that monitor their performance in real-time. These features allow for proactive maintenance and immediate detection of anomalies, significantly reducing the risk of catastrophic failures. Enhanced automation and control systems enable more precise regulation of flow and pressure, contributing to safer operational practices. As the industry pushes towards more efficient and secure cryogenic processes, these technological innovations serve as essential tools for ensuring safety and reliability in various applications, from aerospace to medical equipment.

Related Posts

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers