2026 How to Select the Right Cryogenic Check Valve for Your Applications?

Selecting the right cryogenic check valve is crucial for optimal performance in various applications. Expert Linda Harrow, a leading authority in cryogenic systems, states, "A proper check valve can make or break the efficiency of your setup." Her insights shed light on the importance of choosing the right valve to prevent reverse flow and ensure system integrity.

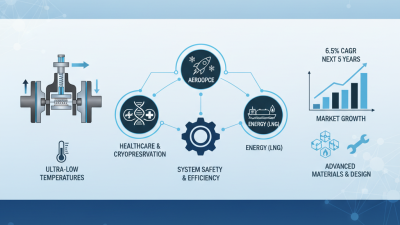

Cryogenic check valves operate under extreme conditions. These valves are essential in industries like LNG and aerospace. When temperatures drop, material selection becomes critical. Choosing the wrong valve material could lead to failure. Many overlook this aspect. The consequences can be costly, both financially and operationally.

Understanding the specific requirements of your application is vital. Factors such as pressure drop and flow rate must be evaluated. This is where many engineers struggle. A miscalculation can lead to suboptimal performance. Thus, a thoughtful selection process is essential. Investing time in research will ultimately yield better results in cryogenic applications.

Understanding the Basics of Cryogenic Check Valves

Cryogenic check valves are crucial components in many industrial applications. They prevent backflow in systems transporting cryogenic fluids. Understanding their function is essential for optimizing efficiency and safety. These valves operate at extremely low temperatures, often below -150°C. Material selection is vital, as materials must withstand these conditions without compromising structural integrity.

Tip: Always consider the temperature ratings of materials. Use valves made from stainless steel, bronze, or special alloys for durability.

Proper sizing is another key factor. The valve should match the pipe diameter and expected flow conditions. Oversized valves can lead to poor performance. A common mistake is neglecting to account for the specific pressures in your application. Check valve specifications should align with your system's requirements to prevent failures.

Tip: Confirm the pressure drop across the valve in your system. This can reveal potential issues before installation.

Regular maintenance is necessary for cryogenic systems. Valves should be inspected often. Look for signs of wear or damage. Neglecting this step can lead to significant downtime. An overlooked detail may cost time and resources later on.

2026 How to Select the Right Cryogenic Check Valve for Your Applications? - Understanding the Basics of Cryogenic Check Valves

| Dimension | Description | Material | Temperature Range (°C) | Pressure Rating (PSI) |

|---|---|---|---|---|

| 1" | Standard cryogenic application | Stainless Steel | -196 to 50 | 3000 |

| 2" | High flow capacity | Brass | -196 to 65 | 1500 |

| 3" | Specialized for LNG applications | Carbon Steel | -162 to 50 | 2500 |

| 4" | Versatile use for various cryogenic fluids | Monel | -253 to 60 | 2000 |

Identifying Different Types of Cryogenic Check Valves

When selecting cryogenic check valves, it's essential to understand the various types available. There are typically two main categories: spring-loaded and weight-loaded valves.

Spring-loaded valves use a spring mechanism to close the valve. They are effective for maintaining a tight seal at low temperatures. These valves operate quickly and react promptly to pressure changes.

On the other hand, weight-loaded valves rely on gravity to function. They usually have a heavier closure element that falls back into place to stop flow. This type is simpler in design and may be more durable. However, it can be slower in reaction time compared to spring-loaded versions. Choosing the right type depends on your specific applications and operational conditions.

Each type has its pros and cons. The wrong choice can lead to inefficiency. Reflecting on your application needs is crucial. Consider factors like pressure fluctuations, flow rates, and the working environment. It's a challenging task to find the perfect match. Often, compromises must be made. Hence, careful evaluation is key to effective decision-making.

Evaluating Material Compatibility for Cryogenic Applications

Selecting the right cryogenic check valve requires careful consideration of material compatibility. In cryogenic applications, temperatures drop significantly, often below -150°C. This extreme environment can affect materials in unpredictable ways. Metals can become brittle, while seals and gaskets may fail.

Ignoring these factors can lead to valve failure and safety hazards. It’s essential to evaluate the materials used in check valves. Stainless steel, for instance, is a popular choice but can be susceptible to stress corrosion. Other options like aluminum may perform better at low temperatures but have limitations in pressure ratings. Each material's performance varies with different cryogenic fluids, which adds complexity.

Testing the compatibility of materials is vital. Conducting trials in controlled environments simulates actual conditions. It's also beneficial to consult with manufacturers who specialize in cryogenic applications. Ensure they understand your specific needs. This process may be time-consuming but is critical for long-term reliability. Balancing performance with safety should be the ultimate goal in selecting the right components.

Material Compatibility Evaluation for Cryogenic Check Valves

This chart illustrates the compatibility ratings of various materials commonly used in cryogenic applications. Materials are evaluated based on their performance in low-temperature environments, allowing engineers to select the most suitable check valve material for their specific applications.

Assessing Pressure and Temperature Ratings for Valves

When selecting cryogenic check valves, pressure and temperature ratings play crucial roles. These valves often operate in extreme conditions. For instance, temperatures can drop to -196°C in liquid nitrogen applications. Manufacturers must ensure that the materials used withstand such conditions. Reports indicate that failure to match valve ratings can lead to leaks or catastrophic failures.

Pressure ratings are equally important. Most cryogenic valves handle pressures exceeding 10,000 psi. Valves must be tested rigorously to maintain safety and reliability. The American Society of Mechanical Engineers (ASME) provides guidelines, but not every manufacturer adheres to them. Sometimes, manufacturers overestimate their products' capabilities. This can lead to dangerous situations in critical applications.

Choosing the right valve is a complex task. It requires understanding specific operational environments. Incompatible materials can cause embrittlement at low temperatures. This factor should not be overlooked. Ongoing discussions in the industry often highlight these challenges. A lack of proper testing can mean risking safety and efficiency.

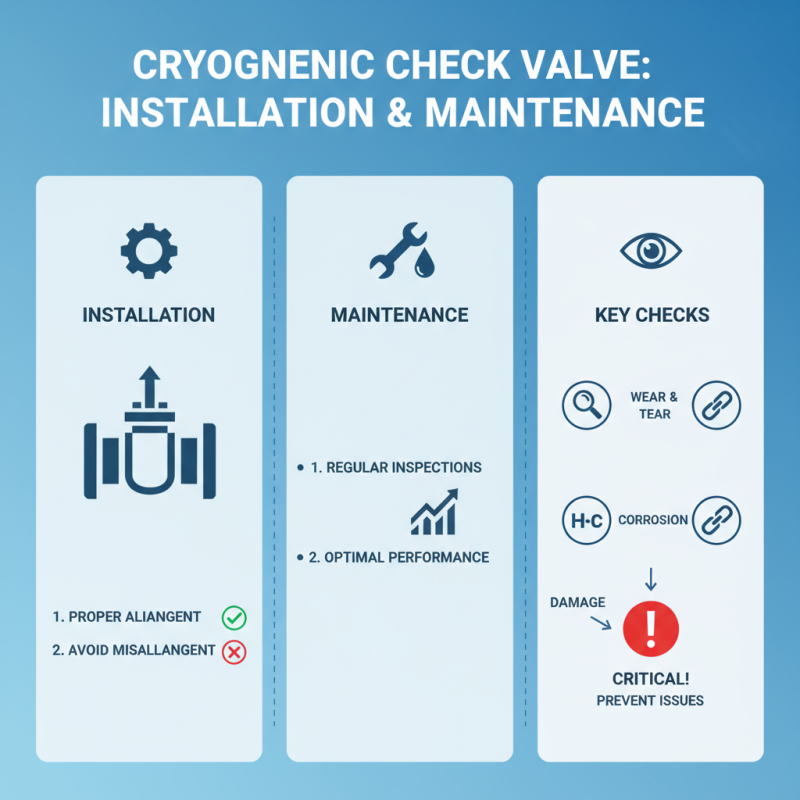

Determining Installation and Maintenance Requirements for Optimal Performance

When selecting a cryogenic check valve, understanding installation and maintenance requirements is vital. The right maintenance ensures optimal performance. Regular inspections help identify wear and tear. Look for signs of corrosion or damage. Misalignment during installation can lead to severe issues.

Tips: Always verify that the valves are properly sealed. This prevents leaks that can escalate problems later. Consider the surroundings of the valve too. Extreme temperatures and pressures can affect its lifespan.

You may need a trained technician for installation. A correct setup minimizes risks. However, sometimes, even experienced staff can make mistakes. Double-check the alignment and the torque settings. It may seem minor, but these details are critical in cryogenic applications.

It's wise to develop a routine for periodic maintenance. This is often overlooked. A lack of routine leads to unexpected failures. Schedule inspections based on usage rates. Monitoring your valve's condition can save significant costs over time.

Related Posts

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

Best Cryogenic Check Valves for Essential Applications in Cold Environments

-

Why a Safety Valve is Essential for Industrial Equipment in 2026

-

How to Choose the Right Safety Valve for Your Application?

-

10 Best Control Valves for Optimal Process Management?

-

How to Choose the Right Control Valve for Your Industrial Applications