2025's Top 5 Ball Valve Innovations for Efficient Fluid Control Systems

As industries continue to evolve, the importance of efficient fluid control systems cannot be overstated. In this context, ball valves have emerged as crucial components, designed to regulate fluid flow with precision and reliability. According to industry expert Dr. Emily Carter, a leading authority on valve technologies, "The advancements in ball valve design and functionality are paving the way for more sustainable and efficient fluid management solutions." This statement underscores the urgency and significance of innovating within the ball valve sector, especially as we approach 2025.

As industries continue to evolve, the importance of efficient fluid control systems cannot be overstated. In this context, ball valves have emerged as crucial components, designed to regulate fluid flow with precision and reliability. According to industry expert Dr. Emily Carter, a leading authority on valve technologies, "The advancements in ball valve design and functionality are paving the way for more sustainable and efficient fluid management solutions." This statement underscores the urgency and significance of innovating within the ball valve sector, especially as we approach 2025.

As we look forward, several innovations are set to reshape the landscape of ball valves, enhancing their performance and adaptability in various applications. These improvements not only promise to elevate operational efficiency but also address the growing demand for sustainable practices in fluid control systems. The upcoming technologies will play a crucial role in ensuring that ball valves meet the challenges posed by evolving industry standards and environmental regulations.

In this article, we will explore the top five innovations in ball valve technology anticipated for 2025, delving into their potential impact on industries reliant on fluid control. By examining these advancements, we aim to provide insights into how these innovations will contribute to operational excellence while promoting sustainability in an increasingly conscientious market.

Top 5 Game-Changing Ball Valve Technologies Transforming Fluid Control in 2025

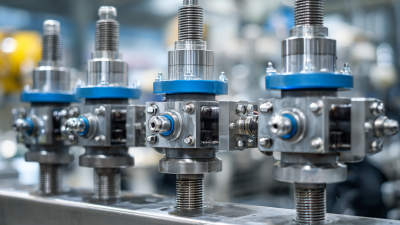

In 2025, the landscape of fluid control systems is set to be revolutionized by groundbreaking ball valve technologies. One of the most significant innovations is the integration of IoT-enabled ball valves, which enhance real-time monitoring and control capabilities. According to a recent industry report by MarketsandMarkets, the global smart valve market is anticipated to reach USD 4.5 billion by 2025, growing at a CAGR of 11.5%. This surge indicates a rising demand for precision and efficiency in various applications, from oil and gas to water treatment.

Additionally, advanced materials such as thermoplastic and composite structures are being employed to produce lighter and more durable ball valves. These materials not only improve the lifespan of the valves but also reduce energy consumption across systems. A study published in the Journal of Fluid Engineering highlights that utilizing such materials can lead to a 15% decrease in operational costs due to reduced friction and lower wear in high-pressure environments. As these game-changing technologies emerge, they promise to transform fluid control systems, elevating operational efficiency and reliability in various industrial sectors.

Impact of Smart Valve Solutions on Operational Efficiency and Cost Reduction

The pharmaceutical industry is experiencing significant growth, particularly in the diaphragm valve market, which is estimated to reach USD 123.3 million in 2024 and surge to USD 284.6 million by 2032, exhibiting a compound annual growth rate (CAGR) of 11.02%. This upward trend is driven by the increasing demand for efficient and precise fluid control systems that smart valve solutions can provide. As operational efficiency remains at the forefront of industry goals, intelligent valve systems leverage real-time data to optimize flow rates and reduce waste, thus contributing to substantial cost savings.

In parallel, the transition towards digitalization in the refining and petrochemical sectors is fostering innovation. The integration of smart technologies into valve solutions enhances the operational lifespan and reliability of systems, ensuring that plants operate seamlessly and efficiently. With the projected growth of the acid gas valve market from USD 98.3 million in 2024 to USD 147.09 million by 2032, reflecting a growth rate of 5.1%, it is evident that stakeholders are increasingly investing in technologies that not only streamline processes but also significantly cut operational costs amidst evolving market demands.

2025's Top 5 Ball Valve Innovations for Efficient Fluid Control Systems

| Innovation | Features | Impact on Efficiency | Cost Reduction (%) |

|---|---|---|---|

| Smart Actuation Technology | Remote operation and automation capabilities. | Increases operational speed and reduces manual intervention. | 30% |

| Real-Time Monitoring Sensors | Continuous data collection for flow and pressure. | Enhances predictive maintenance and reduces downtime. | 25% |

| Advanced Materials | Enhanced corrosion resistance and durability. | Lowers replacement frequency and maintenance costs. | 15% |

| AI-driven Analytics | Data analysis for optimal valve performance. | Maximizes efficiency and reduces waste. | 20% |

| Energy Harvesting Technology | Utilizes flow energy to power devices. | Reduces energy consumption for control systems. | 10% |

Emergence of Sustainable Materials in Ball Valve Manufacturing for Eco-friendly Systems

The emergence of sustainable materials in ball valve manufacturing is transforming fluid control systems, making them more eco-friendly and efficient. According to a recent report by the International Energy Agency (IEA), the global demand for sustainable materials in industrial applications is projected to grow by 25% by 2025, reflecting an intensified focus on environmental responsibility. Ball valve manufacturers are increasingly adopting environmentally friendly materials such as bio-based polymers and recycled metals, which not only reduce the carbon footprint but also enhance the durability and performance of the valves.

Moreover, advancements in material science have led to the development of innovative coatings that minimize wear and corrosion, further extending the lifespan of ball valves in various applications. A study published by the Materials Research Society indicates that valves made from sustainable materials can reduce lifecycle emissions by up to 30%. This shift not only meets the demands of regulatory standards but also aligns with corporate sustainability goals, ensuring that fluid control systems contribute positively to the environment. As industries prioritize eco-friendly solutions, the integration of sustainable materials in ball valve manufacturing is set to play a crucial role in driving efficiency and reducing environmental impact.

2025's Top 5 Ball Valve Innovations for Efficient Fluid Control Systems

This chart illustrates the advancements in ball valve technology for 2025, emphasizing the types of sustainable materials being utilized in their manufacturing. The data reflects both the percentage of adoption and efficiency improvements associated with each innovation.

The Role of AI and IoT in Enhancing Ball Valve Performance Monitoring and Maintenance

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) significantly enhances the performance monitoring and maintenance of ball valves in fluid control systems. With smart sensors embedded within these valves, real-time data regarding flow rates, pressure levels, and valve integrity can be continuously monitored. This data is transmitted to cloud-based platforms, allowing for sophisticated analytics and immediate alerting systems to identify potential issues before they escalate into significant failures.

Tips: Regularly updating software and ensuring all devices are synced with the latest security protocols can greatly enhance the safety and efficiency of your ball valve operations. Additionally, consider investing in predictive maintenance tools that utilize AI algorithms—these can forecast when a valve might fail, allowing for preemptive repairs that minimize downtime.

Moreover, the use of IoT devices enables seamless communication between various components of the fluid control system. This interconnectedness allows for a comprehensive view of the system's health, improving overall management. By analyzing historical data and performance patterns, operators can make informed decisions about maintenance schedules, leading to enhanced reliability and prolonged lifespan of ball valves.

Tips: Establish a routine for reviewing the data analytics provided by these smart systems. This practice can help identify trends that may indicate upcoming maintenance needs, allowing for timely interventions and reducing potential operational disruptions.

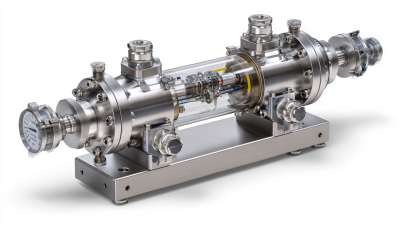

Advancements in Sealing Technologies: Improving Reliability and Longevity of Ball Valves

The ball valve industry is undergoing significant transformations, particularly in sealing technologies, which are critical for enhancing the reliability and longevity of fluid control systems. According to a recent report by MarketsandMarkets, the global ball valve market is expected to grow from USD 14.0 billion in 2020 to USD 20.0 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.2%. This growth can be largely attributed to the advancements in sealing materials and designs that are being developed to withstand harsh operating conditions, including extreme temperatures and pressures.

Recent innovations such as multi-layered seat designs, advanced elastomer technologies, and improved anti-blowout features are revolutionizing the performance of ball valves. For instance, the use of high-performance thermoplastics and synthetic elastomers can significantly enhance sealing performance, reducing leakage rates to below 0.01% of the valve's rated flow capacity, as confirmed by the American Petroleum Institute (API) standards. These advancements not only optimize fluid control but also minimize maintenance needs, thereby extending the lifespan of ball valves in critical applications across various industries, including oil and gas, water treatment, and process control.

Related Posts

-

Understanding the Key Benefits of Using Ball Valves in Modern Plumbing Systems

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

Why Choosing the Right Pressure Relief Valve is Essential for Safety and Efficiency

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications