Top 10 Check Valve Types for Optimal Flow Control and Industry Applications

Check valves are essential components in various industrial applications, playing a crucial role in ensuring optimal flow control by allowing fluid to pass in one direction while preventing backflow. As per the latest market research report from Grand View Research, the global check valve market size was valued at approximately USD 2.3 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2021 to 2028. This growth is a testament to the increasing demand for efficient fluid management and safety regulations across industries such as oil and gas, water and wastewater treatment, and chemical processing.

The effectiveness of check valves in maintaining system integrity can greatly influence operational efficiency and safety. For instance, a malfunctioning check valve can lead to significant downtime and costly repairs—a risk that industries are keen to mitigate. According to a report by Technavio, the increasing investment in infrastructure projects worldwide is further driving the demand for various check valve types, highlighting the necessity for industry professionals to be familiar with the top check valve types available. In this article, we will explore the top 10 check valve types, their optimal applications, and valuable tips for ensuring maximum performance and reliability in flow control systems.

Top 5 Check Valve Types for Enhanced Fluid Control in Industrial Systems

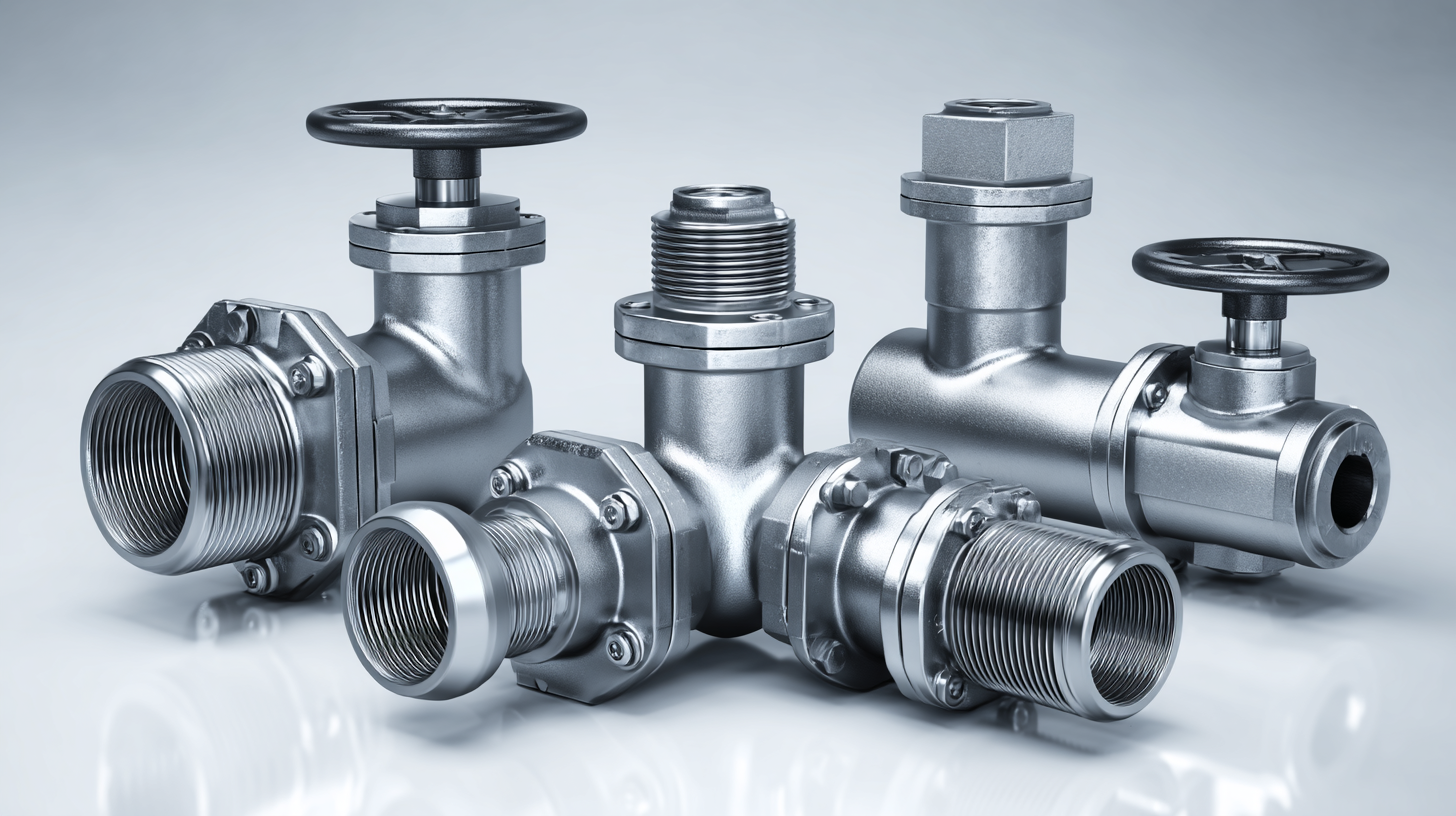

Check valves are essential components in industrial systems, ensuring that fluid flows in the desired direction while preventing backflow. One of the top types of check valves is the **Swing Check Valve**, known for its simple design and effectiveness in high-flow applications. Its disc swings on a hinge, allowing fluid to flow through and preventing reverse flow, making it suitable for water, oils, and gases in various industries.

Another notable type is the **Lift Check Valve**, which operates similarly to a swing check valve but with a vertical lift mechanism. This design is especially beneficial for applications requiring tight sealing and minimal pressure drop, commonly found in steam and condensate systems. Lastly, the **Dual Plate Check Valve** offers a compact flow path and lightweight design, making it ideal for space-constrained environments while maintaining reliability in backflow prevention. These check valves play a pivotal role in optimizing fluid control and extending the lifespan of industrial systems.

Top 10 Check Valve Types for Optimal Flow Control and Industry Applications

| Check Valve Type | Description | Applications | Material |

|---|---|---|---|

| Ball Check Valve | Utilizes a sphere to prevent backflow. | Pipelines, water supply systems. | Brass, Stainless Steel. |

| Swing Check Valve | Uses a hinged disc to allow flow in one direction. | Water, oil, gas systems. | Cast Iron, PVC. |

| Lift Check Valve | Uses a disc that lifts to allow flow. | High-pressure applications. | Stainless Steel, Bronze. |

| Dual Plate Check Valve | Two plates open and close quickly. | Pipelines, HVAC systems. | Carbon Steel, Alloy Steel. |

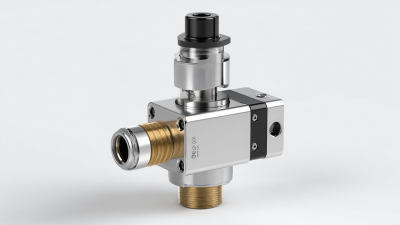

| Spring Check Valve | Employs a spring mechanism to prevent backflow. | Hydraulic systems. | Stainless Steel, Plastic. |

| Tilting Disc Check Valve | Disc tilts to open, features low pressure loss. | Chemical processing. | Cast Steel, Stainless Steel. |

| Piston Check Valve | A piston moves to allow or block flow. | Oil and gas pipelines. | Aluminum, Brass. |

| Non-Return Valve | Prevent backflow in a piping system. | Water treatment. | Plastic, Cast Iron. |

| Ductile Iron Check Valve | Durable for tough environments. | Sewage and wastewater. | Ductile Iron. |

Key Specifications and Performance Metrics for Top Check Valve Types

Check valves are essential components in fluid systems, ensuring flow in a single direction and preventing backflow. When selecting a check valve, understanding key specifications and performance metrics is crucial. Factors such as pressure rating, temperature range, and materials of construction determine how well a check valve will perform in specific applications. For example, stainless steel valves offer excellent corrosion resistance for chemical processing, while plastic valves may be more suitable for less demanding environments.

Check valves are essential components in fluid systems, ensuring flow in a single direction and preventing backflow. When selecting a check valve, understanding key specifications and performance metrics is crucial. Factors such as pressure rating, temperature range, and materials of construction determine how well a check valve will perform in specific applications. For example, stainless steel valves offer excellent corrosion resistance for chemical processing, while plastic valves may be more suitable for less demanding environments.

Tip: Always consider the system's pressure and temperature conditions to ensure compatibility. Also, assess the potential for solids in the fluid; some check valves are better equipped to handle particulates than others.

Another important specification is the valve size and flow capacity, which directly impacts the effectiveness of flow control. Flow coefficients (Cv values) provide a measure of a valve's capacity to allow fluid flow, helping engineers to design systems that maintain optimal efficiency. Additionally, understanding the closing speed of the valve can prevent water hammer and prolong the valve's lifespan.

Tip: Regularly inspect your check valves to ensure they work as intended, especially in high-demand systems. Maintenance can help identify wear and extend operational reliability.

Comparative Analysis of Swing vs. Lift Check Valves in Flow Applications

In the realm of flow control, understanding the nuances between swing and lift check valves is crucial for optimizing system efficiency across various industries. Swing check valves, known for their simple design and effective backflow prevention, are often preferred in applications where the flow is consistent and can maintain enough pressure to keep the valve disc fully open. On the other hand, lift check valves, which can operate effectively even in low-pressure environments, are especially beneficial in dynamic applications where flow rates fluctuate. According to a report by the Flow Control Association, the right choice can lead to performance improvements of over 20% in some fluid systems, emphasizing the importance of selecting the appropriate valve type for specific applications.

Furthermore, recent advancements in plunger lifting optimization control methods highlight the evolving landscape of flow management. Techniques such as the Adaptive Particle Swarm Optimization Model Predictive Control (APSO-MPC) are being employed in edge computing applications to enhance gas extraction processes, particularly in shale gas operations. Efficient plunger lift systems can significantly mitigate bottomhole liquid loading effects, improving the overall gas well productivity by as much as 30%. As industries continue to adapt to new technologies, the comparative analysis of swing vs. lift check valves remains pivotal in ensuring optimal performance and operational success.

Top 10 Check Valve Types for Optimal Flow Control

Impact of Check Valve Selection on Energy Efficiency in Pump Systems

The selection of the right check valve is crucial for enhancing energy efficiency in pump systems. According to a report by the Hydraulic Institute, improper valve selection can lead to energy losses of up to 30%. This inefficiency occurs when valves do not open or close appropriately, causing unnecessary strain on pumps and increasing operational costs. By optimizing valve design and selection, industries can significantly reduce energy consumption and prolong the operational lifespan of pumps.

Tip: Always choose check valves that are specifically designed for the fluid characteristics and operating conditions of your system. This can help minimize turbulence and pressure drops, contributing to greater energy savings.

In addition to energy efficiency, selected check valves also impact flow control and maintenance requirements. As noted in the American Society of Mechanical Engineers (ASME) review, utilizing valves that are tailored to specific industrial applications can lead to a reduction in maintenance frequency by up to 25%. This not only saves on maintenance costs but also ensures smooth and efficient operations in critical processes.

Tip: Regularly assess and optimize your check valve inventory to align with current operational needs and technological advancements. This proactive approach can lead to sustained energy efficiency and operational excellence in the long run.

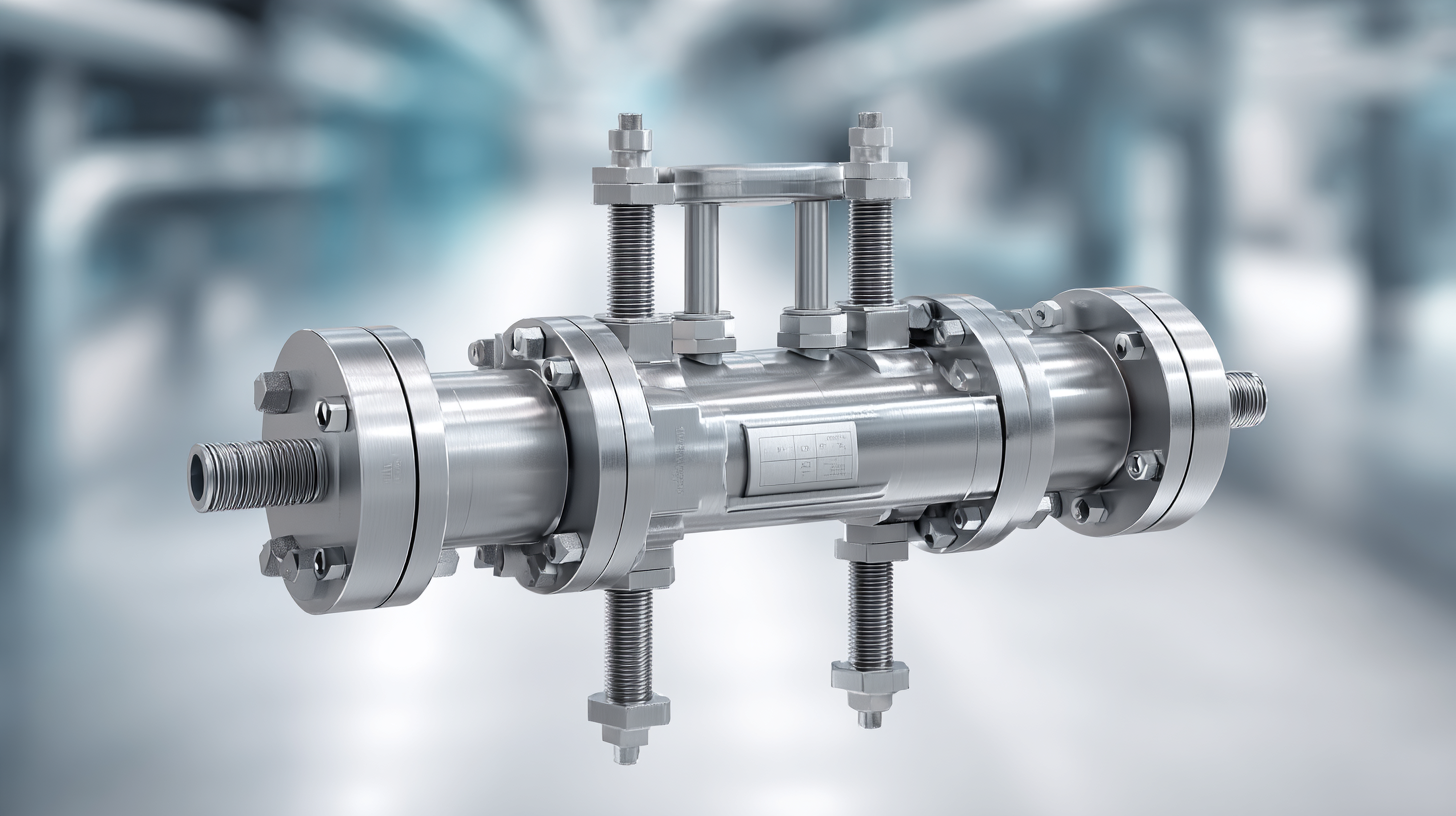

Industry-Specific Applications: Check Valves in Oil, Gas, and Water Treatment

Check valves play a crucial role in various industrial applications, particularly in sectors like oil, gas, and water treatment. These components ensure optimal flow control by allowing fluid to flow in one direction only, preventing backflow and potential system failures. According to market analyses, the global motor starters market is projected to reach USD 12.8 billion by 2034, growing at a CAGR of 5.8%. This growth is reflective of the rising demand for reliable flow control mechanisms, driving the need for efficient check valves across multiple industries.

In the oil and gas sector, check valves are essential for managing flow and maintaining pressure in pipelines. With the industrial valves market expected to expand significantly, reaching noteworthy milestones by 2033, the demand for various valve types, including check valves, is anticipated to rise correspondingly. The usage of these valves in water treatment processes highlights their importance in ensuring environmental safety and compliance with regulatory standards. As industries evolve and expand, the strategic implementation of check valves will continue to be a focal point for enhancing operational efficiency and system reliability.

Related Posts

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

-

Understanding the Importance of Control Valves in Modern Industrial Applications

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair