2026 Top Electronic Valve Innovations and Trends to Watch?

The electronic valve industry is undergoing remarkable advancements. As we look toward 2026, the trends shape the future of fluid control and automation. Experts predict that innovations will enhance efficiency and sustainability in various sectors.

Dr. Henry Liu, a leading figure in the electronic valve field, states, “The future of electronic valves will redefine how industries operate.” His insights highlight the potential for smart systems that adapt in real-time.

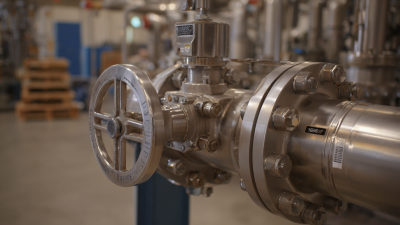

Many electronic valves are becoming more intricate and compact. They promise to save space and energy. However, challenges remain in balancing cost and functionality. As the technology evolves, manufacturers must address these concerns. In this fast-paced environment, understanding upcoming trends is crucial for success.

Emerging Technologies in Electronic Valve Design for 2026

As the electronic valve industry evolves, new technologies are reshaping designs for 2026. Advanced materials are at the forefront. Reports indicate that the use of lightweight alloys and smart polymers can significantly enhance performance. These materials can reduce wear and extend lifecycle, yet they also raise concerns about reliability under extreme conditions.

AI and machine learning applications are gaining traction in valve design. Predictive analytics can optimize operation, potentially decreasing maintenance costs by up to 20%. However, reliance on these technologies brings questions about cybersecurity. Protecting critical infrastructure from cyber threats is vital. This duality of innovation and risk is something the industry must confront.

Additionally, sustainability is becoming an urgent focus. Innovative valves designed for water-saving applications are now available. Research shows that these can contribute to reductions in water use by up to 40% in industrial settings. Yet, the initial cash outlay for such technologies can deter some businesses. Balancing upfront costs and long-term savings will be key for widespread adoption.

2026 Top Electronic Valve Innovations and Trends to Watch

This chart illustrates the predicted impact scores for key electronic valve innovations and trends in 2026. The scores indicate the expected significance of each trend, with a higher score representing a greater impact on the industry.

Key Innovations in Material Science Impacting Electronic Valves

Recent advancements in material science are reshaping the landscape of electronic valves. Innovative materials enhance durability and performance. For instance, high-temperature polymers are becoming prevalent. They offer excellent resistance to thermal degradation. This change improves the reliability of electronic valves in extreme conditions.

Another trend involves the use of nanomaterials. These substances can significantly reduce the weight of traditional components. Lighter valves can improve energy efficiency. They can also lead to smarter designs. Initial trials show promising results, yet more testing is needed. Surprises often arise during practical applications, leading to unexpected challenges.

Additionally, eco-friendly materials are gaining attention. The push for sustainability affects design choices in electronic valves. Companies are exploring biodegradable options. However, performance evaluation remains critical. How these materials hold up under pressure is still uncertain. Balancing environmental concerns with performance is an ongoing debate. The future holds exciting, yet challenging opportunities in this dynamic field.

2026 Top Electronic Valve Innovations and Trends to Watch

| Innovation | Key Features | Impact on Industry | Emerging Materials | Application Areas |

|---|---|---|---|---|

| Smart Electro-Mechanical Valves | Integration with IoT, remote control | Increased efficiency and precision in control systems | Composite materials with enhanced durability | Oil and gas, water management |

| Nano-Coated Valves | Self-cleaning surfaces, corrosion resistance | Reduced maintenance costs and increased lifespan | Graphene and carbon nanotubes | Chemical processing, pharmaceuticals |

| Flexible Electronic Valves | Bendable designs for unique applications | Expanded use in compact and portable devices | Flexible polymers and advanced composites | Wearable tech, portable medical devices |

| Ultra-Fast Responsive Valves | Quick action, reducing lag time | Enhanced performance in high-speed applications | High-speed actuating materials | Automotive, aerospace |

| AI-Driven Control Systems | Self-optimizing control algorithms | Significantly improved operational efficiency | Smart materials and AI technologies | Manufacturing, logistics |

Smart Valves: Integration of IoT and Automation in 2026

The integration of IoT and automation in smart valves is set to revolutionize the industry by 2026. Smart valves enable real-time monitoring and control. They can optimize processes that were once manual and time-consuming. Imagine a system that adjusts the flow based on demand automatically. This innovation saves energy and reduces waste.

The data collected by smart valves can be analyzed for predictive maintenance. This helps prevent unexpected failures. However, there are challenges to consider. Cybersecurity is a significant concern as devices become more interconnected. Ensuring data integrity and safety is vital. Companies must remain vigilant against potential threats.

Tip: Start small. Implement smart valves in one area of your operation. Monitor their performance before scaling up. Evaluate the results and refine the approach. This allows you to learn and adapt.

Embracing these innovations requires a mindset shift. Teams may need training to manage new technologies effectively. There might be resistance to change. Open communication is essential to address concerns and foster acceptance. Explore how these smart solutions can align with your organizational goals.

Advancements in Energy Efficiency and Sustainability for Valves

The landscape of electronic valves is rapidly changing. Emphasis on energy efficiency is leading to innovative designs. Many engineers are focusing on reducing energy waste. Smart sensors are emerging, allowing real-time monitoring of valve performance. These advancements can significantly minimize energy consumption.

Sustainability is a crucial theme in this sector. New materials are being developed that are both durable and eco-friendly. Some valves now incorporate recyclable components, providing a second life after their use. These trends may not eliminate all issues, though. Challenges remain in balancing performance and environmental impact.

While strides are being made, achieving perfect efficiency remains a goal. The path to sustainability is not easy. Some existing technologies may not be up to par. Therefore, continuous research and iteration are needed to drive improvements forward. The industry is on the brink of transformation but still requires reflection and adjustment.

Market Trends and Consumer Demands Shaping Valve Innovations

The electronic valve market is rapidly evolving. Recent studies indicate a shift towards smart valve technologies driven by consumer demand for efficiency. Research by MarketsandMarkets predicts that the smart valve market will grow from $2.4 billion in 2021 to $3.8 billion by 2026. This change is fueled by industries seeking automation and improved operational control.

At the same time, consumers are increasingly concerned about sustainability. Many industries are prioritizing environmentally friendly solutions. Data from the International Energy Agency shows that efficient valves can reduce energy consumption by up to 30%. However, not all innovations meet these standards. Some electronic valves remain less efficient, raising questions about their true impact.

Moreover, the integration of IoT (Internet of Things) technology is reshaping consumer expectations. Valves equipped with IoT capabilities enable real-time monitoring and predictive maintenance. A report by Gartner highlights that 50% of organizations will invest in IoT-enabled devices by 2025. Yet, inconsistencies in data management continue to be an obstacle. The path to full integration is still under scrutiny, revealing both potential and limitations in current offerings.

Related Posts

-

How to Choose the Right Cryogenic Valves for Your Applications

-

Top 10 Benefits of Using Flow Check Valves in Your Plumbing System

-

Top 10 Check Valve Types for Optimal Flow Control and Industry Applications

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

2025's Top 5 Ball Valve Innovations for Efficient Fluid Control Systems

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs