2026 Top Electronic Valve Innovations Changing the Industry?

The future of the electronic valve industry is bright. Innovations in technology are reshaping how we use these crucial components. Electronic valves are becoming smarter and more efficient. They help control fluid flow in various applications. This trend is not just about convenience; it is about enhancing performance.

As we look forward to 2026, several key innovations are emerging. These advancements could improve reliability and reduce energy consumption. Higher precision and better response times are on the horizon. However, these changes also bring challenges. Not all innovations are perfect. Some may complicate existing systems or lead to unforeseen issues.

The evolution of electronic valves is necessary for industrial growth. Exploring these innovations will reveal their impacts. Will they be beneficial for all sectors? Only time will tell. The journey of electronic valve technology is one not to overlook.

2026 Trends in Electronic Valve Innovations Impacting Industrial Applications

The landscape of electronic valves is evolving rapidly. In 2026, we can expect significant innovations that will impact various industrial applications. According to a recent industry report, the electronic valve market is projected to grow at a CAGR of 8% over the next five years. This growth is driven by advancements in automation and control systems.

New materials and designs are improving efficiency. For instance, smart valves are now equipped with AI capabilities. These valves can analyze data in real-time, allowing for better decision-making in industrial processes. Yet, the implementation of such technologies comes with challenges. Employees must adapt to these new systems, which requires training and a shift in mindset.

Tip: Ensure your team is prepared for these changes. Training sessions on new technologies can boost confidence and competence.

Furthermore, sustainability is a pressing concern. As regulations become stricter, industries need to reduce emissions. Innovative electronic valves can contribute to this effort by optimizing fluid control processes. However, companies may face hurdles when integrating these solutions into existing frameworks.

Tip: Conduct regular assessments of your systems. This helps identify areas for improvement and integration challenges.

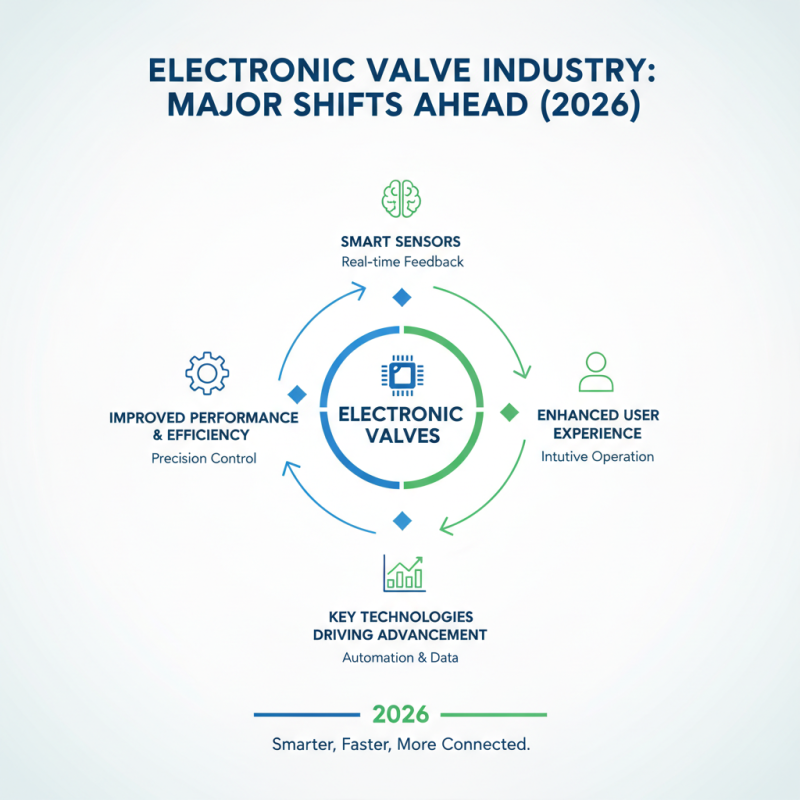

Key Technologies Driving Electronic Valve Advancements in 2026

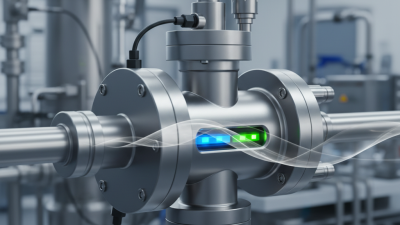

The electronic valve industry is on the cusp of significant change. In 2026, several key technologies are driving advancements in electronic valves. These innovations focus on improving performance, efficiency, and user experience. Smart sensors are becoming ubiquitous. They provide real-time feedback. This leads to better control and precision in various applications.

The integration of artificial intelligence (AI) plays a vital role. AI algorithms analyze data, predicting valve behavior under different conditions. This adaptive response enhances reliability. Companies are experimenting, yet challenges remain. Some systems struggle to communicate seamlessly, leading to inefficiencies. Connectivity issues can arise, making troubleshooting difficult.

Moreover, the move towards sustainable solutions is prominent. Energy-efficient designs reduce resource consumption. However, transitioning can be slow. Manufacturers grapple with balancing cost and innovation. Not every attempt to innovatively address these issues has succeeded. The journey toward improving electronic valves is filled with both breakthroughs and setbacks.

Challenges and Solutions in Developing Next-Generation Electronic Valves

The development of next-generation electronic valves faces significant challenges. Engineers must balance performance with cost. Innovations often demand high precision and reliability, making materials a crucial consideration. For instance, lightweight but durable materials can enhance performance, but they may be expensive or hard to source.

Design complexity is another hurdle. Many designs are intricate and require advanced manufacturing techniques. Simpler designs can reduce costs but may compromise functionality. Finding that balance is essential. Engineers often engage in trials and errors to refine their designs. This iterative process can delay product launches and increase costs.

**Tips:**

1. Always prototype early. Early testing reveals design flaws before large-scale production.

2. Embrace feedback from users. It can provide insights that engineers often overlook.

3. Don’t rush. Quality is paramount in the development of electronic valves.

2026 Top Electronic Valve Innovations Changing the Industry

This chart illustrates the key innovations and challenges in the electronic valve industry for 2026. The data represents various technological advancements and their anticipated market impact.

The Role of Automation in Evolving Electronic Valve Technologies

The integration of automation in electronic valve technologies is transforming the industry significantly. Automation helps in optimizing control processes, reducing manual errors, and increasing efficiency. A recent industry report revealed that automation in valve systems could enhance performance by up to 30%. This improvement is crucial as industries look to increase their output while minimizing waste.

Automation contributes to better monitoring and data collection. Real-time data helps in predictive maintenance. This approach prevents unexpected downtimes, saving costs and resources. It enables industries to respond quickly to changes in demand. Engineers must adapt to new systems that incorporate advanced algorithms and smart tools.

Tip: Investing in training programs for your team is essential. Automation tools can be complex, and understanding their functionalities is key.

The rise of digital twins is a critical trend. It enables simulations that can predict how valves respond under different conditions. This technology enhances designs, ensuring reliability. Companies that embrace these innovations will likely see a competitive edge.

Tip: Always review your current systems. Small adjustments can lead to substantial efficiency gains. Evaluate your operational workflows regularly and remain open to new ideas.

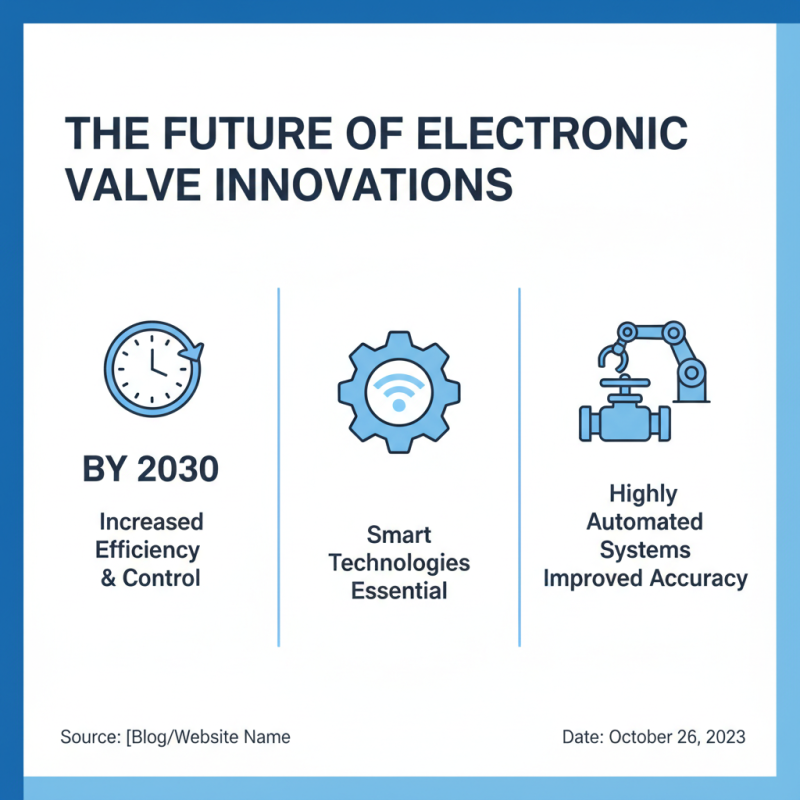

Future Outlook: Predictions for Electronic Valve Innovations by 2030

The future of electronic valve innovations looks promising. By 2030, we can expect significant advancements in efficiency and control. Smart technologies are becoming essential. These innovations may lead to highly automated systems that improve accuracy in various applications.

Using artificial intelligence, electronic valves will become smarter. They will adapt to real-time data and environmental conditions. This feature could enhance system stability and energy efficiency. However, challenges will still remain. Integration with existing systems may prove difficult for engineers.

**Tip:** Explore interoperability early on. Effective communication between devices is crucial.

Innovations will also focus on sustainability. New materials could reduce waste and energy consumption. Yet, how these materials perform under stress is a question to ponder. Testing will be vital to ensure reliability.

**Tip:** Prioritize robust testing phases. It can save time and costs in the long run.

As we approach 2030, the landscape will evolve. Companies must adapt to these changes. Embracing new technology is essential but may require a shift in mindset. The road ahead is promising yet complex.

Related Posts

-

What is an Electronic Valve and How Does it Work in Modern Systems

-

How to Choose the Right Electronic Valve for Your System?

-

2026 Top Electronic Valve Innovations and Trends to Watch?

-

How to Choose the Right Electronic Valve for Your Application?

-

Top 10 Hydrogen Valves for Optimal Performance and Safety in Applications

-

Understanding the Importance of Control Valves in Modern Industrial Applications