2026 Top Flow Check Valve Innovations and Their Applications?

In recent years, flow check valves have gained significant attention. These essential components play a vital role in various industries, ensuring fluid can only flow in one direction. This innovation prevents backflow, protecting systems from potential damage.

The 2026 advancements in flow check valve design show promising improvements. With new materials and technologies, these valves are becoming more reliable and efficient. Enhanced designs are being developed to tackle challenges like pressure fluctuations and wear and tear.

However, not all innovations are perfect. Some designs still struggle with compatibility and maintenance issues. Understanding the strengths and weaknesses of these flow check valves is crucial. As industries evolve, so must the solutions they rely on. This ongoing journey highlights the importance of continuous improvement.

Recent Advances in Flow Check Valve Technology

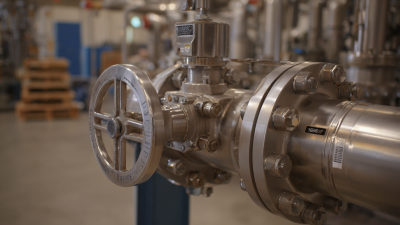

The world of flow check valve technology has seen significant advancements in recent years. According to a recent industry report, the global check valve market is expected to grow by 6.5% annually from 2020 to 2026. This rapid growth highlights the need for improved

reliability and efficiency in various applications, such as water treatment, oil and gas, and chemical processing.

Recent innovations focus on materials and design. Advanced polymers and composites are now common, providing greater resistance to corrosion. This is crucial in harsh environments where traditional materials might fail. Additionally, smart technology integration allows for real-time monitoring of valve performance. An estimated 24% of companies have already adopted such smart solutions.

However, challenges remain. Many manufacturers still rely on outdated designs and materials, leading to inefficiencies. The need for standardization in manufacturing practices is pressing. Industry experts recommend investing in research and development to address these shortfalls. As valve technology evolves, the focus should not only be on innovation but also on overcoming existing limitations to ensure broader industry applications.

Key Features of 2026 Flow Check Valve Innovations

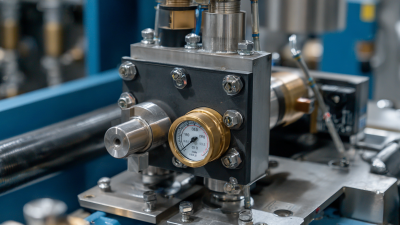

The 2026 flow check valve innovations showcase remarkable advancements in technology and materials. These valves are engineered to enhance efficiency while minimizing pressure loss. Recent surveys suggest that energy savings can exceed 20% in systems utilizing these new designs. Key features include lightweight materials that improve durability. Many valves are now made of advanced polymers and composites, offering better corrosion resistance. This innovation is crucial, particularly in industries where fluid integrity is paramount.

Another significant feature is the integration of smart technology. Sensors embedded within the valves can provide real-time data on pressure and flow rates. This capability allows for predictive maintenance, reducing downtime significantly. Current reports indicate a 30% reduction in maintenance costs for systems using smart check valves. However, challenges persist. Some users report difficulties in the initial setup. The learning curve for smart integrations can be steep, requiring training and adjustments.

In addition to functionality, innovations prioritize safety. New designs often include failsafe mechanisms that prevent backflow, an essential aspect for critical applications. Some industries remain hesitant to adopt these innovations due to perceived risks. Real-world data indicates that despite safety features, improper installation can lead to issues. Continued education on best practices is necessary to fully realize these advancements.

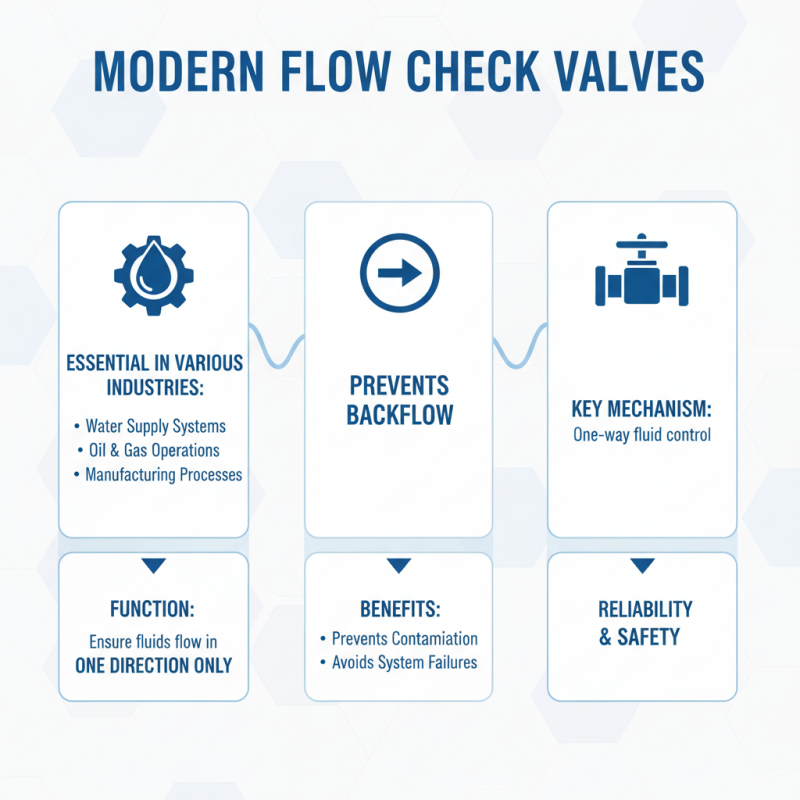

Applications of Modern Flow Check Valves in Various Industries

Modern flow check valves are essential in various industries. They are used in water supply systems, oil and gas operations, and manufacturing processes. These valves ensure that fluids flow in one direction only. This prevents backflow, which can cause contamination or system failures.

In the water industry, these valves are critical for maintaining clean water. They prevent pollutants from entering the supply lines. In the oil and gas sector, they protect equipment from pressure surges. A malfunctioning check valve could lead to leaks or explosions, illustrating the importance of reliability in design.

Moreover, industries like pharmaceuticals also benefit. Here, precise control of liquid flow is crucial. Contaminants can compromise product quality. However, some valves may not respond adequately to varying pressures. This can affect operations. Adapting these valves to handle fluctuations is an ongoing challenge. Improving their designs for different applications remains a focal point for engineers and manufacturers.

Comparative Analysis of Traditional vs. Innovative Flow Check Valves

In recent years, the flow check valve industry has seen significant innovations. Traditional flow check valves often rely on mechanical designs, which can lead to inefficiencies. According to a 2022 industry report, mechanical valves can cause flow restrictions due to wear and tear. These issues can impact system reliability in various applications.

On the other hand, innovative check valves leverage advanced materials and technologies. For example, some new designs feature smart sensors that monitor pressure and flow in real time. A 2023 study found that these valves reduce energy loss by as much as 30%. This capability enables automated adjustments, improving efficiency in water and oil systems.

However, the shift towards these innovations isn't flawless. Many users face challenges in retrofitting existing systems with advanced check valves. Additionally, the cost of cutting-edge designs may deter some industries. In a sector increasingly focused on sustainability, ensuring these solutions are affordable and easy to implement becomes critical.

Future Trends in Flow Check Valve Design and Functionality

The future of flow check valve design is vibrant and evolving. Innovations focus on enhancing energy efficiency and durability. New materials, like advanced polymers, are becoming popular. They offer lighter weight and better corrosion resistance. In a world with fluctuating regulations, these materials provide flexibility for designers.

There’s a strong push towards smart technology integration. Sensors in check valves can monitor flow rates in real time. This data can optimize processes and reduce waste. While this technology offers significant benefits, it also raises concerns about complexity. Users may need training to operate and troubleshoot these systems effectively.

Tip: Always consider the installation environment. Factors like temperature and pressure can affect valve performance. Make sure to evaluate and test prototypes thoroughly. Remember, sometimes the simplest solutions can be the most effective. Keep designs user-friendly to avoid operational challenges down the line.

2026 Flow Check Valve Innovations and Their Applications

This chart illustrates the projected advancements and applications of flow check valve technologies expected in 2026. The data showcases innovative features such as enhanced durability, improved efficiency, and smart integration, highlighting their impact on various industries.

Related Posts

-

Why You Need a Check Valve for Your Plumbing System to Prevent Backflow Issues

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

-

What is a Pressure Control Valve and How Does It Work in Different Applications

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

How to Choose the Right Electronic Valve for Your System?

-

Top 10 Essential Valve Tags for Efficient Industrial Safety Management