2026 Top Pressure Release Valve Features You Should Know?

In industrial settings, the pressure release valve plays a crucial role. These valves help maintain safety by controlling excess pressure in various systems. Knowing the essential features of pressure release valves is vital for effective usage.

Understanding the technology behind pressure release valves can seem complex. Terms like “set pressure” and “blow-off” might confuse some. However, grasping these concepts ensures better decision-making. Valves need to operate efficiently to prevent accidents and failures.

Consider the materials used in a pressure release valve. Corrosion-resistant options are often preferred. They resist wear and tear, increasing the longevity of the valve. Attention to detail is crucial when selecting the right valve for your needs. It’s not just about performance; it’s also about safety and reliability. Remember, a small oversight can lead to significant issues.

Understanding Pressure Release Valves: A Fundamental Overview

Pressure release valves play a critical role in various systems. They help maintain safe operating conditions by alleviating excess pressure. A malfunctioning valve can lead to catastrophic failures or accidents. Understanding how these valves work is essential for safety and efficiency.

When pressure builds up, the valve opens to release the excess. This action prevents system ruptures and explosions. The materials used in the valve's construction are crucial. Metal valves are durable, but plastic valves can be lighter and more economical. Users often overlook the maintenance of these parts, leading to costly repairs or unsafe situations.

Regular inspections are necessary to ensure functionality. Inadequate maintenance can cause a valve to stick or fail. The complexity of the systems they are used in adds to the challenge. Each application may require different specifications and setups. This complexity often leads to confusion or misapplication. Understanding these details is vital for achieving optimal performance and safety.

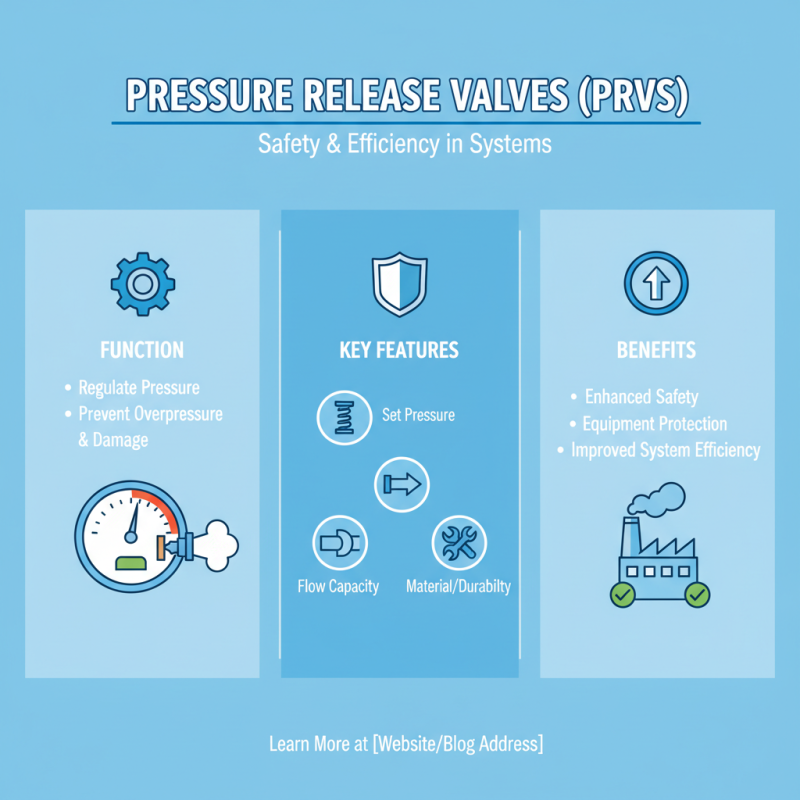

Key Features of Pressure Release Valves Essential for Safety and Efficiency

Pressure release valves (PRVs) are vital components in many systems. They help regulate pressure to prevent dangerous situations. Understanding their key features can enhance safety and efficiency.

One essential feature is the valve's set pressure. This defines the point at which the valve will open. Accurate calibration is crucial. If it’s set too high, pressure may build up dangerously. If it’s too low, the valve could frequently open, leading to inefficiencies.

Another important aspect is the material. Valves made of durable materials resist corrosion and wear. This prolongs their lifespan. However, not all materials are suitable for every application. Choosing the right one requires careful consideration.

Tips: Regular maintenance is key. Check for leaks or wear periodically. Make sure to replace aging valves before they fail. Understanding the specific needs of your system can inform better choices. Don’t overlook manufacturer guidelines, but also trust your experience.

Materials and Design Considerations for Modern Pressure Release Valves

Modern pressure release valves are essential in various industries. The materials used in these valves directly affect their performance. Stainless steel and brass are commonly chosen for their durability and resistance to corrosion. However, some manufacturers might overlook the importance of using high-quality raw materials. This can lead to failures and safety hazards.

Design considerations also play a major role. A well-designed valve should ensure efficiency and safety. Incorrect designs can increase the risk of leaks or malfunctions. It’s important to analyze each component carefully. Even small design flaws can lead to costly issues. Many engineers sometimes rush this stage, assuming everything will work perfectly.

Furthermore, the finish on these valves is critical. A rough finish can trap contaminants, leading to premature failure. Some valves might look good on the surface but hide internal flaws. This aspect of design is often underestimated. Regular testing and evaluation of the manufacturing process are essential. Ensuring compliance with industry standards can make a significant difference.

Common Applications of Pressure Release Valves in Industry and Utilities

Pressure release valves (PRVs) play a vital role in various industries and utilities. They are essential for maintaining safety and efficiency in systems that handle fluids and gases. According to the American Society of Mechanical Engineers (ASME), improper use of PRVs can lead to catastrophic failures, underscoring the necessity for careful design and installation.

In the oil and gas industry, PRVs are used to prevent excessive pressure buildup in pipelines. A report from the International Energy Agency (IEA) highlights that around 10% of offshore accidents are related to pressure control failures. This alarming statistic calls for more rigorous maintenance and monitoring of these devices. In water treatment plants, PRVs help manage pressure in distribution systems, ensuring that water flows properly without causing pipe ruptures. However, inconsistent pressure settings can lead to inefficiencies or system malfunctions.

Utility companies also rely on PRVs for steam and heating systems. The Energy Information Administration (EIA) notes that steam system failures can lead to significant energy waste. Effective pressure control can increase system life and reduce operational costs. Despite their importance, studies indicate that many facilities lack proper training on valve maintenance. This gap emphasizes the need for ongoing education and awareness to harness the full potential of pressure release technology in industrial applications.

2026 Top Pressure Release Valve Features

Future Trends in the Development of Pressure Release Valve Technologies

The future of pressure release valve technologies is evolving rapidly. Innovations in materials and designs are enhancing performance and safety. Lightweight composites and smart sensors are at the forefront. They provide better resilience and adaptability to various pressures. These advancements address ongoing challenges in industries like oil and gas, where reliability is crucial.

New trends also highlight automation in valve management. Smart valves can adjust automatically based on real-time data. This leads to increased efficiency. However, integration into existing systems can be complex. Not all industry players are ready to adopt these changes. Some face resistance due to costs or lack of expertise. The potential for improved safety and reduced downtime remains significant.

Environmental considerations play a vital role in future designs. Sustainable materials are gaining attention. This shift reflects a growing awareness of ecological impacts. Still, not every manufacturer prioritizes sustainability. There's room for improvement in production processes and lifecycle management. A collective industry effort can drive meaningful change. Balancing innovation with practicality is key.

Related Posts

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

What is a Pressure Control Valve and How Does It Work in Different Applications

-

Top 10 Pressure Control Valves: Features, Benefits, and Buying Guide

-

Why a Safety Valve is Essential for Industrial Equipment in 2026

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency