Top 10 Types of Valves: Unlocking Key Insights for Industrial Efficiency

In the ever-evolving landscape of industrial applications, understanding the various types of valves is crucial for optimizing efficiency and ensuring seamless operations. Valves play a pivotal role in controlling the flow of fluids and gases, making them integral to processes across multiple sectors including manufacturing, water treatment, and energy production. As industries strive for enhanced performance and sustainability, the selection of appropriate valve types becomes a fundamental consideration, influencing both the operational reliability and safety of systems.

The upcoming report, "Top 10 Types of Valves: Unlocking Key Insights for Industrial Efficiency," delves into the distinct characteristics and applications of each valve type. From gate valves to ball valves, each variety offers unique functionalities suited to specific operational needs. By outlining the strengths and limitations of these types of valves, the report aims to equip industry professionals with the knowledge necessary to make informed decisions. As we approach 2025, the insights garnered from this analysis will not only highlight the technological advancements in valve design but also address the growing demand for efficiency in industrial processes, ultimately contributing to cost savings and increased productivity.

Understanding the Role of Valves in Industrial Applications

Valves play a crucial role in industrial applications by controlling the flow and pressure of liquids and gases within a system. They are essential components in various sectors, including oil and gas, water treatment, and chemical manufacturing. Understanding the different types of valves and their functions can significantly enhance operational efficiency and safety.

For instance, gate valves are often used for on/off services, while globe valves are favored for throttling.

Tips: When selecting valves for your industrial application, consider the media being transported, as different materials can affect the valve's longevity and performance. Additionally, ensure the valve size aligns with your piping specifications to prevent issues like flow restrictions or turbulence.

The right valve not only optimizes performance but also contributes to minimizing energy consumption and operational costs. Regular maintenance and timely replacements can extend the lifespan of these components, ensuring that processes remain uninterrupted.

Tips: Implement a routine inspection schedule for your valves to detect early signs of wear and tear, which can prevent costly downtime and ensure reliable system performance.

Exploring the Different Types of Valves and Their Unique Functions

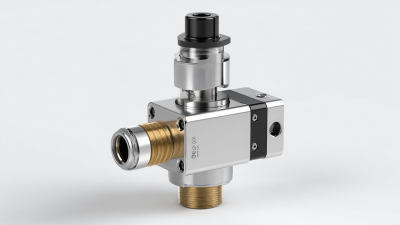

Valves are essential components in various industrial applications, each serving distinct functions that contribute to overall efficiency and safety. The most common types include gate valves, which provide quick on-off control with minimal pressure loss, making them ideal for fully open or closed positions.

Globe valves, on the other hand, are advantageous for regulating flow, thanks to their design that facilitates throttling, thus ensuring precise control over fluid movement.

Another significant type of valve is the check valve, which prevents backflow in pipelines, safeguarding pumps and other equipment from potential damage.

Ball valves, known for their durability and swift operation, are widely used in applications requiring tight sealing and reliable performance. Additionally, butterfly valves are favored in situations that necessitate lightweight solutions and quick actuation, particularly in large volume flow control. Understanding these unique functions allows industries to select the right valve for their specific operational needs, ultimately enhancing efficiency and reliability in their processes.

Key Factors to Consider When Selecting Valves for Efficiency

When selecting valves for industrial applications, various key factors must be considered to ensure optimal efficiency. One critical aspect is flow characteristics. According to a report by the Global Valve Market Research Team, valves that offer linear flow characteristics are preferred for applications requiring precise control, while globe valves are frequently utilized in systems needing throttling capabilities. Understanding the specific flow requirements of the system can significantly impact operational efficiency and energy savings.

Another essential factor is the material compatibility of the valve. A study published in the Journal of Industrial Engineering and Management highlights that approximately 20% of valve failures can be attributed to material degradation. Choosing materials that resist corrosion and wear, such as stainless steel or high-density polyethylene, can extend the life of the valve and reduce maintenance costs. Additionally, considerations related to pressure levels and temperature ranges must align with the material specifications to prevent premature failure and ensure reliable system performance, ultimately contributing to enhanced industrial efficiency.

Innovative Valve Technologies Enhancing Industrial Performance

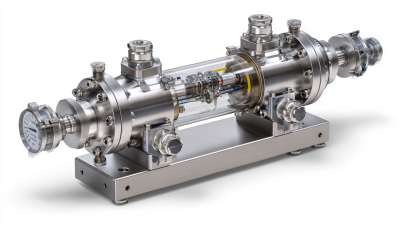

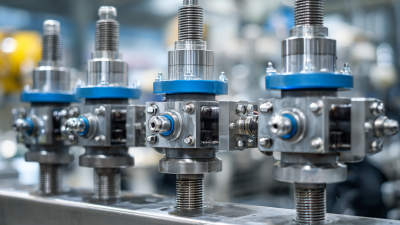

Innovative valve technologies play a crucial role in enhancing industrial performance by optimizing fluid control, improving energy efficiency, and reducing operational costs. Recent advancements in valve design, such as smart valves equipped with sensors and IoT connectivity, allow for real-time monitoring and automated adjustments. These technologies not only ensure precision in flow regulation but also enable predictive maintenance, minimizing downtime and extending equipment longevity.

Moreover, the integration of advanced materials and manufacturing techniques has led to the development of valves with superior durability and resistance to corrosion and wear. For instance, the use of composite materials and advanced coatings can significantly enhance the lifespan of valves operating in harsh environments. By adopting these cutting-edge solutions, industries can achieve higher operational efficiency, leading to increased productivity and sustainability. As the demand for reliable and efficient fluid management systems continues to grow, innovative valve technologies are set to transform industrial processes across various sectors.

Top 10 Types of Valves: Enhancing Industrial Performance

Maintenance Tips for Maximizing Valve Longevity and Efficiency

Maintaining valves is crucial for ensuring their longevity and operational efficiency in industrial applications. Regular inspections can help identify early signs of wear or damage, allowing for timely repairs before more significant issues arise. Operators should establish a routine maintenance schedule that includes checking for leaks, ensuring proper sealing, and monitoring flow rates to detect any irregularities.

Lubrication is another vital aspect of valve maintenance. Different types of valves require specific lubricants, so it’s essential to consult manufacturer guidelines to select the right product. Proper lubrication reduces friction and prevents the accumulation of debris, ultimately extending the valve's lifespan. Additionally, regular cleaning of valve components can prevent blockages and corrosion, further enhancing performance and reliability.

Finally, training personnel on proper handling and operation of valves can significantly impact their longevity. Educating staff on potential operational challenges and effective troubleshooting techniques will ensure that valves are used correctly, minimizing the risk of damage and optimizing functionality throughout their service life. By prioritizing maintenance and training, industrial facilities can enhance valve efficiency, contributing to overall operational effectiveness.

Top 10 Types of Valves: Unlocking Key Insights for Industrial Efficiency

| Valve Type | Function | Common Applications | Maintenance Tips | Expected Lifespan (Years) |

|---|---|---|---|---|

| Gate Valve | On/Off flow control | Water supply, oil pipelines | Regular lubrication, inspect for leaks | 10-50 |

| Globe Valve | Regulating flow | Steam, water, oil systems | Check for corrosion, clean seats | 10-30 |

| Ball Valve | Quick shut-off | Natural gas, water services | Ensure proper sealing, avoid over-tightening | 15-30 |

| Check Valve | Prevents backflow | Pumping stations, piping systems | Inspect for debris, check for leaks | 20-30 |

| Butterfly Valve | Throttle flow | Chemical handling, water treatment | Check operation regularly, grease regularly | 10-25 |

| Plug Valve | On/Off control | Fuel and oil services | Inspect seals, clean with suitable solvents | 15-25 |

| Pressure Relief Valve | Prevent overpressure | Boilers, pressure vessels | Test regularly, ensure freeing of the disk | 5-15 |

| Solenoid Valve | Automated control | Irrigation systems, HVAC | Maintain electrical connections, check for clogs | 5-20 |

| Float Valve | Level control | Tanks, elevated reservoirs | Regular inspection and cleaning, check float operation | 10-20 |

Related Posts

-

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

-

Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications

-

Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers