Top Types of Ball Valves for Industrial Applications?

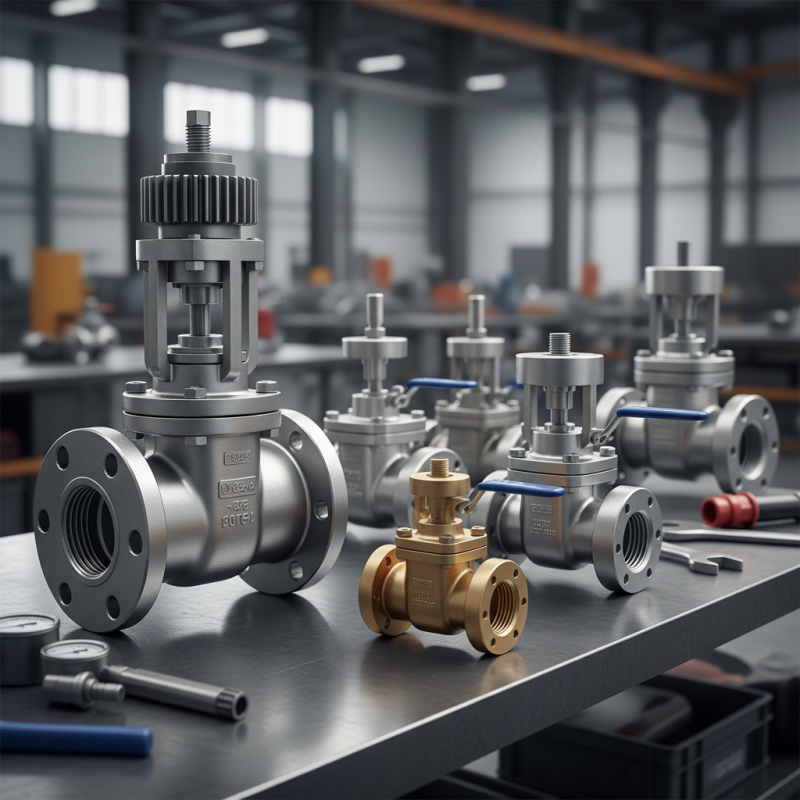

In industrial applications, ball valves are critical components. These valves are known for their efficiency in regulating flow. According to a recent market report, the global ball valve market is projected to grow significantly, reaching $20 billion by 2025. This growth is driven by rising demands in oil and gas, water treatment, and chemical industries.

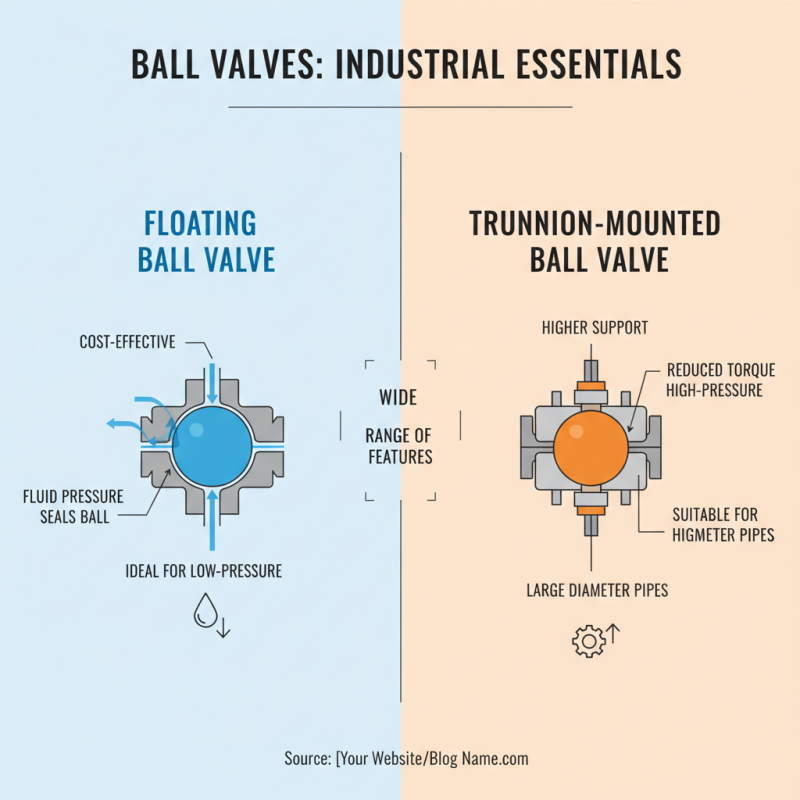

Different types of ball valves serve unique functions. For instance, trunnion-mounted ball valves offer enhanced sealing for high-pressure applications. Floating ball valves, on the other hand, are preferred in low-pressure systems. Although these distinctions are notable, many industries still struggle with choosing the right type. This often leads to inefficiencies and increased operational costs.

There is also a growing awareness of the importance of quality in ball valve selection. Poor-quality valves can lead to leaks and system failures. A detailed analysis of valve performance reveals that investing in high-quality ball valves pays off in the long run. However, the lack of knowledge about these types can hinder progress. Industries must reflect on their choices to ensure optimal operations.

Overview of Ball Valve Types in Industrial Settings

In industrial settings, ball valves are essential for controlling fluid flow. Their compact design and reliable performance make them a top choice. According to a recent industry report, the global market for ball valves is expected to grow at a CAGR of 4.6% from 2021 to 2028. This reflects an increasing demand across various sectors.

Different types of ball valves serve distinct purposes. Floating ball valves are common in applications with low pressure. They offer a simple, cost-effective solution. Trunnion-mounted ball valves, on the other hand, handle high pressure and larger pipe sizes. They are more complex but necessary for industrial operations that require high reliability. A study indicates that trunnion-mounted valves can reduce torque by 30% compared to floating types in high-pressure systems.

However, choosing the right valve is not straightforward. Factors like fluid type, pressure, and temperature must be considered. Miscalculations can lead to valve failure or inefficient operation. Industry experts note that 20% of installations fail due to improper valve selection. This highlights the need for thorough analysis before implementation. Many professionals still overlook these aspects, leading to costly downtime.

Key Features and Advantages of Different Ball Valves

Ball valves are essential in various industrial applications. They offer a wide range of features to suit different needs. Two popular types are floating ball valves and trunnion-mounted ball valves. Floating ball valves are cost-effective and simpler in design. They rely on the pressure of the fluid to hold the ball against the seat, ensuring a tight seal. These are well-suited for low-pressure applications.

On the other hand, trunnion-mounted ball valves are designed for higher pressure and larger pipe sizes. They contain a shaft that supports the ball, reducing the seat wear. This design enhances durability and reliability. Users often appreciate this when working with corrosive or abrasive materials. The drawback? They can be more expensive and complex to install.

Each type of ball valve has advantages and limitations. Understanding these helps in making informed choices. Balancing cost, efficiency, and application requirements is crucial for optimal performance. Ensure to evaluate your specific needs before deciding. It's essential to remember that the best choice varies by each operation’s context.

Applications of Ball Valves in Various Industries

Ball valves play a critical role across various industries. In oil and gas, they control flow with high reliability. These valves can handle pressures up to 6000 psi, making them suitable for extreme environments. According to industry reports, around 50% of companies in this sector prefer ball valves for their durability and low maintenance.

In the water treatment sector, ball valves are essential. They provide quick shut-off capabilities, crucial for preventing leaks. The National Water Association notes that improper sealing can lead to contamination. A study showed that nearly 30% of water treatment facilities experienced issues due to valve failures. Regular inspections are vital here.

Moreover, in the manufacturing industry, ball valves regulate the flow of various fluids. They ensure consistent product quality. However, not all ball valves are created equal. Some may fail under specific conditions, leading to production delays. A 2022 survey indicated that 40% of manufacturers reported valve-related downtime. These problems highlight the need for regular assessment of valve performance parameters.

Comparison of Materials Used in Ball Valves

When choosing ball valves for industrial applications, material selection is crucial. Common materials include stainless steel, brass, PVC, and bronze. Each has unique properties that affect performance and longevity. For instance, stainless steel is highly resistant to corrosion and can withstand high pressures. According to industry data, over 60% of valves used in chemical processing are made from stainless steel due to its durability.

Brass valves are cost-effective and good for low-pressure applications. However, they can corrode when exposed to harsh chemicals. PVC ball valves are lighter and resist corrosion well, making them suitable for water systems. Yet, they may not perform well in high-temperature conditions. Bronze offers excellent strength and resistance to saltwater but can be expensive.

Tips:

- Always consider the operating environment and fluid type.

- If you deal with corrosive substances, avoid brass.

- Regular inspection of valve conditions can prevent unexpected failures.

- Expect that not every valve will last forever.

- Materials can degrade over time, and some might not perform as expected under specific conditions.

- Performing thorough research on materials can help make better decisions.

Maintenance and Operational Considerations for Ball Valves

Ball valves are widely used in various industrial applications due to their reliability and efficiency. However, proper maintenance is crucial for optimal performance. Regular inspections should be conducted to identify any signs of wear or damage. A simple visual check can reveal leaks or corrosion. Operators must ensure that the valve seats and seals are intact, as these components are critical for preventing leaks.

Lubrication is another key factor in maintaining ball valves. Appropriate greasing of the stem and other moving parts can prevent friction. However, excessive lubrication can cause issues too. It's important to find the right balance. Operators often overlook the need for routine testing of the valves under working conditions. This step helps to confirm that the valve closes and opens smoothly.

In addition, monitoring the operating environment is essential. Factors like temperature and pressure fluctuations can affect valve performance. Operators should be aware of their specific conditions. Tracking changes can help prevent unexpected failures. It's not uncommon for operators to neglect these details until a problem arises. This oversight can lead to costly downtime and repairs.

Related Posts

-

Why Are Ball Valves Essential for Modern Plumbing Systems?

-

2025's Top 5 Ball Valve Innovations for Efficient Fluid Control Systems

-

Understanding the Key Benefits of Using Ball Valves in Modern Plumbing Systems

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Understanding the Importance of Control Valves in Modern Industrial Applications

-

Top 10 Tips for Choosing the Right Check Valve for Your Project