The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

In today's industrial landscape, the importance of selecting the right flow check valve cannot be overstated. According to a recent report by the Global Market Insights, the flow check valve market is projected to exceed USD 5 billion by 2026, driven by the rising demand for efficient fluid control systems across various sectors, including oil and gas, water treatment, and manufacturing. As processes become more complex and the need for reliable operational efficiency intensifies, understanding the various types of flow check valves available is crucial.

These valves play a critical role in preventing backflow, ensuring the safety and integrity of system operations. Consequently, knowing how to choose the appropriate flow check valve tailored to specific system needs is essential for optimizing performance and minimizing downtime in any industrial application.

Understanding the Basics of Flow Check Valves and Their Functionality

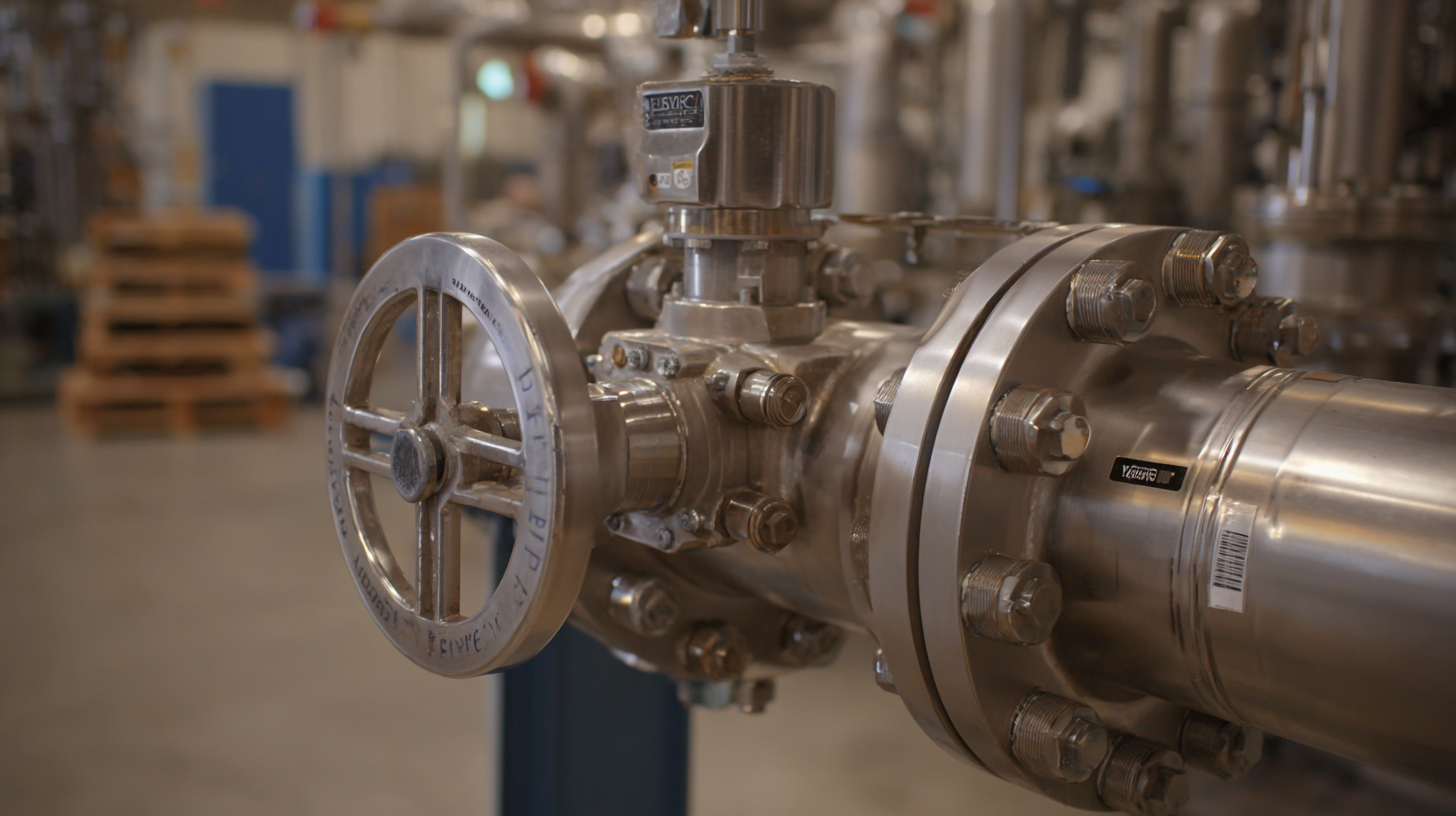

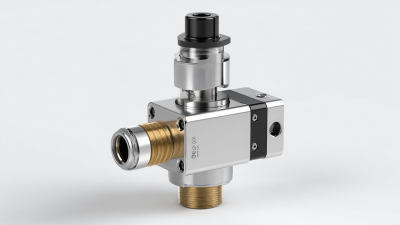

Flow check valves are crucial components in various fluid systems, designed to allow flow in one direction while preventing backflow. These devices play a vital role in maintaining system efficiency and protecting equipment from damage due to reverse flow. Understanding their functionality begins with recognizing their mechanical design, which typically includes a movable element such as a ball or disc that seals against a seat when backpressure occurs. This simple yet effective design ensures that fluids move smoothly in the intended direction while safeguarding the integrity of the system.

When selecting a flow check valve, it is essential to consider the specific requirements of your system, such as pressure ratings, flow rates, and the type of fluid being handled. Valve materials should also be compatible with the media to prevent corrosion or other forms of degradation. Furthermore, the installation orientation can affect performance; some valves operate more effectively when installed in a vertical position. By understanding these basic principles and functionalities of flow check valves, users can make informed decisions that will enhance the reliability and efficiency of their fluid systems.

Key Considerations for Selecting the Right Flow Check Valve

When selecting the right flow check valve for your system needs, several key considerations must be taken into account. Firstly, understanding the fluid characteristics is essential. Factors such as viscosity, temperature, and corrosiveness can significantly influence the type of valve materials and design that would be appropriate. For instance, corrosive fluids may require valves made from stainless steel or other resistant materials to ensure longevity and performance.

Another crucial aspect to consider is the flow direction and pressure requirements of your system. Different applications may necessitate specific designs, such as swing check valves for low-pressure systems or spring-loaded check valves for higher-pressure scenarios. Additionally, it’s important to evaluate the size of the valve in relation to your pipeline dimensions, as this will directly affect the efficiency and effectiveness of the valve’s operation. By carefully assessing these factors, you can ensure that your chosen check valve will operate reliably, enhancing the overall performance of your system.

Comparing Different Types of Flow Check Valves for System Compatibility

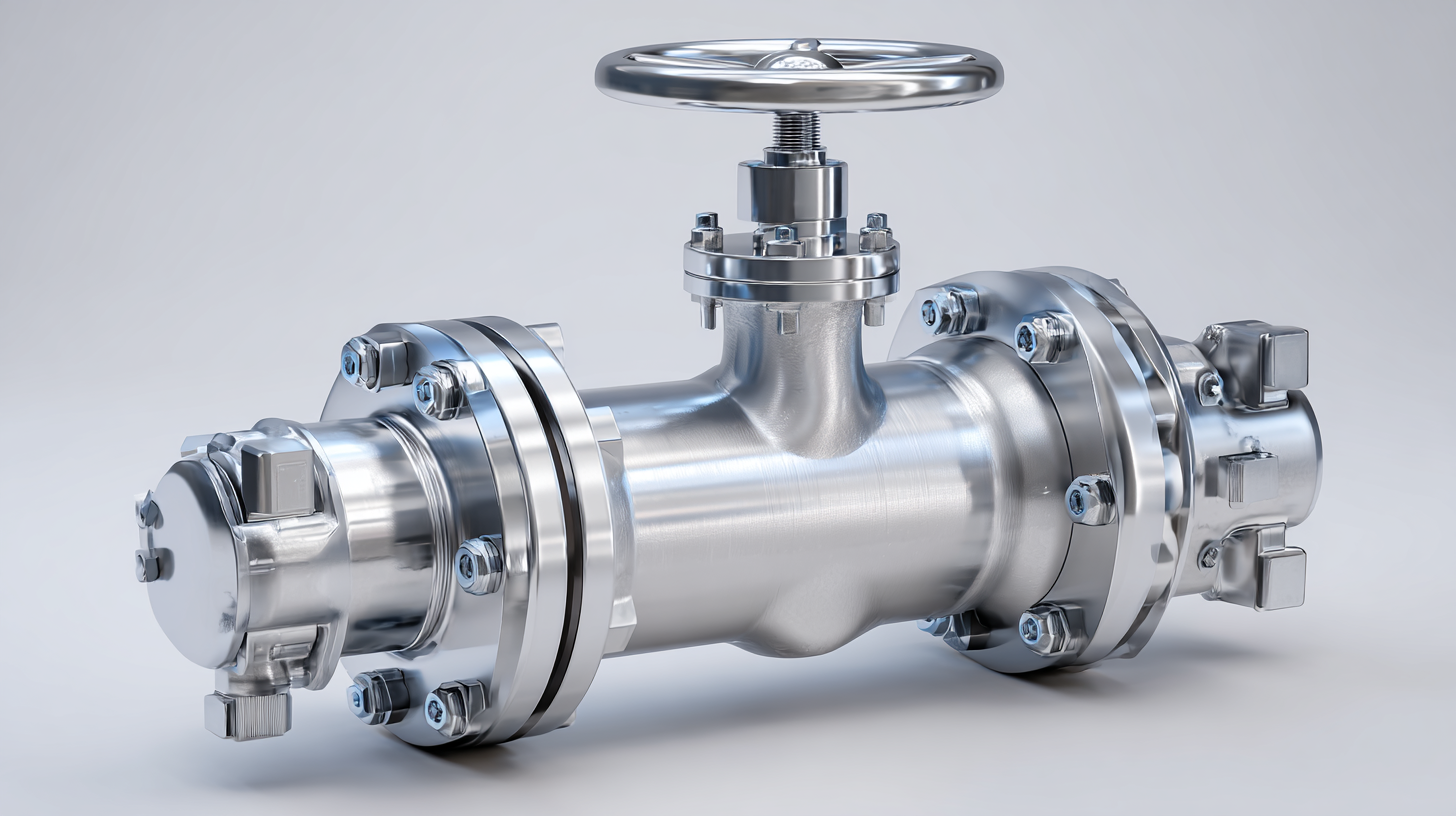

When selecting a flow check valve for your system needs, it's essential to compare the various types available to ensure compatibility with your specific applications. There are several common types of check valves, including ball, swing, and diaphragm check valves, each with distinct advantages and limitations.

Ball check valves are known for their simplicity and effectiveness in lower pressure systems, while swing check valves are ideal for larger flow rates and are often used in applications where backflow prevention is crucial. Diaphragm check valves, on the other hand, offer excellent sealing capabilities, making them suitable for sensitive processes.

Compatibility also extends to the valve material and the working environment. Metal check valves are robust and can handle high-pressure systems, whereas plastic alternatives provide resistance to corrosive substances. Additionally, the connection type – whether flanged, threaded, or welded – must match the existing infrastructure of your system. By evaluating the operational demands and environmental conditions, you can make an informed decision that ensures optimal performance and longevity of your flow control mechanism.

Assessing Material and Size Options for Optimal Performance

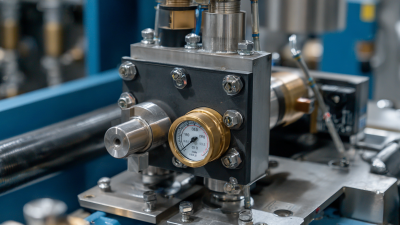

When selecting a flow check valve, material and size are crucial factors that directly impact the valve's performance and longevity. Different environments and applications necessitate specific materials to ensure optimal durability and resistance to corrosion, pressure, and temperature fluctuations. For instance, stainless steel is often favored for its strength and resistance to a variety of chemicals, while plastic options may be more suitable for non-corrosive applications and lighter installations. Evaluating the media that will flow through the valve will help narrow down the best material to use.

In addition to material, the size of the flow check valve must match the system's dimensions and flow requirements. An incorrectly sized valve can lead to inefficiencies such as pressure drops, excessive turbulence, or even valve failure. To ensure proper sizing, it’s essential to consider the diameter of the piping and the flow rate of the system. Utilizing manufacturer data and flow characteristics will provide the guidance needed to select a valve that not only fits but also enhances the performance of the entire system.

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

| Material | Size (Inches) | Pressure Rating (psi) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Stainless Steel | 2" | 150 | -20 to 300 | Water, Oil |

| PVC | 1.5" | 100 | 32 to 140 | Chemical Processing |

| Brass | 3" | 200 | -4 to 180 | Compressed Air |

| Cast Iron | 4" | 250 | -20 to 400 | Steam, Water |

| Aluminium | 6" | 150 | -40 to 200 | Petrochemical |

Maintenance Tips for Ensuring Longevity of Your Flow Check Valve

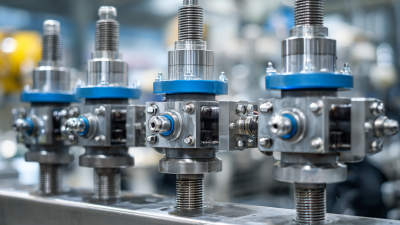

When it comes to maintaining the longevity of a flow check valve, regular inspection and upkeep are paramount. According to a report by the Hydraulic Institute, nearly 30% of valve failures can be attributed to inadequate maintenance practices. Therefore, implementing a routine maintenance schedule can significantly enhance the lifespan of your flow check valve and ensure optimal performance in your system.

One important maintenance tip is to regularly check for leaks and signs of wear, especially in high-pressure environments. A study published by the American Society of Mechanical Engineers (ASME) indicates that approximately 22% of flow control issues are linked to degraded sealing surfaces. Additionally, cleaning the valve regularly to remove debris and sediment buildup can prevent premature failure. The American Water Works Association reports that keeping flow check valves free from obstruction can improve efficiency by up to 15%, ensuring your system operates smoothly over time. Following these tips not only extends the life of the valve but also contributes to the overall efficiency and reliability of the fluid system.

Related Posts

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China