The Ultimate Guide to Vacuum Relief Valves for 2025 Top Applications

As industries continue to prioritize safety and efficiency, vacuum relief valves have emerged as critical components in various applications, ensuring the protection of equipment and maintaining operational integrity. According to a recent report by the Global Industry Analysts, the vacuum relief valve market is projected to grow significantly, driven by increasing demand across sectors such as chemical processing, pharmaceuticals, and food and beverage. The application of vacuum relief valves plays a vital role in preventing vacuum conditions that can lead to structural damage, product contamination, and costly downtime.

In 2025, the significance of vacuum relief valves will be more pronounced, given the anticipated advancements in technology and stricter regulatory standards worldwide. Industries are expected to adopt more sophisticated vacuum relief systems that not only enhance safety but also improve process efficiency. Research indicates that improper vacuum pressure management can result in up to 30% of equipment failure in certain industries. As such, understanding the top applications for vacuum relief valves will be essential for engineers and safety professionals to navigate the complexities of modern industrial operations while ensuring compliance and operational continuity.

The Importance of Vacuum Relief Valves in Industrial Applications

Vacuum relief valves are critical components in a wide range of industrial applications, ensuring the safe and efficient operation of systems that handle fluids and gases. Their primary function is to protect tanks, vessels, and pipelines from the detrimental effects of vacuum conditions, which can lead to structural damage, leakage, or even catastrophic failure. According to a report from the International Society of Automation, improper management of vacuum conditions has been linked to up to 40% of mechanical failures in industries like oil and gas, pharmaceuticals, and food processing. This underscores the importance of integrating reliable vacuum relief valves into operational protocols.

In addition to safeguarding equipment, vacuum relief valves also play a vital role in maintaining process efficiency and environmental compliance. The American National Standards Institute highlights that improperly designed vacuum systems can result in significant product losses and increased emissions. For instance, the introduction of advanced vacuum relief technologies has shown to improve operational efficiencies by up to 20%, facilitating better resource management and contributing to sustainability goals. This trend is expected to rise as industries increasingly adopt automated solutions and smart technologies in their operations, emphasizing the growing significance of vacuum relief valves in modern industrial practices.

Key Industries Utilizing Vacuum Relief Valves: A 2025 Overview

Vacuum relief valves play a crucial role in various industries by maintaining optimal pressure levels and preventing vacuum conditions that can lead to equipment damage or inefficiencies. In the chemical processing industry, these valves are essential for regulating the internal pressure of storage tanks and reactors, especially during filling and emptying operations. By allowing controlled air intake, they prevent excessive vacuum from forming, which could compromise the integrity of containment systems and result in hazardous situations.

In the food and beverage sector, vacuum relief valves are increasingly utilized to ensure the safety and quality of products. They manage the pressure within storage and processing vessels, protecting them from collapse when liquid is removed or during thermal changes. Additionally, in pharmaceutical manufacturing, these valves contribute to the integrity of production processes by protecting sensitive materials from contamination and preserving sterile environments during packaging.

As industries continue to evolve, the application of vacuum relief valves remains vital in promoting safety, efficiency, and product quality across diverse sectors in 2025 and beyond.

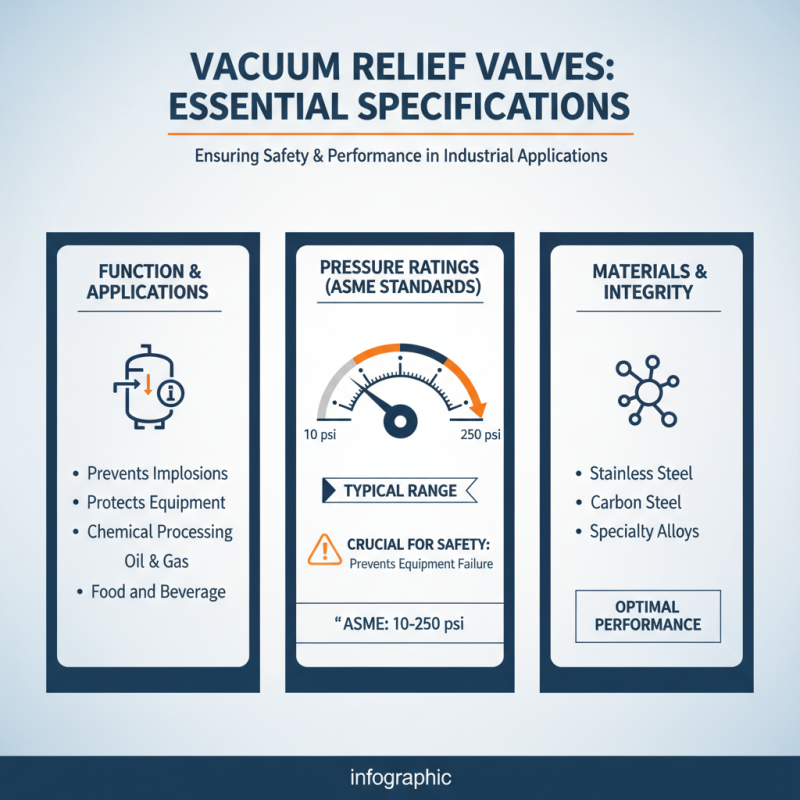

Technical Specifications: Understanding Pressure Ratings and Materials

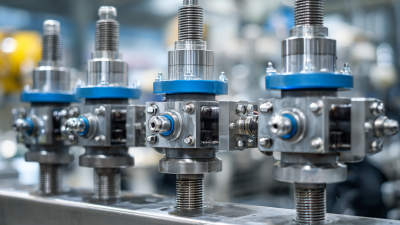

Vacuum relief valves (VRVs) are essential in many applications, particularly in industries such as chemical processing, oil and gas, and food and beverage. Understanding the technical specifications surrounding pressure ratings and materials is crucial for ensuring optimal performance and safety standards in these settings. According to the American Society of Mechanical Engineers (ASME), the pressure rating of vacuum relief valves typically ranges from 10 psi to 250 psi, which determines the valve's ability to withstand specific pressure conditions without compromising integrity. Selecting the appropriate pressure rating is vital, as inadequate ratings can lead to dangerous situations such as implosions or equipment failure.

Materials used in vacuum relief valves can significantly impact their performance and longevity. For example, stainless steel is widely favored for its corrosion resistance and strength, while plastic materials may be utilized in less demanding applications due to their lighter weight and cost-effectiveness. A recent industry report from the Global Valve Market highlighted that valves made from high-performance alloys are projected to see a growth rate of 5% annually as industries seek enhanced durability in challenging environments. Understanding the interplay between pressure ratings and material selections will enable engineers and operators to mitigate risks and optimize operations in 2025 and beyond.

Impact of Regulatory Standards on Vacuum Relief Valve Design

Vacuum relief valves are critical components in safeguarding systems from negative pressure conditions, ensuring operational safety across various industries. The design of these valves is increasingly influenced by stringent regulatory standards aimed at enhancing safety and efficiency. According to the latest report by the American Society of Mechanical Engineers (ASME), regulations such as the API 2000 ensure that vacuum relief valves meet specific performance criteria to mitigate risks associated with atmospheric pressure fluctuations. As a result, manufacturers are required to incorporate innovative design elements that not only comply with these standards but also improve reliability and maintenance processes.

Moreover, the evolving landscape of environmental regulations is driving the development of vacuum relief valves that prioritize sustainability. The International Organization for Standardization (ISO) has introduced guidelines focused on minimizing emissions during the operation of these valves. For instance, it is estimated that incorporating advanced materials and sealing technologies can reduce leakage rates by up to 30%, aligning with the ISO 14001 environmental management standards. These shifts not only enhance the safety profile of vacuum systems but also contribute to the overall efficiency and sustainability of operations in sectors such as oil and gas, pharmaceuticals, and food processing. Thus, the interplay between regulatory frameworks and technological advancements will continue to shape the future of vacuum relief valve design.

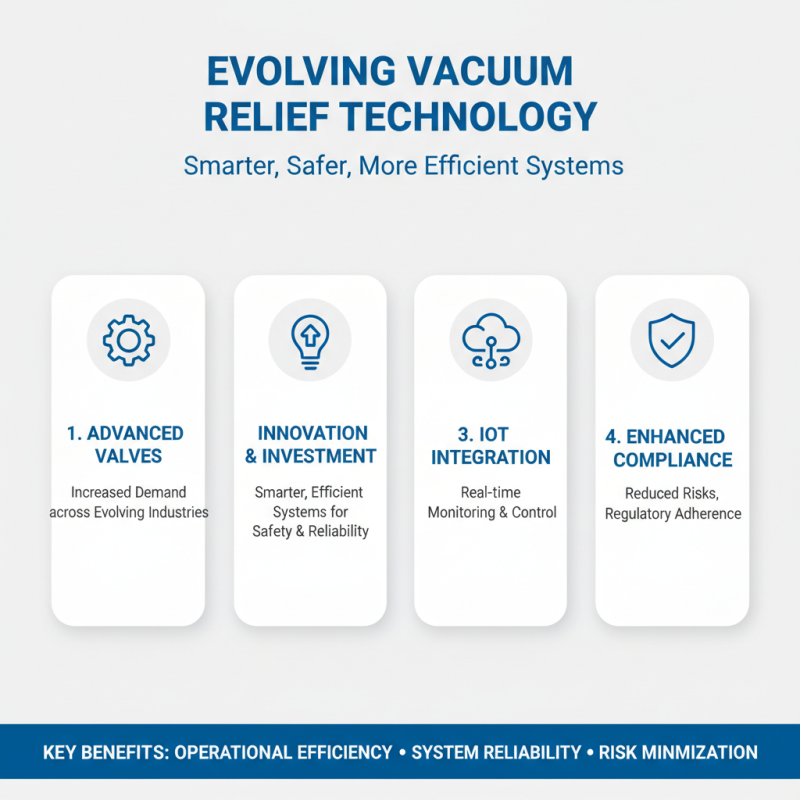

Future Trends: Innovations and Developments in Vacuum Relief Technology

As industries evolve, the demand for advanced vacuum relief valves has surged, necessitating innovative developments in vacuum relief technology. Companies are investing in smarter, more efficient systems that enhance the safety and reliability of operations. The integration of IoT (Internet of Things) technology is a significant trend, allowing real-time monitoring and control of vacuum levels. This not only improves operational efficiency but also ensures compliance with increasing regulatory standards, thus minimizing the risks of equipment failure and system overload.

Another noteworthy trend is the focus on sustainable materials and manufacturing processes. As environmental considerations take precedence in engineering design, the development of vacuum relief valves using recyclable materials is becoming more common. Moreover, advancements in computational fluid dynamics (CFD) are enabling more precise modeling and testing of these valves, leading to superior designs that optimize performance while reducing energy consumption. This commitment to sustainability and innovation is paving the way for vacuum relief technology to meet the challenges of modern industrial applications, ensuring that safety and efficiency go hand in hand.

Related Posts

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Why Choosing the Right Pressure Relief Valve is Essential for Safety and Efficiency

-

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

-

Why Choosing Stainless Ball Valves is Essential for Your Industrial Applications

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications