Ultimate Guide to Valve Tags in 2025 Trends and Best Practices

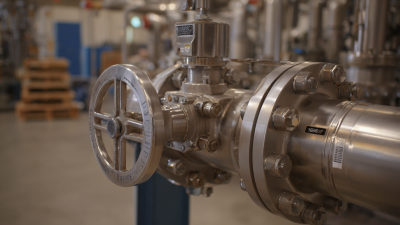

In the ever-evolving landscape of industrial safety and efficiency, the importance of effective valve tagging cannot be understated. As we delve into the trends and best practices of valve tags in 2025, we turn to industry expert Dr. Emily Carter, a leading authority in industrial safety protocols. Dr. Carter emphasizes, “Effective valve tags not only streamline operations but also significantly enhance safety measures within facilities.” With her insights, we can understand the critical role that valve tags play in ensuring operational continuity and safety.

In recent years, the focus on standardized valve tags has intensified, driven by advancements in technology and growing regulatory requirements. Companies are increasingly recognizing that clear and concise valve tagging not only improves communication among team members but also minimizes the risks associated with valve mismanagement. By implementing strong valve tag practices, organizations can ensure that their operations are not just compliant but also optimized for safety and efficiency.

As we explore the ultimate guide to valve tags in 2025, it is crucial to embrace these evolving trends and practices. By doing so, we can anticipate better responsiveness to operational challenges while ensuring the highest standards of safety are upheld.

Overview of Valve Tags: Definition and Importance in 2025

Valve tags play a critical role in various industrial settings, serving as essential tools for identification, organization, and safety. As we navigate through 2025, the significance of valve tags is more pronounced than ever. These tags not only provide crucial information regarding the function and status of valves but also contribute to streamlined operations and enhanced safety protocols. In a world where efficiency and safety are paramount, clear labeling is vital to prevent mishaps and ensure proper maintenance of equipment.

When implementing valve tags, consider these tips for maximizing their effectiveness. First, ensure that all tags are made from durable materials suitable for the environment in which they are used—whether that be extreme temperatures, moisture, or chemicals. Secondly, employ a standardized color-coding system to facilitate quick recognition and easier navigation through complex systems. Finally, regularly review and update the information on the tags to reflect changes in system configuration or maintenance procedures, ensuring that all personnel have access to accurate and up-to-date information.

As 2025 unfolds, the integration of technological advancements, such as QR codes or digital tagging systems, can further enhance the utility of valve tags. These innovations offer quick access to detailed information and maintenance histories, which can significantly improve response times during critical situations.

By embracing these best practices, industries can better safeguard their operations and maintain the efficiency necessary for success in today's fast-paced environment.

Current Trends in Valve Tag Design and Technology for 2025

In 2025, the design and technology of valve tags are evolving rapidly, driven by the need for enhanced durability and operational efficiency. One key trend is the increased use of advanced materials that withstand harsh environments, including extreme temperatures and corrosive substances. These innovations are ensuring that valve tags can maintain legibility and integrity over time, which is crucial for safety and maintenance protocols.

Additionally, the incorporation of RFID technology is gaining traction, enabling automatic tracking and data collection directly associated with valve operations.

Another significant development in valve tag design is the push for greater customization options. As industries demand more tailored solutions, manufacturers are offering valve tags that can be easily personalized with specific information, colors, and graphics to suit different operational contexts. This customization not only aids in quick identification but also promotes better compliance with industry regulations. Furthermore, the integration of digital solutions is on the rise, with smart tags that can communicate real-time data about valve status, thereby improving monitoring and reducing downtime risks. These advancements are set to revolutionize the way organizations manage their valve systems, leading to improved safety and efficiency in operations.

Best Practices for Implementing Valve Tags in Industrial Settings

In 2025, the implementation of valve tags in industrial settings is anticipated to become more vital for operational efficiency and safety. As industries strive to enhance their asset management and maintenance protocols, standardized valve tagging remains a best practice. Research shows that proper valve identification can reduce the time spent on maintenance tasks by up to 30%, leading to significant productivity gains. Keeping accurate records of valve operations through tagging ensures compliance with safety regulations and reduces the risk of accidents.

When implementing valve tags, it’s essential to consider the material and design of the tags. Tags should be durable enough to withstand harsh environmental conditions, including extreme temperatures and exposure to chemicals. According to industry standards, tags made of corrosion-resistant materials can last up to five times longer than standard plastic tags in industrial contexts. This durability not only saves costs on replacements but also ensures consistent visibility and readability, which are crucial for safe operations.

**Tip:** Use color-coded tags to easily distinguish between different types of valves or systems, which can enhance quick identification during maintenance activities.

**Tip:** Regularly review and update the tagging system to incorporate new technologies and ensure that all personnel are trained to understand and utilize the tagging system effectively. This continuous improvement will not only enhance safety protocols but also promote a culture of responsibility and awareness among workers.

Valve Tag Implementation Trends in 2025

Compliance and Regulatory Standards for Valve Tags in 2025

In 2025, compliance and regulatory standards for valve tags will become increasingly stringent as industries strive to enhance safety and operational efficiency. Proper tagging of valves not only aids in maintenance and troubleshooting but is also essential for adhering to regulations set by various governing bodies. These regulations often dictate specific information that must be present on valve tags, including material specifications, operating conditions, and safety protocols.

To ensure compliance, organizations should regularly review industry-specific standards and integrate them into their operational practices. Staying updated on changes in legislation is crucial, as non-compliance can result in costly penalties or safety violations. Regular audits of valve tags and their adherence to current regulations will help maintain an efficient workflow and promote accountability within teams.

**Tips for Compliance:**

1. Always check the latest industry regulations related to valve tagging and update your tags accordingly.

2. Train personnel on the importance of proper valve identification and adherence to safety guidelines.

3. Implement a regular schedule for reviewing and replacing valve tags to ensure they remain legible and compliant with all standards.

Future Innovations: What to Expect for Valve Tags Beyond 2025

As we look beyond 2025, the evolution of valve tags is likely to be driven by advancements in technology and increasing demands for operational efficiency and safety. Innovative materials and designs will enhance durability and visibility, ensuring that valve tags can withstand harsh environments while remaining easy to read. Additionally, the integration of digital technologies such as QR codes or RFID tags will allow for real-time monitoring and tracking of valve statuses, significantly improving maintenance protocols.

Tips: When selecting future valve tags, consider their compatibility with smart technology. Ensure that they can be easily scanned or read with mobile devices, facilitating quick access to valve information. Opt for materials that resist corrosion and fading to guarantee long-term visibility and compliance with safety regulations.

The focus on customization will also intensify, allowing facilities to tailor valve tags to specific operational needs. Expect personalized color coding and symbols that align with unique industry standards, which will improve safety and reduce human error. Collaborating with stakeholders during the design process will yield tags that better meet the user experience.

Tips: Involve your team in the design discussion to choose color schemes and symbols that everyone understands. This collaboration will not only enhance compliance but also increase the likelihood of proper usage in the workplace.

Related Posts

-

Top 10 Essential Valve Tags for Efficient Industrial Safety Management

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

-

How to Choose the Right Air Valve for Your Pneumatic System Needs

-

What is an Electronic Valve and How Does it Work in Modern Systems

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance